Table Saws Under Siege

U.S. government considers flesh-sending technology for all tablesaws, but is that feasible?

The tablesaw is a cornerstone tool in the majority of home and pro shops, and for good reason. Its versatility is unmatched—it rips and crosscuts, it cuts tapers and bevels, and it handles a number of essential joinery jobs, from dadoes to tenons. But the saw has a built-in risk: an exposed blade that spins at around 4,000 rpm.

There’s no license required for using a tablesaw, but with a bit of know-how and attentiveness, and some kind of splitter behind the blade, the tool can be used safely. However, the number of tablesaw accidents is staggering, averaging 36,400 a year (from 2001 to 2008), according to statistics compiled by the Consumer Product Safety Commission (CPSC).

Those numbers, combined with the estimated cost of treatment for those injuries reaching into the billions per year, have compelled the CPSC to consider making radical changes to tablesaw safety rules. The most controversial is the possible mandatory inclusion of flesh-sensing technology—like that developed by Saw-Stop—that will halt the blade upon or before contact.

The clock is ticking. On Oct. 5, 2011, after years of research, the CPSC issued an advance notice of proposed rulemaking (ANPR), giving the public 60 days to comment about whether new safety standards are needed and whether they should be mandatory or voluntary. If made mandatory, such a ruling will have huge consequences on makers of tablesaws, especially those whose bread and butter are lightweight benchtop saws common on construction sites. The Power Tool Institute (PTI), a trade association of U.S. portable and stationary power tool manufacturers whose members account for about 85% of all tablesaws sold in the United States, said the cost of compliance with that ruling could eliminate portable tablesaws from the market. A benchtop saw with flesh-sensing, blade-braking technology has not been proven in the marketplace, though SawStop has built a prototype and says that a production model will be ready by next summer.

The ruling would not just affect benchtop saws. It would require entire tablesaw lines, including contractor and cabinet models, to have the technology, raisingprices on all saws. To avoid costly changes to the industry, and since SawStop saws already are available for people to choose, the PTI is urging the CPSC to make the standard voluntary.

So how did the CPSC and tablesaw manufacturers come to this crossroads? For the answers, we have to flip the calendar back more than 20 years.

|

1939: Unisaw sets the standard for American saws. Introduced in 1939, 39he Delta Unisaw features a blade guard and splitter by 1949, as shown in this catalog image. |

|

1971: U.S. safety mandate. The UL issues a mandate (UL 987) on safety gear, adding antikickback pawls to the traditional gear—not much of an improvement. |

|

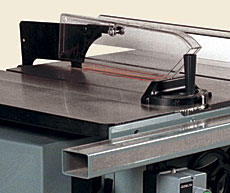

1996: Riving knives required in Europe. Common on European saws for decades, this effective anti-kickback device was not adopted by U.S. manufacturers. |

Spotlight on tablesaw injuries

The CPSC had been looking at the incidents of tablesaw injuries since the early 1990s. Alarmed by the numbers, the agency presented injury data to tablesaw manufacturers and Underwriters Laboratory (UL) in 1998, hoping they would update the voluntary safety standards (UL 987) to reduce the number of injuries.

At the time, the voluntary standard stated that all tablesaws should have a guard that consists of a hood that encloses the blade, a spreader, and some type of anti-kickback device, typically pawls. That outdated equipment had been on saws since those standards were written in the early 1970s and clearly it wasn’t working. You don’t have to be a Fine Woodworking editor to know that many woodworkers discarded those old, inconvenient systems, or that European saws had superior safety guards for years that included riving knives.

To respond to the CPSC concerns, the PTI implemented a training program, utilizing primarily videos distributed to shop classes and woodworking seminars about how to use tablesaws safely.

Enter the inventor

In 1999, Stephen Gass, a patent attorney and amateur woodworker, had an idea that could make tablesaws dramatically safer. Putting his doctorate in physics to work, he designed the SawStop device, which uses sophisticated electronics to sense contact with human flesh and then trigger a brake system that stops and retracts the blade fast enough to prevent an amputation or other catastrophic injury.

In June 2000, at a meeting with the CPSC, UL representatives agreed to look more closely at ways to improve tablesaw safety, according to CPSC documents. Later that summer, Gass and his partners, David Fanning and David Fulmer, unveiled the SawStop technology at IWF in Atlanta, demonstrating it on a hotdog. SawStop won the IWF Challengers Award, which recognizes companies that make significant advances in woodworking technology.

In October, Gass demonstrated a Saw-Stop prototype for Ryobi representatives in Anderson, S.C. He also gave Ryobi a prototype to test. Gass wasn’t interested in selling the technology to just one company.Instead, he was looking for a larger sales opportunity and to change the industry for the better, he said. “We did not want to see it on just one brand of saws,” he said, “and so we were unwilling to give an exclusive license to any one company. It was our feeling that this technology, like air bags, should be on every saw.”

In 2001, Gass sent the CPSC a prototype of the SawStop. After testing it, the CPSC awarded SawStop the Chairman’s Commendation for product safety.

While negotiations with Ryobi went on, Gass said he pitched his product to other tablesaw manufacturers, asking for what he considered a low 3% royalty at first, to help offset the additional costs of incorporating the technology. That royalty would increase if more tablesaw makers adopted SawStop (when market share reached 25% the royalty would go to 5%; 75% share would increase the royalty to 8%).

To avoid litigation, manufacturers believed they would have to equip every saw in their lines with the new technology, a process that would require redesigning the saws and retooling the factories where they’re made. And yet Gass’s invention hadn’t yet been proven to work in the real world. It was a tough decision.

In 2002, SawStop and Ryobi came close to a licensing agreement. However, the deal was never closed, and people involved in the negotiations differ as to why.

According to witnesses who testified in a recent legal case (Osorio vs. One World Technologies, Inc.), Ryobi chose to work with other members of the PTI on a joint venture to design a flesh-sensing alternative to SawStop, as well as a better guard system. David Peot, former director of advanced technology for Ryobi, testified that such cooperation among PTI members was unprecedented. “The people who belong to the Power Tool Institute are very fierce competitors. Never in my 30, 35 years of working with [them] had I ever been exposed to something where they said ‘let’s get together and develop something.’ ”

After the Ryobi deal fell through and with no responses from other tablesaw makers, Gass and his partners decided to develop their own brand. While they were working with designers on a saw, Gass and his partners petitioned the CPSC in 2003 to do something about the large number of tablesaw accidents that were occurring yearly, asking for a ruling that would require all tablesaws to have some sort of flesh-sensing technology and bladestopping device.

In 2004, SawStop rolled out its first saw. Then, in the spring of 2005, an accident on a Lexington, Mass., job site cracked open the floodgates on the tablesaw safety debate and its legal fallout.

|

2004: SawStop hits the market. After failing to come to terms with the existing manufacturers, Gass rolls out his own line of saws with his innovative safety device inside. |

|

2005: Riving knives become standard in the United States. The rest of the tablesaw industry, working with the UL, updates UL standard 987 to include riving knives as part of all guard systems. |

Osorio vs. One World Technologies

Carlos Osorio moved to Boston in 2003 from Colombia. Trained as a computer technician in his home country, he was unable to find similar work in the United States. On a recommendation from a friend, he took a job in April 2004 with P.T. Hardwood Flooring in Massachusetts, working as an installer and repairman. The 24-year-old had never been exposed to power tools until that job and was trained on the go.

A year later, on April 19, 2005, Osorio was using a Ryobi BTS 15 benchtop tablesaw to rip a piece of hardwood flooring to size. He testified that he was using the saw on the floor, that both the blade guard and fence were removed, and that he was making a tapered cut freehand. Clearly, he was using the tool improperly. Osorio also testified that he’d never seen a saw on the job that had the guard or fence in place.

As he fed the workpiece, it jammed and vibrated on the first try. He turned off the saw, cleaned sawdust and chips from the saw’s throat and top, and tried again. Like before, the workpiece started chattering, but instead of turning off the saw, Osorio pushed harder. Before he knew it, the workpiece had kicked back and his left hand had plunged into the blade.

Osorio endured multiple operations to repair his mangled hand and in 2006 his insurers filed a lawsuit on his behalf against The Home Depot, the seller of the saw, and One World Technologies, the parent company of Ryobi, to recover damages. In cases like this, the victim, or plaintiff, gets whatever money is left over after the insurance company gets reimbursed and all legal fees are paid.

When the suit finally reached the courts in February of 2010, the jury ruled in favor of Osorio, awarding $1.5 million in damages from Ryobi—The Home Depot was found not to be liable. Ryobi appealed, but the decision was upheld Oct. 5, 2011, the same date the ANPR was issued.

The jury ruled that Osorio was 35% at fault but that the tool he was using was unsafe because it didn’t have a flesh-sensing/blade-stopping device on it—technology that was available when the BTS 15 was made. As this issue goes to press, there are at least 50 other tablesaw lawsuits pending against various manufacturers. We’ve even seen an ad for a law firm saying, “Injured in a tablesaw accident? You may be entitled to compensation.”

|

2011: Controversial verdict. A Massachusetts jury awards $1.5 million in damages to a worker injured on a Ryobi tablesaw in 2005. |

Manufacturers weigh in

So why didn’t companies add SawStop in 2001/2002? The individual manufacturers I contacted were tight-lipped about it all, citing pending litigation. However, the PTI has a lot to say about the topic. Their first argument has to do with the injury statistics presented by the CPSC.

Do the numbers tell the whole story? The CPSC gets its data from its National Electronic Injury Surveillance System (NEISS), which collects patient information from NEISS-associated hospitals for each emergency visit from an injury related to consumer products. From this sample, the total number of product-related injuries is estimated.

According to NEISS data collected from 2001 to 2008, there were an average of 36,400 tablesaw injuries per year. In that same time period, the PTI claims, tablesaw sales had risen while the injury numbers remained relatively stable, meaning the number of injuries is actually declining.

The PTI said 800,000 saws have been sold since 2007 that meet the updated voluntary standard (UL 987), which includes an improved blade-guard design and riving knife. They point out that there have been no studies of that group of saws to determine the impact of the new guard system and any injuries associated with those new saws.

Will SawStop work in a benchtop tool? During the Osorio trial, witnesses for the defense claimed that SawStop would not work on a small benchtop saw. They cited structural issues with the tool, namely that the saw is too light to withstand the force of stopping the blade and bringing it below the table. Peter Domeny, a defense witness and the former director of safety for Bosch, who also served as a chairman of the PTI’s product liability committee, said adding SawStop would drastically change the size and engineering of a benchtop saw, making it heavier and less mobile.

Gass’s own testing at the time, however, indicated to him that the technology was “perfectly viable” in a benchtop saw. He now has a prototype built, ready for evaluation in the field. He said the production model will be unveiled this summer and estimates the cost of the saw to be under $1,000. A benchtop saw without SawStop runs from about $100 on the low end to $600 for a high-end machine.

|

2012?: Benchtop SawStop. Gass has long disputed claims that a durable, portable benchtop saw can’t be made with the Saw-Stop technology inside. Shown here is a prototype for a model he plans to have ready for production next summer. |

At what price, safety? One of the key arguments during the Osorio trial was the cost of putting the SawStop technology on a tablesaw. Gass and Domeny both testified that SawStop would add about $150 to the wholesale price of a saw.

That increase may be less painful with a cabinet saw that already retails in the $1,000 to $3,500 range. But raising the price becomes more of an obstacle with lessexpensive saws. With the retail price being two to two and a half times the wholesale price, said Domeny, the cost of a saw that used to be $179 (the price of Ryobi’s BTS 15) would jump to more than $500. That’s too much, said the PTI, for a tool that has a short life span (about six years, said the PTI) due to its exposure to the elements and transport from job site to job site.

The PTI claims that the cost of the replacement cartridge ($69) and blade ($50 to $100), which gets destroyed when the device fires, is prohibitive. They also say that Gass’ royalty fee “demands” are excessive.

Gass dismissed the arguments about increased manufacturing costs in an online Q&A with FWW editor Asa Christiana. “If tablesaw manufacturers had to pay for the injuries occurring on their products,” he said, “something like SawStop would have been incorporated on every saw long, long ago.”

Is SawStop a monopoly? Domeny revealed during the Osorio trial that engineers from Bosch had started working on their own flesh-sensing technology and blade-braking system back in 2002. “We were interested in a technology that can prevent the accident using similar principles,” he said, “but not to rely on a contact system, where you have to get injured in the first place before the system mitigates the degree of injury.”

Their system used a “pyrotechnic propellent” to bring the sawblade below the table in a flash but didn’t destroy the blade in the process. Domeny said the cost of a replacement propellent cartridge would be about $15. The project was handed over to the joint venture group of the PTI but was stopped because, the PTI said, “introducing this technology will result in costly patent infringement litigation (estimated to be at least $7–$10 million for each party) with uncertain outcomes.”

The PTI also said Gass has a monopoly on the flesh-sensing patent arena, claiming he owns 70 patents relating to the SawStop technology and that many are too broadly written. Gass admitted owning 70 patents, but he said, “I would guess that a little more than half our patents relate to the SawStop technology on tablesaws.”

The ball is in CPSC’s court

Now that the CPSC has issued its ANPR, the public has 60 days to send the organization comments and opinions about whether the flesh-sensing standard should be voluntary (added to UL 987) or mandatory. The CPSC says it will consider the economic impact of the ruling on the industry, and will not recommend one technology over another, though it remains to be seen if manufacturers will be able to meet the standard without violating Gass’s patents.

The PTI has made it clear how they will respond to the ANPR, encouraging the CPSC to “work with the power tool industry and others in the table saw community to promote safety through the voluntary standard process.”

Gass prefers a mandatory standard. Because the voluntary standards are written by manufacturers, he said during the Osorio trial, “it’s a completely perfect example of the fox guarding the henhouse. They write the standards and then they come to court and try to use them as a shield to protect themselves and say, ‘we met the standards.’”

FWW will also send a response to the CPSC. There are too many unresolved questions for us to take sides, but our editors and experts can shed valuable light on the real-world implications of tablesaw safety gear, including the new rivingknife systems. Then, like everyone else, we’ll wait for the ruling. We’ll update this story on FineWoodworking.com as it develops.

Fine Woodworking Recommended Products

Festool Cleantec CT 26 E HEPA Dust Extractor

Shop Fox W1826

Fein Turbo II HEPA Wet/Dry Dust Extractor

Log in or create an account to post a comment.

Sign up Log in