Delta’s New 14-in. Bandsaw has a European Flair

The new bandsaw has a European look and a large table.

It’s been just over a year since the sale of Delta was finalized. And after getting their South Carolina plant up to speed, and dealing with all the fussy business of the sale, Delta is beginning to roll out new tools.

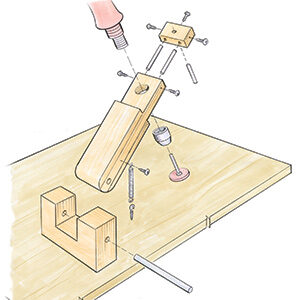

First off the line this year was a new cyclone dust collector and floor sweep vac accessory. But now they’re introducing a new 14 in. bandsaw (model #28-400), and you won’t recognize anything but the paint job.

Gone is the familiar cast-iron frame, replaced with a Euro-style steel frame with an open base. It features a 1 hp motor, with two speeds (1,620 and 3,340 fpm). The cast-iron table is large, 15 3/4 in. by 18 7/8 in., and accommodates Delta’s 12-in. and 24-in. fence systems (models 28-856 and 28-848, respectively). Its T-slot will also accept most standard miter gauges (3/4 in. by 3/8 in.).

It features roller guides top and bottom and has a cutting capacity of 13 5/8 in. to the left of the blade. Resaw capacity is 6 in., but Delta is working on a “deluxe” 14-in. saw that will have 12 in. of resaw capacity. That model, say Delta reps, should be out later this year.

The 28-400 bandsaw will be available in March, according to Delta reps, with an MSRP of $630.

Comments

Good to see the "new" Delta is willing to take a fresh design approach to the 'look' of its tools. Now the real challenge: Make them 'work' better.

Cast off the chains of traditional machine designs that carry forward the old basic machine layouts, templates and features we have seen since woodworking tools have been electrified. Seems like WMH, Delta, Grizzly, Makita, Ryobi, RIGID, etc., etc. are willing to put glitzy badges and sexy paint/colors on next year's designs, but they are not bringing design breakthroughs into the industry. Design breakthroughs such as:

User friendly, high accuracy features in the use of the tool. Easy to see digital measurement that is built into the design, not after market add-ons. Everything from table-saw blade angles, and blade height, to spindle heights on planers, jointers, router lifts.

Most tools with a spindle do not have true variable speed, nor digital RPM meters like the Powermatic drill press.

Power feeds on the adjustments that today require poorly placed cranks and handles to manually manipulate gears/racks/pinions/. Maintain the hand cranks for fine adjustments, but get rid of the poor placements and poorly operating hand-crank mechanisms that have been around for a hundred years. Go high-quality, back-lit digital, not verniers.

Flesh sensing safety features on the order of SawStop. Time is long overdue to stop the foot dragging, whimpering and whining on this one!

A lot of these are examples that most folks would recognize in the machine tool industry from the 1970's, and earlier.

Seems that there is almost no true engineering going on in the big tool companies. When you look at next year's catalog, 95% of the tools will look just like they did 10 years ago. Come on folks, bring some genuine innovations in quality, useability and design back to the pride we used to feel in "Made in the USA". Do some engineering! It's way overdue!

There is a huge worldwide market that will pay a premium for these innovations. You'll be surprised how many home workshops will gladly pay the premium.

I sort of like my old early 80’s work horse (made in USA) with the riser block and all the modifications I’ve made to make it perform as needed. I certainly would not replace it with a new Delta 14”.

I have just looked at the new delta 28-400 at my tool supplier, Wellbeck Sawmill Limited. I am happy to see that they replaced the earlier version of the delta band saw with this one, and they kept the same price,$600. It looks nice to me, big table, nicely placed vacuum port, bearing guides, but I do have a concern about Hp of 1.

This may be a little skimpy.

Log in or create an account to post a comment.

Sign up Log in