Hot-rod an inexpensive honing guide

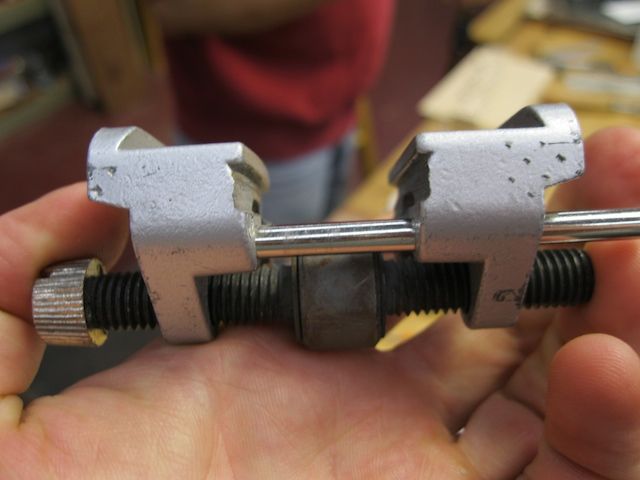

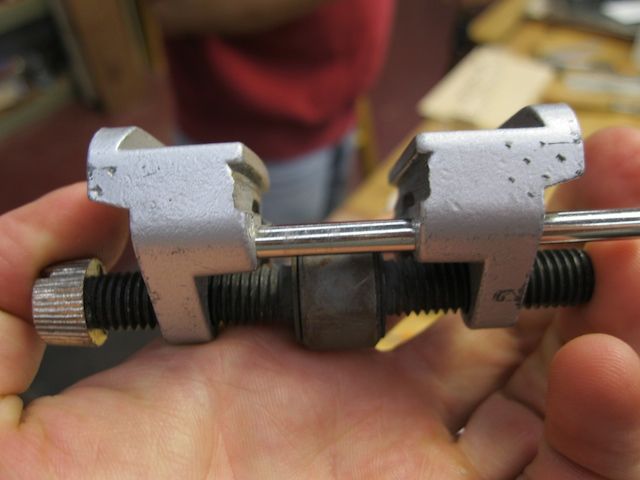

The inside "V" notches of a honing guide can be reshaped to accomodate different blades. In this case, it has been trimmed to hold shoulder plane blades.

Woodworkers love techniqes that work well, and won’t bust the bank. When it comes to sharpening and honing edge tools like plane blades and chisels, there are a lot of options–and some of them quite expensive. As a cost-conscious newbie, I have been using a side-clamping honing guide (about $10) paired with a projection jig made of scrap wood to set different angles and bevels. It’s a tried-and-true method that lots of experts advocate.

At a recent seminar on sharpening, Bob Van Dyke at the Connecticut Valley School of Woodworking showed a great quick trick for improving the quality of edges honed from a guide: Use a file to remove some of the material from the top face of the guide. The goal is to remove any convexity in the surface left by the manufacturing process. By evening it–or making it even slightly concave–the plane blades sit flatter against the surface, and the resulting honed edge is straighter–a key to effective sharpening.

I had to try it. It took only a few minutes, and seemed to work well.

It’s pretty simple to do: Set the guide in a vise and file away the top. Be careful not to remove any material from the sides. I stayed about 1/8 in. away from either side. Use your thumb to keep even pressure over the center of the guide, and work from side to side. I filed enough so that the surface felt even to the touch, with no noticeable ridge in the middle. But even if you go down a little far, it’s OK–the pressure of the sides should still hold the plane flat against the slightly concave surface.

This same technique can be adapted to help make honing guides for specific tools. For instance, Van Dyke reshaped the “V” notch in one guide so that it would hold shoulder plane blades better. Since honing guides are so in expensive, it’s a great way to make custom sharpening accessories. The notches can also be reshaped to hold chisels a little better.

Van Dyke uses a file made for aluminum to do the reshaping. In my own shop I’ll probably use a regular mill bastard file, and wipe chalk on the faces to prevent the aluminum from gumming up.

Comments

Thanks for showing this Ken,(and Bob also)I would never have thought about it myself,but once you see it, "DOH!"

Log in or create an account to post a comment.

Sign up Log in