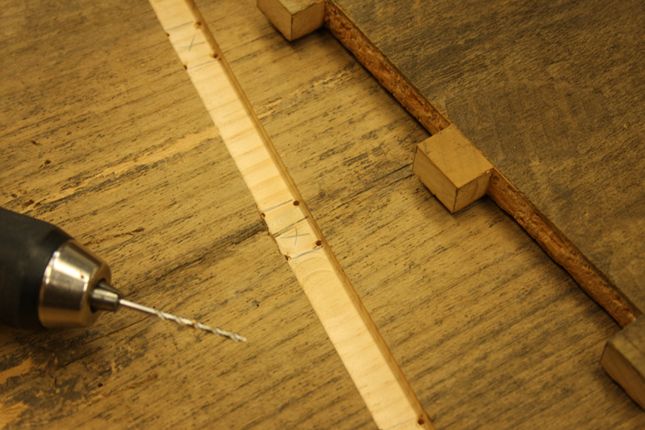

To cut the through-tenons on the shelves I simply clamped all of them together and used a hand saw to define the cheeks.

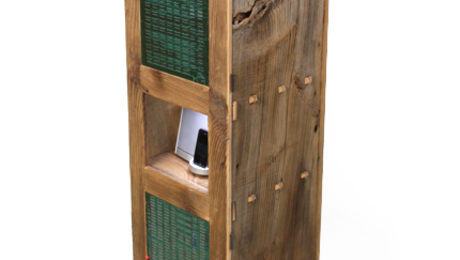

Furniture Lab Tech Cabinet – Part II

Follow along as Fine Woodworking associate art director John Tetreault constructs a cabinet using reclaimed materials found during our recent trek to southern Massachusetts.

Things are really beginning to speed up at this point of the Tech Cabinet build. The dados for the shelves have been cut in the case sides and the dovetails have been cut to accept the top. Next, I broke out the scrub plane to surface the interior shelves. The undulating surface that the scrub plane produces mimics the weathered exterior boards of the case sides. Browse through the photos above, where I show you how I made the through-tenons on the shelves and a little trick to cut mortises on the case sides when you want to keep the original patina of the wood.

Once the shelves were done, I was ready for the case glue-up. It was a little tricky with all those through-tenons, but I tackled the case first and then tapped home the dovetails on the top.

I’ll be back next week, with the conclusion of the project and plenty of final beauty shots!

|

More Projects by John Tetreault • The 3-Hour Cabinet |

Watch the Furniture Lab Junkyard Visit

Be sure to read Asa Christiana’s story outlining the original idea and intent of Furniture Lab, plus, watch our original Furniture Lab junkyard visit. John Tetreault, Tom McKenna, and Anatole Burkin visited an old salvage yard for some quirky design inspiration.

Comments

I can't wait to see the cabinet when it's done, especially the marks from the scrub plane. It's looking cool so far. Paul

Thanks Paul,

The scrub plane was a lot of fun to use. The texture is shallow enough to allow objects to sit flat on the shelf, but deep enough to have a great wavy feel to it. I should have the final construction photos up soon!

John

I recommend coating circuit boards with some kind of finish - you don't want to get lead on your hands every time you touch your cabinet or whatever...

The blog is unique that’s providing the nice material. Please post more interesting articles here.

read more

Log in or create an account to post a comment.

Sign up Log in