Two Unique Lamps

Rings of veneer create style and ambience.

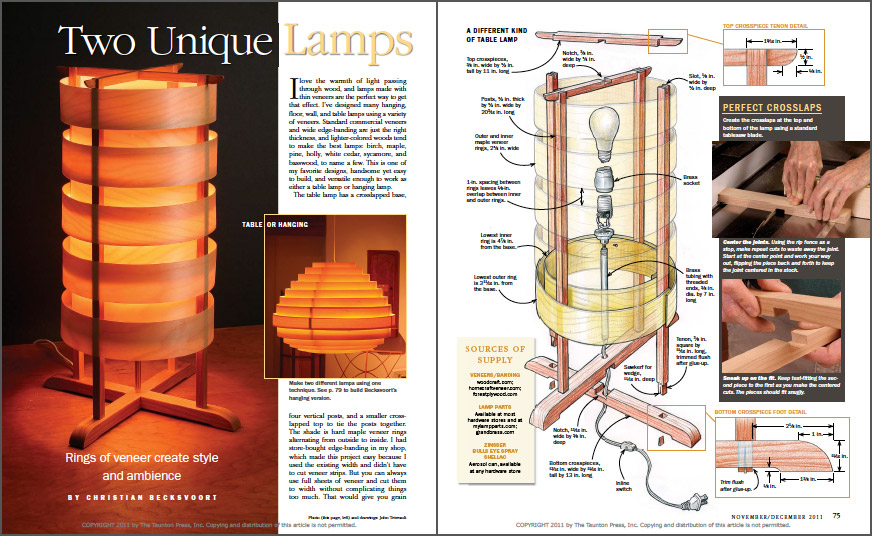

Synopsis: These handsome lamps, created with rings of veneer, will bring warmth to any room. The light shining through the overlapping rings creates a unique effect, and building the lamps is not difficult. This article details the standing version, with an alternative hanging version shown. The base and top are both crosslapped, joined by four posts. The shade is nine alternating rings of veneer. A simple formula makes calculating the length of the veneer strips easy.

I love the warmth of light passing through wood, and lamps made with thin veneers are the perfect way to get that effect. I’ve designed many hanging, floor, wall, and table lamps using a variety of veneers. Standard commercial veneers and wide edge-banding are just the right thickness, and lighter-colored woods tend to make the best lamps: birch, maple, pine, holly, white cedar, sycamore, and basswood, to name a few. This is one of my favorite designs, handsome yet easy to build, and versatile enough to work as either a table lamp or hanging lamp.

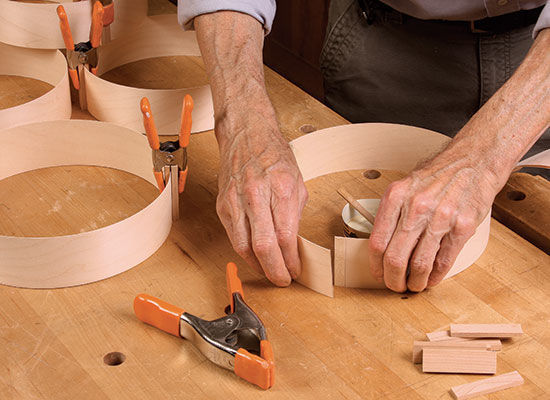

The table lamp has a crosslapped base, four vertical posts, and a smaller crosslapped top to tie the posts together. The shade is hard maple veneer rings alternating from outside to inside. I had store-bought edge-banding in my shop, which made this project easy because I used the existing width and didn’t have to cut veneer strips. But you can always use full sheets of veneer and cut them to width without complicating things too much. That would give you grain continuity along the height of the lamp and open up your wood choices.

Easy joints for the base and posts

I started with the base, crosslapping the parts at the center. When I had a perfect fit, I drew the curved ends of the pieces, cut them on the bandsaw, and sanded them smooth. Also, I routed a relief on the bottoms that created four feet.

At the drill press, I drilled a hole near each end of the crosspieces and a fifth hole in the center. Next, I chiseled around the holes to make four through-mortises, leaving the center hole round to accommodate the brass tubing that holds the wire. Finally, I glued and clamped the lap joint.

The four posts are easy to make. I tackled the tenons on the bottom ends first, then on the top end, I made a centered slot to form the inside of the bridle joint.

Top pieces get crosslaps and tenons

The top is similar to the bottom, two pieces crosslapped in the center, but you don’t have to cut through-mortises for the posts. Instead, cut a tenon on the ends of each piece, which forms the center of the bridle joint.

Video

Classic Woodworking: Build a Contemporary Table Lamp

From Fine Woodworking #222

To view the entire article, please click the View PDF button below.

Fine Woodworking Recommended Products

Suizan Japanese Pull Saw

Comments

I'm trying to make this lamp now. Many of the dimensions are wrong in the pdf. Not a good set of plans. Very disappointed.

To "user-7161598", I saw your comment and decided to see for myself. I made a SketchUp model following exactly the dimensions provided in the article and found no errors. What dimensions did you find that are incorrect?

I just built a couple of these as Christmas gifts. The only dimension that I saw that was wrong the distance from the base to the first-inner-ring. The article says 4-7/8". I believe the correct dimension is 5 - 5/16".

One note on veneer. On one lamp I the veneer had figured grain. My thought was that it would make the lamp more interesting. It did, but it also makes the rings tend to warp and not be round. It takes some work (and practice) to get those rings into place. On my second lamp I chose some straight-grained veneer and the rings are very round and were easy to get into place. The straight-grained maple veneer looks good to, so I didn't loose much on appearance and was much less frustrated!

Hi

How thick is veneer?

Thank you

Would like to know the thickness of the veneer used in this project.

Did you read the article? The first paragraph says it's standard commercial veneer. Another place in the article he mentions that paper-backed veneer can work well.

Dave, I did read the article however neither of those terms have a consistent value for thickness. Commercial veneer is available in multiple thicknesses and there are several mil sizes available for paper backed veneers.

Not finding the 2-1/4'' wide wood banding nonglued required for this project. Of the 3 suppliers listed in the pdf the 1st doesn't carry it, the 2nd does not seem to exist anymore and the 3rd only supplies to CA.

Anyone figured out where to get veneer that works for this project?

Post-edit: I found this that may work and it is only 10 mil thick --> https://www.amazon.com/gp/product/B009KN8RDK/ref=ox_sc_act_title_1?smid=A1WUT0GFUE3HL6&psc=1

Does anyone know the ideal wood for the frame of this lamp? I see they list the best wood species for veneers, but I'm not sure about the frame. Any help would be greatly appreciated!

Log in or create an account to post a comment.

Sign up Log in