Recycled Materials Make for One Great Budget Workbench

I was wandering around some estate sales in the fall and came across a few grand finds. First, I came upon an older Wilton vise that I thought would be great to have–just in case. It ended up being quite cheap and I couldn’t pass it up. Later, I found an old children’s play table and set of benches. It resembled a picnic table and was covered in a thick layer of plastic resin but was constructed in solid butcher block maple. The top was 1-3/4 in thick, 30 inches wide and 48 inch long. A perfect small bench was in the works for my garage workshop that I’m desperate to get together.

I took the table and bench apart and went about designing a sturdy base. The bench seats were cut to size for the base legs. A belt sander took care of the old finish there but it wouldn’t touch the plastic resin coating the table top. With a rough chisel and hammer, the thick plastic resin easily popped off the surface. I then purchased two 8/4 thick maple boards to make the feet and stretchers to complete the bench base.

|

More on Workbench Tech |

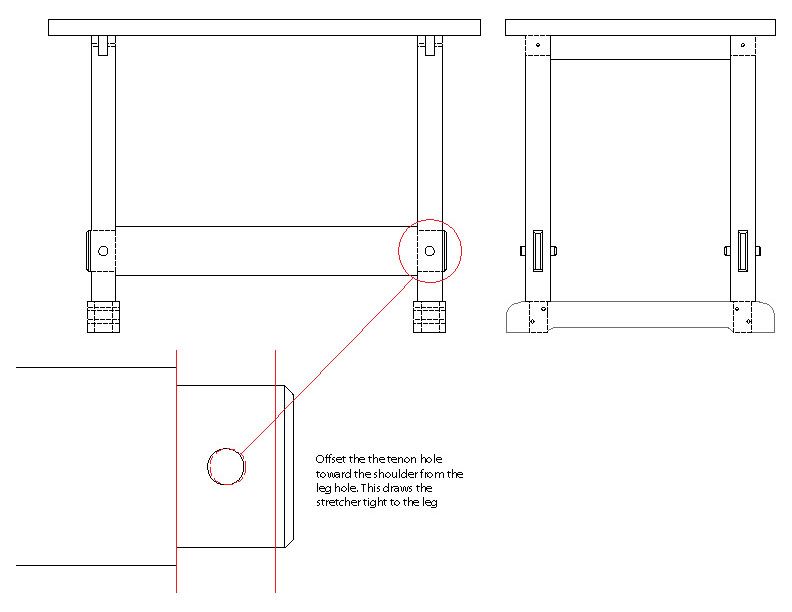

To keep the construction simple, strong, and fast, I decide to make all the leg and foot mortises on the tablesaw with a flat bottom cutting dado blade. I cut the dados with stop blocks to define the ends and made each piece identical to its mate. I glued up the halves to make both the legs and feet. I shaped the feet and glued and pegged all the joints for strength on the leg uprights. The stretchers were left unglued. Next, I made offset 1-in. holes and used a 1-in. diameter oak peg to pull the tenon shoulders tight to the legs. With the large size of these pieces, this joint is incredibly strong and I can knock down the bench should I ever have to move it. And I probably will. The top gets bolted to the leg assemblies with lag bolts.

All in all, I’ve spent less than $100 on this small bench and now I don’t have to rely on my tablesaw top for all my hand planing and assembly tasks. Now I just need to get the Wilton vise installed this weekend so I can forge ahead with some of the furniture projects I’ve been contemplating.

Comments

Now, all I have to do is go find all the same material at an estate sale so I can build one too! This is a completely useless blog.

This looks like a great, small bench. Easy enough to build even without any plans. It shows that with a little imagination one might be able to find the materials without buying a pile of new lumber. And with this design, even if you did have to buy the lumber, it wouldn't break the bank.

Thanks for a great idea. I'm going to look at the "treasures" at estate and garage sales a bit differently now.

Thanks for the post. It's good to be reminded that, regardless of the project, re-purposing lumber is always a good idea. Good work on the bench. Love to see it with the vise.

No, gsm627, it isn't a useless blog at all.

However, what is very annoying is finding out that when you print the article to a pdf file, the images are missing!

So, excellent article, shame about the back-up systems.

Kind regards - John Moran

Hi John_Moran: sounds like you need to update your Adobe Acrobat. Just checked the PDF files - and all load and print as they should.

Best,

Ed

A very nice little bench with a great vise for an even better price.

I made my first router table form a crummy desk left on the curb with a "free" sign attached. The top was 2" think MDF with a melamine finish.

Our county dump has a section for things people doon't want that still work. Local yard sale, etc. All great sources.

Hi John_Moran,

As far as I know - the ability for images that are in the gallery sectino at the top of posts to appear in "print-to-PDF" has never been available. In-line images - or images that appear within the body text-- do appear, however, this post only has gallery images.

Best,

Ed

No,gsm627,blogs like this makes your brain neurones wake up from letargy.

I have a question about using recycled materials for projects.

I recently came across 120 bf of long leaf pine which is 80-100 years old. It is painted. I have a couple of concerns:

1. the paint might be lead based. What is the best way to remove it and dispose of it. Is there a test for lead paint?

2. Can I run the boards through my planer to remove the paint and dispose of the sawdust or will that ruin the cutter heads?

Log in or create an account to post a comment.

Sign up Log in