Fine Furniture with Biscuit Joints

For much better results with biscuit joiners, anchor the tool, not the workpiece.

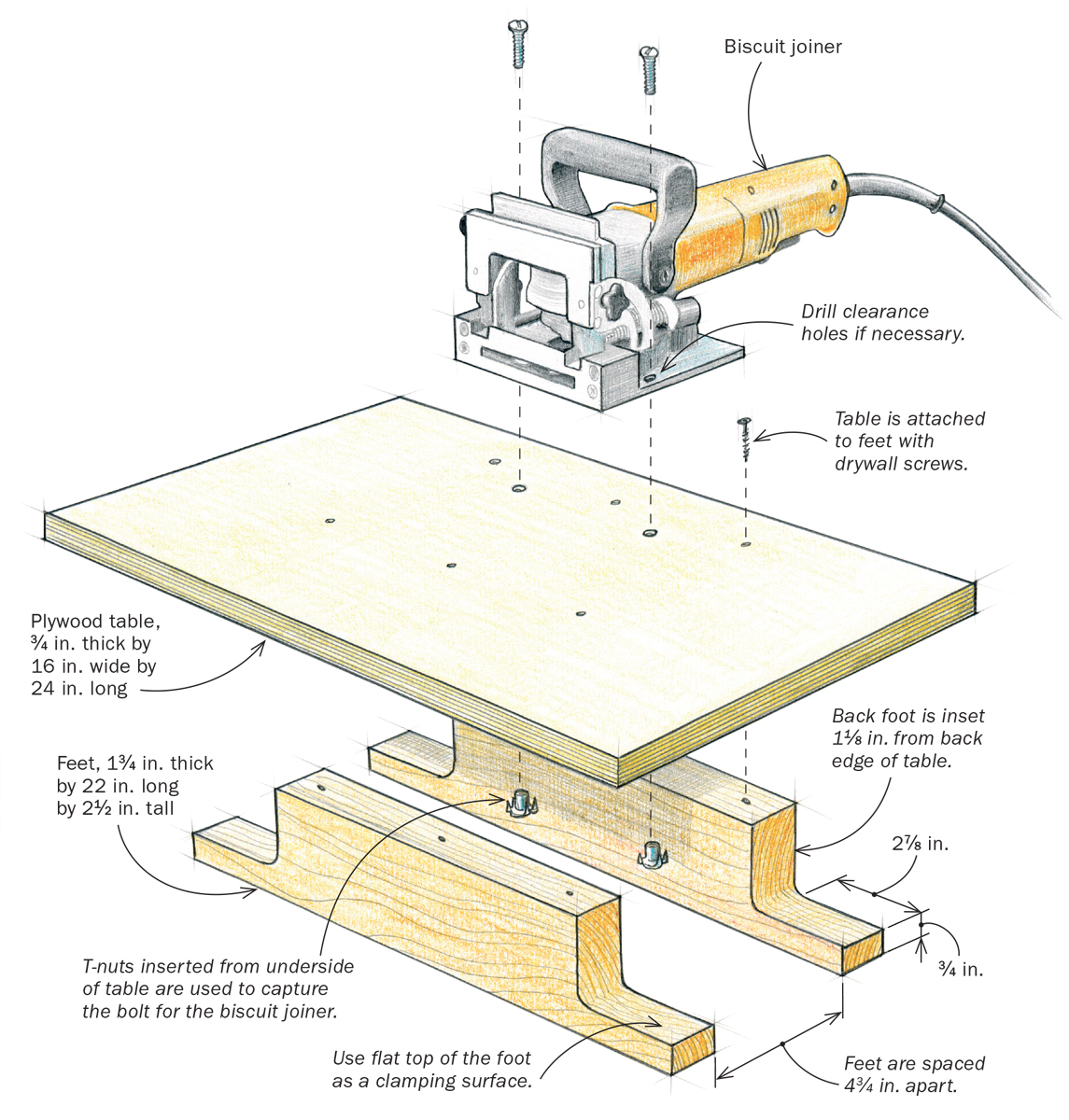

Synopsis: Are you biased against biscuits? It might be time to take another look. Michael Fortune has, and he’s learned that they are great for joining the rails and stiles of a face frame, attaching a solid-wood frame around a veneered panel, tabletop, or door, joining a leg to a veneered panel, and other uses. Biscuits also let him build adventurous furniture that would be difficult with traditional joinery. Wait, you argue: Biscuit joiners are inaccurate, they jerk sideways when you start a cut, and they jump around when you’re trying to use them. You need to try Fortune’s solution, and attach your joiner to a shopmade table. It might just change your attitude about biscuit joints.

If you ask a furniture maker about joinery for fine furniture, you’re sure to hear about dovetails, mortises, tenons, dadoes, and even rabbets. But I’d be surprised if biscuits were mentioned, unless only to explain how they have no place in high-end work. That’s a shame, because there are some joints where a biscuit is the best solution. They’re great for joining the rails and stiles of a face frame, attaching a solid-wood frame around a veneered panel, tabletop, or door, or joining a leg to a veneered panel. Biscuits also let me build more adventurous furniture that would be difficult with traditional joinery.

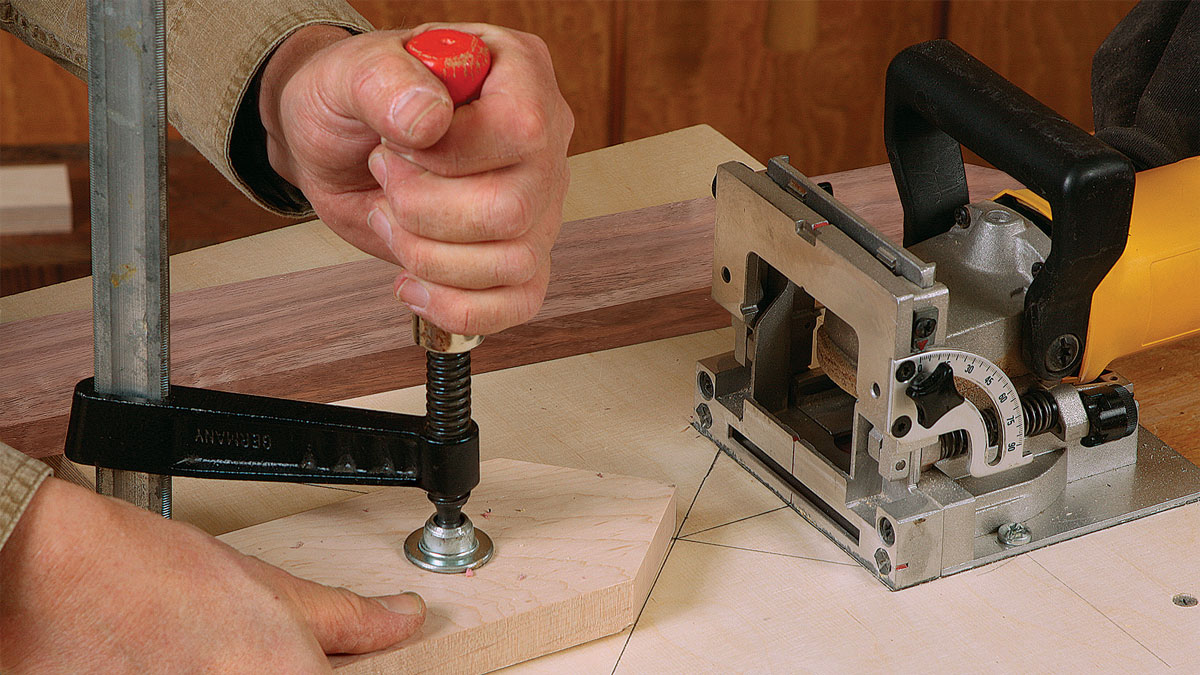

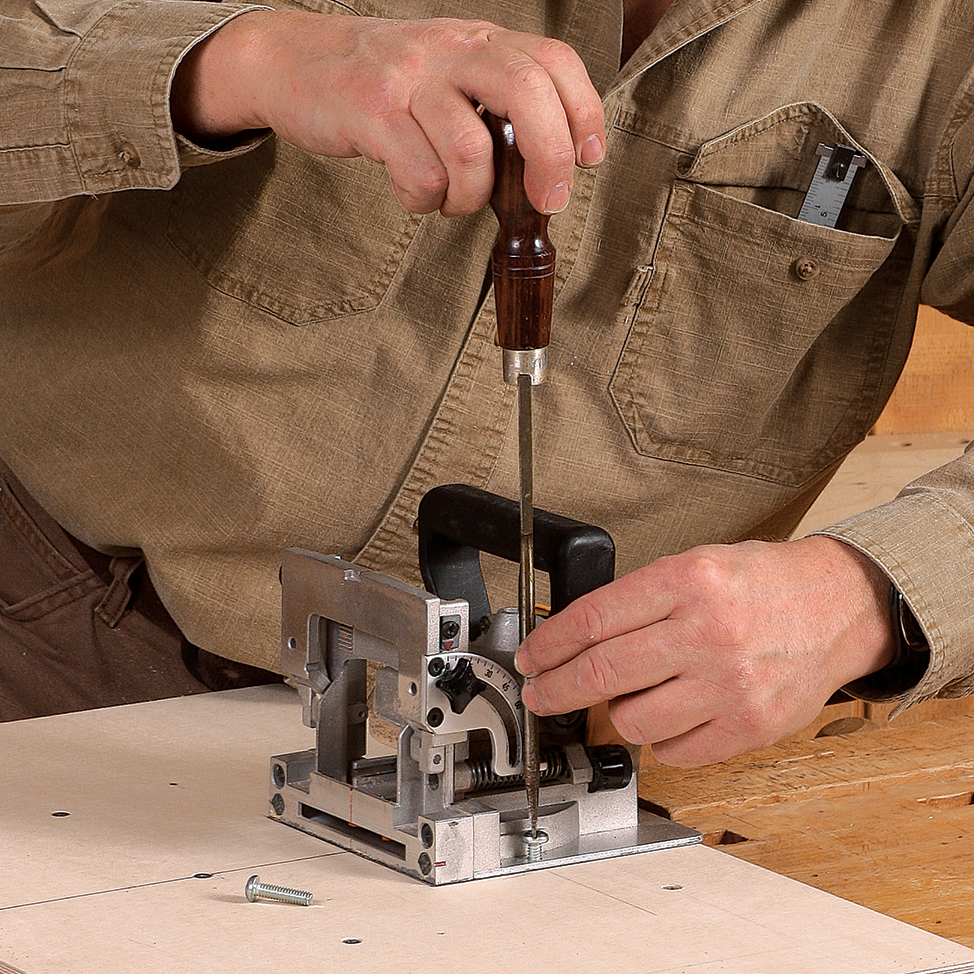

Perhaps the biggest reason why biscuits have been dismissed by many furniture makers is that biscuit joiners seem incapable of accuracy. The cutter’s rotation has a tendency to jerk the machine sideways when you start the cut. Also, biscuit joiners can be difficult to hold and they have small fences, so they jump around and lift off the work. However, I’ve found a great solution to all of these problems: Turn your biscuit joiner into a stationary tool by attaching it to a shopmade table.

Attached to the table, the biscuit joiner really does have a place in fine furniture. I’ll show you where it’s smart to use one and how to get the best results.

When and where to use biscuits

Biscuits can be used to join two solid-wood parts, two veneered panels, and solid wood to a veneered panel. But they can’t be used everywhere. Don’t use them for heavily stressed joints, like those in a chair, or for joints that hold a lot of weight, like those attaching shelves to a bookcase.

OK, that covers where to use them, but not how. A strong biscuit joint is a balancing act. You need enough biscuits to create adequate glue surface, but not so many that their slots significantly weaken the two parts you’re joining. I follow these guidelines to determine how many biscuits a joint can handle and where to put them: First, biscuits should be at least 3 ⁄16 in. from the top surface and 1 ⁄8 in. above the bottom one. Second, slots should be at least 1 ⁄4 in. away from any edge—any closer and the remaining material is too weak. Likewise, the minimum spacing between slots is 1 ⁄4 in., but I typically space them 2 in. to 3 in. apart.

Finally, go easy on the glue and apply it only to the slots (spreading it around) and, of course, the mating edges of the parts. Then wait at least 24 hours after glue-up before you sand or plane the parts. Biscuits are compressed during manufacture, and water in the glue causes them to expand and push out on the material surrounding the slot. That creates a slight bump on the surface.

From Fine Woodworking #227

For the full article, download the PDF below:

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

Veritas Precision Square

Leigh D4R Pro

Comments

Really good article; I've never seen anyone clamp down the biscuit joiner, but it seems like a really good idea. One thing Michael didn't mention when outlining best uses of a biscuit joiner — the one it seems designed for — is edge-gluing boards to make wide panels. This has saved me endless time in the shop, since it's a great solution to align boards simultaneously and yields a perfectly coplanar surface.

Log in or create an account to post a comment.

Sign up Log in