Synopsis: We woodworkers are crazy about accuracy, but we tend to rely on test cuts when fitting joinery, eyeballing blade heights and using trial-and-error to get cuts just right. Richard Babbitt has moved away from test cuts, instead using a $40 height gauge, a tool most often used in metalwork. Use it for woodworking, and the depth of your tablesaw blade will always be on the money, your jointer will be tuned to perfection, and you’ll set up the fussiest router bit quickly and precisely.

To make using a height gauge even easier, we’ve compiled a handy Fraction Conversion Chart.

Watch a video on using the height gauge

From Fine Woodworking #218

Woodworkers can be a contradictory bunch. While we crave accuracy a machinist would envy, we seek it in curious ways: tapping tablesaw fences with the hand, eyeballing blade heights, and relying on those curious units of measurement, smidgens and tads. As a result, every machine setup requires a bucketful of test cuts.

There’s a better way. While most woodworkers are familiar with the dial caliper, its cousin, the height gauge, has mainly been confined to metalworking. However, I think you’ll be amazed at what this little $40 wonder can accomplish in a woodworking shop. With it, your depth of cut on the tablesaw will always be on the money, your jointer will be tuned to perfection, and you’ll set up the fussiest router bit quickly and precisely.

Once you start using a height gauge, you’ll wonder how on earth you worked wood without one. The only drawback is that without test cuts, I now have a shortage of kindling for my fireplace.

Precision at a glance You’ll get absolute accuracy if you use a height gauge for every vertical measurement. And you won’t need the eyes of a hawk. I have a difficult time reading 1⁄64 in. on a ruler. However, setting the height gauge to within 0.001 in. is easy. Even if, like me, you’re not an engineer, I hope the examples in this article will inspire you to put a height gauge to work in your shop.

No more routertable test cuts. Using the height gauge, router-cut rabbets and dadoes can be set to an exact depth, slot-cutting bits can leave a groove precisely bisecting the thickness of the workpiece, and joint-making bits such as the reverse-glue-joint and lock-miter bits can be set up right the first time.

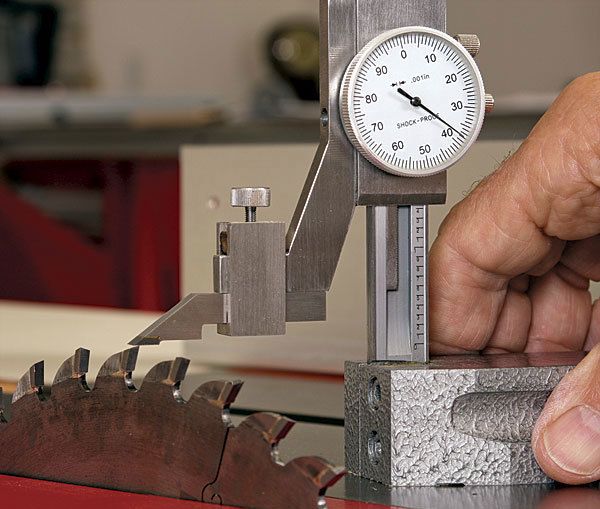

Exact blade heights. Very few tablesaws have a system to measure blade height, and using a rule or a combination square is not ideal. You can set the height gauge to the exact height you want the blade, and then raise the blade until the tip of a tooth just touches the probe. On a dado set, register the height of an inner chipper tooth, as they determine the core depth of the rabbet or dado, not the outside blades.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Veritas Micro-Adjust Wheel Marking Gauge

Starrett 4" Double Square

Suizan Japanese Pull Saw

Log in or create an account to post a comment.

Sign up Log in