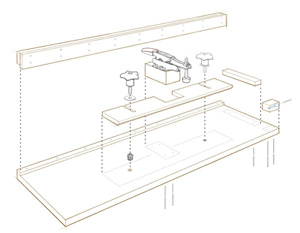

See it in Motion: Table Saw Leg Tapering Jig

![]() Use the See it in Motion QR codes in Fine Woodworking magazine to access a variety of short video clips that will help you better understand the jigs, tips, and techniques our authors use in every issue. Just download a QR Reader app on your smart phone and use it to scan the See it in Motion code icons found in the magazine.

Use the See it in Motion QR codes in Fine Woodworking magazine to access a variety of short video clips that will help you better understand the jigs, tips, and techniques our authors use in every issue. Just download a QR Reader app on your smart phone and use it to scan the See it in Motion code icons found in the magazine.

Modified Circle-Cutting Jig for Curved Parts

In Fine Woodworking #229, furniture maker Steve Latta explains how to construct a safer, more effective leg tapering jig for the tablesaw. While most tablesaw sleds and jigs rely on the miter gauge slots to guide them, Latta’s rides along a rail which is clamped to the saw’s rip fence. In this way, the user is able to back the sled out of the cut after each pass, without the sled falling off the end of the saw table while rotating the leg. Latta’s sled uses a fully adjustable fence to locate the leg in relation to the blade’s path of travel, and a simple toggle clamp holds the workpiece firmly into place. You can see the jig in action in the video above, and learn how to build and use it in his article, Perfect Tapers on the Tablesaw.

In Fine Woodworking #229, furniture maker Steve Latta explains how to construct a safer, more effective leg tapering jig for the tablesaw. While most tablesaw sleds and jigs rely on the miter gauge slots to guide them, Latta’s rides along a rail which is clamped to the saw’s rip fence. In this way, the user is able to back the sled out of the cut after each pass, without the sled falling off the end of the saw table while rotating the leg. Latta’s sled uses a fully adjustable fence to locate the leg in relation to the blade’s path of travel, and a simple toggle clamp holds the workpiece firmly into place. You can see the jig in action in the video above, and learn how to build and use it in his article, Perfect Tapers on the Tablesaw.

Comments

Why is it that I cannot see the video on chamfering proud? Each time I click on it the leg tapering video comes up.

For those of you who have not tried this jig it is SIMPLE and SAFE. A biginner can use this.

I must be missing something. It's a one hour project, but I am on my third day, with two trips to my local Woodcraft and a telephone call to Bessey Tools, North America.

First, what size legs is it designed to taper? What angled tapers are possible? No information is given. I assumed that since none were given, it was universal for relatively standard sized furniture legs. That is not the case. After I got ½ done it became apparent, the fixture will not work as shown in the article for either the size leg or the angle of the taper for which I embarked upon the project.

No instructions or dimensions are given for the key elements of the fixture – the location of the threaded inserts and the slot for slot for the fence. How far forward or back should the fence be placed? On what is its location dependent? Those obviously effect the size of the piece that can be tapered.

Likewise, the stated thickness of the hardwood platform on which the Bessey Adjustable Clamp sits dictates that the piece to be tapered be at least 1-5/8” thick if a standard Bessey Adjustable Toggle Clamp as shown is used. That is not stated – so that if one is to taper something of a different dimension, one would have to try to replace the hardwood platform, or replace the whole fixture.

It should also be noted that Mark Shofield’s video shows a Bessey Clamp that is not commercially available. See the elevation of the clamping pad below its base at 29 seconds into the video.

Mark states that because the clamp is adjustable, he does not have to use the cut-offs from the first two sides of the legs to do the third and fourth. That is not correct for an off-the-shelf Bessey adjustable clamp – and he does not state how he has modified it. Bessey adjustable clamps do not clamp material below their base elevation. Mark has (best guest of the Bessey Representative with whom we spoke) taken the bolt and hold down pad from the high profile self-adjusting clamp and used it on the low profile clamp.

Bessey does not sell different length bolts and pads separately commercially.

I don’t know if knot2serious will come back and read this but hopefully he’s found the article that’s linked in the text above. Gives you all the info you need to build this jig.

For years I’ve used Norm’s taper jig, but it wasn’t all that satisfying to use. Functional, reasonably safe, but not what I would call precise. I’m gonna try Latta’s jig since he’s taught me so much about stringing, and is all about safety. I want to keep all my fingers!

ChipSawdust - I just built this jig and I followed the information in the article linked in the text as you referenced. That article does not provide sufficient information to accurately build the jig. Knot2Series makes several good points. I had to visually interpolate many key dimensions to properly place the threaded inserts, locate the adjustable fence to allow for different thicknesses of stock, and adjust the height and location of the toggle clamp support block. Having to make all of these guesses and adjustments is quite contrary to Latta's statement that 'construction is straightforward'. What I ended up with will probably work for tapering legs of a certain dimension, but not all. I can see having to modify it for legs having dimensions which fall outside of this jig's capacity. I think Steve Latta could have been a bit more specific in the article about its use and limitations.

Log in or create an account to post a comment.

Sign up Log in