Ouch! The front apron of this desk now exhibits a strong glue line due to a dark-colored glue (Titebond III) having been used.

|

I generally keep two types of glue on-hand in my cubby here at Fine Woodworking: Titebond II (for general use), and water-resistant Titebond III, which I use for the assembly of humidors (I build a lot of them). Those of you familiar with these two products already know that the color of Titebond III is markedly different than it’s more conventional yellow wood glue brother. The water-resistant stuff is generally the color of my coffee (a light brown – I like milk and sugar). That brings me to the point of this post.

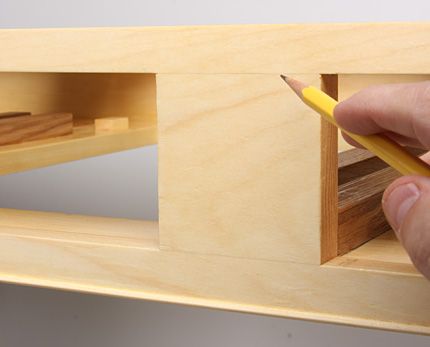

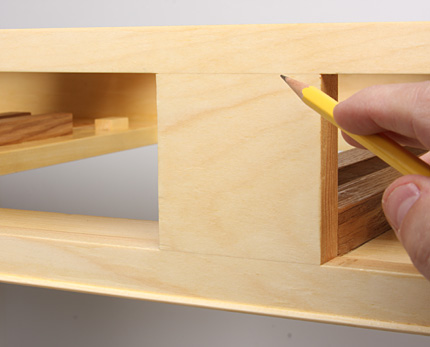

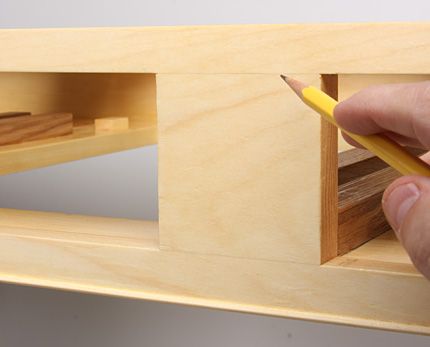

While working on my current furniture project, a simple Shaker-style writing desk, I wanted to cut the drawer fronts out of the same board I used for the front apron (a common method used to ensure the grain in your drawer fronts matches up perfectly to that of the front apron). As the glue-up commenced, I realized I had forgotten to snag my bottle of conventional yellow wood glue. “Not to worry,” I thought, “I’ve got a bottle of Titebond III right here on the shelf beside me.” Big mistake.

click to enlarge |

I proceeded to glue up the apron (minus the drawer fronts I had cut out) using the brown-colored water-resistant glue and ended up with a very subtle, yet incredibly annoying, glue line as a result. Now, I know it won’t bother my wife, or most anyone entering my home (except for the ocassional FWW editor popping by for a beer), but it will haunt me for the rest of my days.

Word to the wise: keep color in mind when you reach for that glue bottle! With any luck, my error will prevent you from making a silly mistake.

More on Glue-Ups Match Clamp Pressure to Wood Species Most woodworkers are underclamping. |

All About Assembly and Glue-Up Learn the basics of a top-notch glue-up. |

Gluing Up Tabletops Solid strategies for milling, matching, gluing, and clamping large panels. |

Comments

Don't worry, Ed, a couple of coats of black milk paint will cover that. ;-)

You're right - different glues can leave colored glue lines. However, there are 2 things you can do to avoid seeing your glue line that should be mentioned. First, you can use Elmer's white glue (the stuff kids use in school). It dries clear. Second, you can make the joint disappear entirely (no matter the glue used) if you clean up your long-grain glue surfaces with a pass from a sharp hand plane.

Good Tip,Thank you, this is something to plan for.

A couple of questions though...

1)is it possible this is brand specific, that other makers adhesives will perform differently where cured visibility is concerned, and

2) would glue line visibility have changed had you been working with a different species of wood?

All my work is done in the field, site made built-ins, prefinished cabinets and such, and I keep all three glues for specific purposes:

The Titebond III for gluing up dark prefinished moldings, the yellow for joints that will not be seen, and the Elmer's (that dries clear) for light woods or those prefinished light colors.

I agree that matching the color of the glue to the color of the wood is a wise step. I disagree that Titebond III is necessarily more water resistant than Titebond II. Both are very water resistant. For reasons irrelevant to 90% of woodworkers, the standardized tests in the USA for water resistance focus on the adhesive's resistance to hot, and even boiling water. While this may give hints at accelerated aging, the properties of most common glues change dramatically when you heat them above 150 degrees Fahrenheit. These tests tell us nothing about the value of the glue in the projects that most of us create.

Why should we care that Titebond III is more resistant to boiling water than Titebond II? Unless we are making cooking ware, we need a different test to compare the water resistance for projects and conditions that we care about. So far as I know, useful test results aren't available. Maybe Fine Woodworking can do some valid tests for us, comparing the strength and water resistance of different glues in the conditions that our woodworking projects normally face.

What is the shelf life of a opened bottle of glue? THis could change bulk buying practices if a gallon lasts far less time than it takes to use.

I dont know if I agree... I have been running the family custom woodworking business since I graduated from college in the mid 1990's. We have used almost every commercial wood gue available through suppliers here in Canada. I have my favourites, but when I started using Titebond III, I never looked back. Primarily, I think what makes it the best glue for me, is the viscosity (just right), the fact it can handle a few freeze/thaw cycles (very important for me here in Northern Canada), the working time, the fact it sands very well and desnt seem to clog up my expensive wide belt sander belts, and that is is brown. It is easy to see and remove before the finishing process - unlike many glues that dry clear, that you only see after the finishing process has begun.

I work primarily in hard and soft maple, white ash, red and white oak, but also walnut, cherry, alder, mahogany, etc. I find that with good, tight joints that come together without ANY gaps, even on white sap maple my glue lines are not visable (at least no more so than with another glue). Maybe it is that I tend to leave my panels oversize in thickness, and then take a finish cut with the planer? I dont know - but I do know that the brown colour of TIII hasnt caused me any negative issues.

Just my opinion, but if it matters, my opinion is based on using the stuff for 8-10 hours a day full time.

AJC

I do a lot of tables the way you do and always use Tite III I'm sitting at one right now and for the life of me I can't see the glue lines where I ripped the front apron at all. The table top was glued the same way and can't see it there either. The wood is cherry and the finish is Tried & True varnish / oil, four or five thin coats.

As for the waterproof part, I sometimes forget to wash out my brush, a good art brush I use for spreading glue, and the result the next day when I find it is one hard solid brush. Puting it in a glass of hot water and dish soap fixes that in a couple of hours. I think the brush is better for it.

Just my 2cents.

Hi swenson: Reason you can't see your glueline is due to the species of wood. The color of cherry is much closer - or complimentary - to that of the Titebond III. Doesn't matter how perfect a joint it is - this one was handplaned to a perfectly flat fit - that dark glue on such a bright white colored wood species 'll kill ya every time.

Best,

Ed

Like I said, I use a lot of hard maple (sap) and use TIII regularly. Here are two randon pieces I glued up a few days ago - personally I do not find the glue line obtrusive. I cannot really see much difference between a white pVA, yellow aliphatic and the TIII brown glue, in a tight fitting joint.

One side I machine sanded to 80 grit, one to 120 by hand. The grayer photo was taken with flash, the warmer two without.

[IMG]http://i83.photobucket.com/albums/j307/ajcoholic/IMG_0275.jpg[/IMG]

[IMG]http://i83.photobucket.com/albums/j307/ajcoholic/IMG_0269.jpg[/IMG]

[IMG]http://i83.photobucket.com/albums/j307/ajcoholic/IMG_0273.jpg[/IMG]

Log in or create an account to post a comment.

Sign up Log in