I surfaced the first side with a number 5 Stanely Bedrock hand plane and a number 7 jointer plane. It was quicker than I expected. That said, this is nothing more than a small pine board.

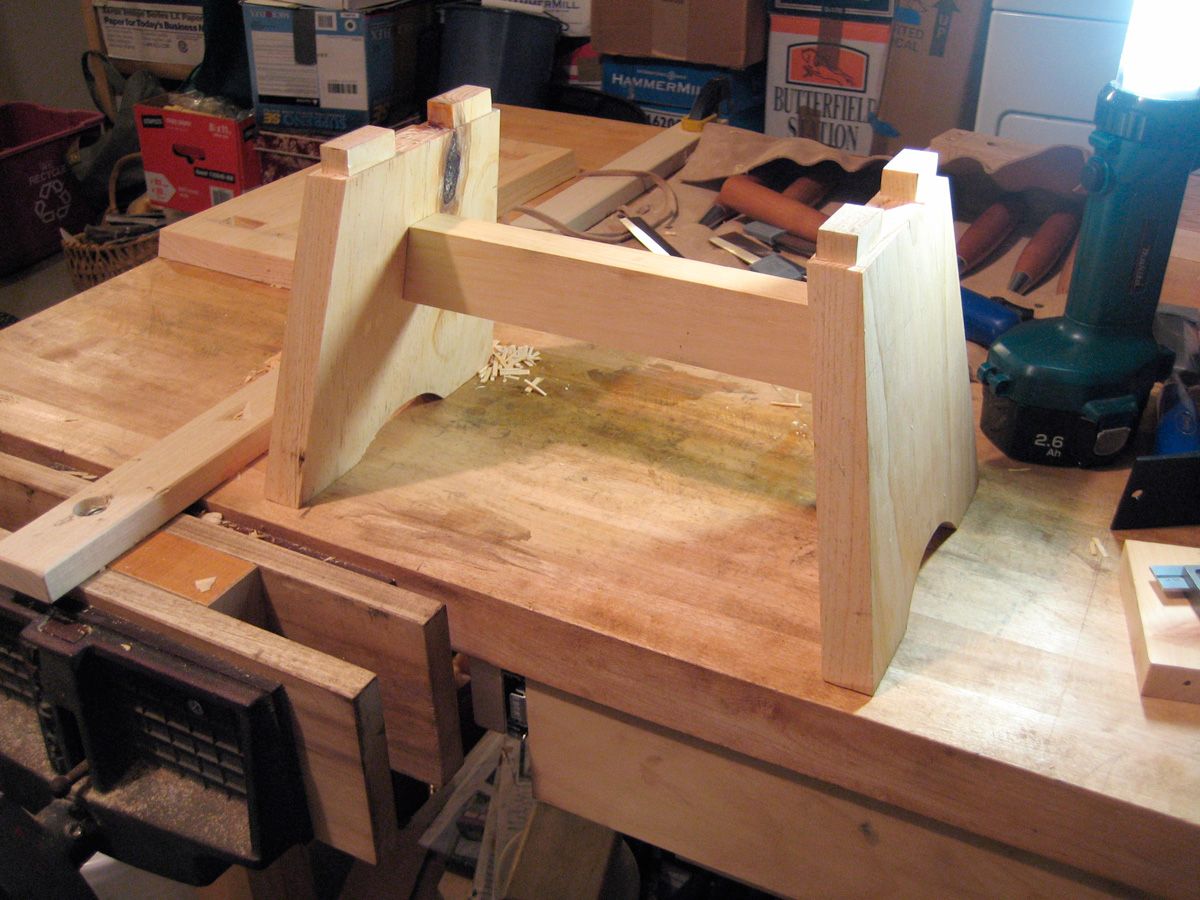

I built this small stool for my daughter over a weekend. She was continuously standing on a small decorative box that she would push to the window to look out. It seemed appropriate to build her a small stool as a replacement, and besides, I wanted to spend some time in the shop creating something. I certainly don’t have time for a highboy these days!. Or a lowboy for that matter.

I had a small rough pine board that was about 3 feet long by 8 inches wide and 1 inch thick. Not having a mechanical jointer and planer at home, I made use of my antique handplanes and became my own apprentice flattening this one board. With the blades all honed sharp, I surfaced one face flat, and then the other. All in all it didn’t take as long as I had initially expected it to. About 5 minutes for the first face and maybe 10 to 15 on the reverse face.

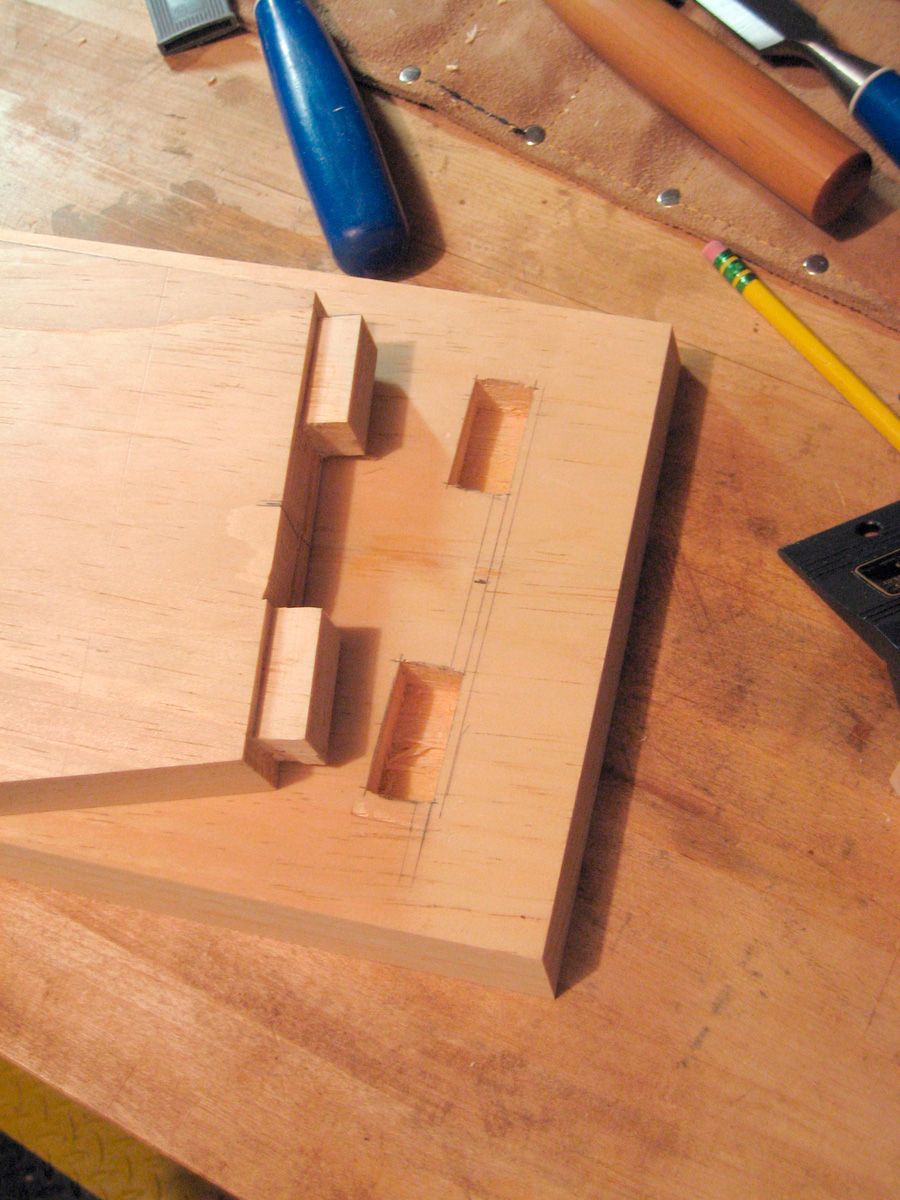

I was designing this stool on the fly, with whatever tools I had at hand. I have a small arsenal of the typical hand tools most woodworkers own: a few hand planes, some chisels and one dovetail saw. My only machine at home is a tablesaw, and I utilized it as much as I could. I cut the three main parts from a single board. I cut the top from the middle of the board and the two legs came from each end. I used a second small board for a connecting stretcher between the legs and used mortise-and-tenon joinery throughout.

In a few hours I had all the parts milled flat and cut to size. I hammered the mortises out using two different sized chisels and cut the tenons with the dovetail saw. A bit of chisel work was used to clear out the waste between the tenons. It took about 5 hours to build this small stool and maybe another hour or two for a quick sanding and application of shellac.

My daughter was quite happy with her new stool. When I presented it to her I expected her to either stand on it and look out the window or use it as a seat. But she proceeded to pick it up and carry it around the living room with her short pudgy arms wrapped around the top. Oh well. We all have our own ideas, even at this young of an age. She seems to like it and has had the opportunity to fall off it many times now. Nearly as many times as she trips over her own two little feet.

Comments

This reminds me of when I built something similar for my toddler. I built it out of plywood whivh I planned to cover with plastic laminate.

Before laminating I took the stool inside to "test" it. Becca loved it. She could wash her hands on her own!

When I took it back to the shop to finish it off there was a scene. I had to wait until she went to bed before I could take it back.

The next thing that little girl needs is a little table where she can crayon, build with bricks etc. 27 years later my eldest still appreciates the fact that I made her one.

I'm sure your family will enjoy that for years to come. My grandfather made me a wooden green truck when I was small. The durable toy survived my childhood and now it's in my son's toy chest.

Good job,I have a 1 year old sister(I'm 14)and she some likes to sit on my workbench or on the floor to watch me in my shop, seems like a great project for her

Log in or create an account to post a comment.

Sign up Log in