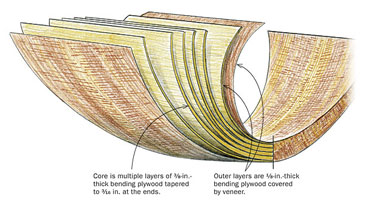

Lured by the dramatic look and technical challenges of curves, Enrico König (see the back cover) nearly always incorporates a deep bend in his furniture. The trick to pulling it off without sacrificing strength is to use laminations: The strength comes from the many layers and the rigid gluelines (urea resin glue or epoxy) between them. To avoid the arc looking clunky, he tapers it, and to do that without cutting through the plies, he tapers each one before laminating. König uses a tapering sled he saw in FWW #14 (Tapered Lamination by Jere Osgood; available at FineWoodworking.com/extras), putting solid-wood plies through a planer and bending plywood through a drum sander.

|

Simple sled. König uses a shopmade sled and a drum sander to taper the layers of bending ply. |

|

Glue, nail, and press. He uses a strong form with plywood ribs inside layers of bending ply glued and nailed on (left). He presses all the layers at once (right), including the veneer, using 1/8in. vinylcoated MDF cauls. Brads in the waste areas keep it all aligned. |

|

|

Crosscut first. Before cutting the sides of the lamination, he cuts its beveled ends. He does this on the tablesaw with a jig that holds the piece upright. |

|

Trace. For the curved sides, König uses a router on a pivoting arm to create a template, and then traces the curves onto the workpiece. |

|

Cut. Then he uses a jigsaw to cut away the waste. |

|

Finish. Last, he routs the edges clean with a topbearing bit and the same template |

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Comments

Wow...

Log in or create an account to post a comment.

Sign up Log in