AWFS Tool News: Jet, Powermatic, and Delta Retool their Brands

Three big brands are set to go through some serious retooling this year.

As you might imagine, the prolonged recession has been a nightmare for manufacturers of stationary machines. Buyouts have consolidated the industry, with Black & Decker/DeWalt buying Delta/Porter-Cable, and then Stanley acquiring the whole lot, but soon peeling off, you guessed it, Delta, the brand that makes the largest machines, and selling it to a Taiwanese company, Chang Type Industrial Co.

As you might imagine, the prolonged recession has been a nightmare for manufacturers of stationary machines. Buyouts have consolidated the industry, with Black & Decker/DeWalt buying Delta/Porter-Cable, and then Stanley acquiring the whole lot, but soon peeling off, you guessed it, Delta, the brand that makes the largest machines, and selling it to a Taiwanese company, Chang Type Industrial Co.

The deal actually makes sense, since Chang Type already makes power tools for a number of well-known brands, including Craftsman, DeWalt, Ryobi, and Black & Decker, but the overseas management was a concern for many American woodworkers, if you read recent blogs and chatter.

No need to worry, said Delta’s new U.S. management staff, all veterans of the power-tool industry, including a few from the Delta of the 1990s. Mark Strahler is the new Delta’s director of product development. He left Delta about a decade ago to eventually launch Steel City.

Strahler and others outlined the relaunch strategy at a special AWFS press conference. They started by admitting the obvious, that the once-vaunted brand had been left to languish by former owners, with no real innovation other than the new Unisaw and a drill press or two. I could tell the Delta brand is close to Strahler’s heart, and is partly what brought him back to relaunch Delta and guide it going forward.

The new management plans a commonsense approach, working with existing models and factory tooling to fill out the Delta lineup, bringing back some solid tools that were recently canned by past management, but giving them some user-friendly tweaks to bring them up to date.

But what about innovation, many of us asked. Strahler was ready for that, showing us a prototype of e new Delta segmented cutterhead. I can’t disclose more than that, other than to say it looks like a very clever way to make one of these heads in a more cost-effective way, and Delta will be able to put it into every planer and jointer down to its 13-in. benchtop planers, and it will be available for retrofitting into many Delta models past and present.

What I can show you is a great new idea that will be in stores by 2012, a router table with a built-in motor and front-mounted controls, a “midi-shaper,” Delta is calling it. After seeing woodworkers try to assemble a shaper-like setup by spending over $1,000 on a big router, a router table, and an expensive router lift, Strahler thought, we can build it like a small shaper and give users all the benefits for less. The midi-shaper will have a router collet, variable speed between 6,000 and 30,000 rpm, and a shaper-style split fence, which can be offset for certain types of cuts, and the price tag will be in the $700-$800 range.

I also asked Strahler where he sees the new Delta brand fitting into the current marketplace. He said somewhere between Jet and Powermatic, meaning basically top-notch machines that have value in mind. Sounds like a good target to aim for.

WMH Stops the Bleeding So it can Innovate Again

Speaking of Jet and Powermatic, we also met with WMH’s Barry Schwaiger, director of product management. While there no brand-new machines to show us at the show, Schwaiger said WMH needed to focus first on becoming profitable again and being healthy going forward. So they made the company leaner, he said, and have freed up money for some true innovation in coming years.

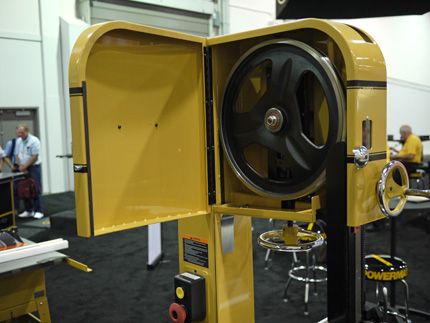

The company also clarified its vision for the two brands. The new model for Powermatic, for instance, will be zero-compromise, in the mode of Powermatic’s recent PM 1800 bandsaw, which Schwaiger designed from the ground up. “We’ll design it first, and then figure out what the cost will be,” he said. “If it doesn’t move the needle and distinguish itself in the market place, we won’t make it.” As an editor who sees so many companies filling out their product lines with me-too tools, this was music to my ears.

Schwaiger told us about three “marquee” Powermatic machines in the works for 2012, though I can’t tell you exactly what categories they are in. I can say that at least two of them are common ones that every shop has. Others are in the works too, as are innovations in the more value-oriented Jet line. Let’s all hope for a solid economic recovery. Schwaiger is a very smart tool developer, and his PM1800 is a great bandsaw, so I’m looking forward to his next big redesigns.

Comments

Was it Frank Zappa or Plato that said "Necessity is the mother of invention". It really doesn't matter who said it, but it's become very clear to manufactures world-wide that innovation sells even in a bad economy. Just look at the continued success of Apple. I think the wood working industry has been slow to accept that premise, but it's getting there.

The makers of major machines seem to have a problem understanding that some woodworkers will pay for innovation and quality. We are tired of machines that have to be reworked to make them run well. How about a Drill Press with a D.C. motor. An apple laptop is twice the price of a Dell and we buy apple laptops.

I totally agree about innovation being the answer, and I said as much to both of these companies.

I am all for progress along with innovation.It will be interesting to see the new line up of 2012 tools.Looking forward to it thehandtoolco.com

Yeah, as much as I like Delta, I'm a little upset with their management. Not only because of the juggleing of ownership in the last few years, but you talk about innovation. It's not like the old days, now Delta tries to make you jump through a bunch of expensive legal hoops before they will listen to anything. And I get the impression that they think they know more then the woodworker that actually uses the machines. I could of helped them improve the Contractor's saw, but no they would rather stick a bunch of money into redesigning and retooling a new breed of saw, the Hybrid, that ended up being a huge expensive flop from what I can tell. And look at them now, the only table saw on their website is a $3500 Unisaw. Are you kidding me ? In this economy do they really think that the average woodworker has the money for a $3500 table saw ? They have alot of work ahead of them to get customer loyalty back, if it isn't too late allready. But you know, no one can tell them that.

Looking at what Delta now calls a Contractor's table saw makes me think that the current Delta management and employees don't know what a contractor's table saw is, or why they were made when they were first introduced into the market. I also think that it looks too much like the JET Proshop, which I've never liked the style of, it looks cheap.

This is how you add value to products without haveing to go through the huge expense of redesigning a machine, and then jacking up the price to cover expenses. https://sites.google.com/site/sawsuckerproject/home The problem with woodworking nowdays is that less people are able to retire, and that the people that are working have less free time on their hands, plus woodworking isn't profitable enough to interest the younger generation. Throwing money at the problem by completely redesigning machinery isn't the answer. The companies in this country did it to themselves when they started sending jobs overseas, wakeup folks.

We are quickly reaching the half way point in 2012; any updates on when Powermatic may showcase these three "marquee" tools? I know I'm a little late on responding to your article Asa, but nice work as always.

Log in or create an account to post a comment.

Sign up Log in