What time is it? Time to watch what you're doing...

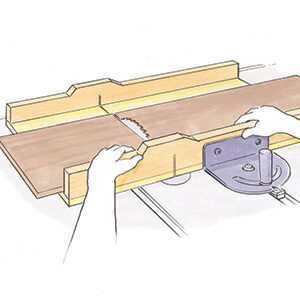

In this morning’s in-box, I found a note from reader Rick Williams of Tuscon, who included this photo. Rick said he had his aftermarket miter gauge set to cut at 45 degrees, but forgot to readjust the gauge’s aluminum fence, leaving it in the blade’s path.

“Unlike the operator, the blade stopped at exactly the right time,” Rick wrote. “Nothing got hurt except my pocketbook.”

Rick says it’s now the most expensive clock he owns, but who knows – if he checks it often enough, it might just pay for itself.

How do you remind yourself to stay safe in your shop?

Comments

Every time I use the saw, I first inventory all ten of my fingers to remind me to keep them where they are. So far it's worked!

I've got two of those! One for an expensive crosscut blade, the other for a very expensive dado set. But no clock movements.

Good idea.

I have a modular set of mental "film clips" for various sharp things spinning at high speed, with and without proper hand placement and pusher blocks. Those without proper hand placement or appropriate pusher blocks all end with a red substance splattering the lens, which acts as a motivational factor.

In other words, I try to think about the operation at the macro level, and what might go wrong, before carrying through.

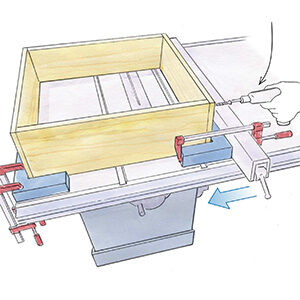

I moved my all metal Incra miter gauge from my Delta Table saw, where I do dadoes and rabbits, to my Saw Stop and forgot to readjust the Incra's fence. I ran the Incra into the blade and WHAM there went $200 (WWII blade and a new cartridge.) The blade made only the tiniest nick in the Incra's fence. Pretty remarkable to my mind.

Count me in with my colleagues as I have a similar trophy on my wall and made the same mistake with my Incra fence. Regardless I remain strongly in favor of SawStop and have changed my operating procedure to have a push through of my miter gauge whenever I use it prior to turning on the saw.

Ralph, I've got those mental film clips too. I usually play them long enough to make myself shudder, and then I'm good. John, I'm adding your suggestion to my pre-flight checklist for the miter gauge. Terrific idea. Thanks to both of you!

I'm not sure how running a miter fence into the blade is a proxy for losing ones fingers-- but I suppose it helps when rationalizing the loss of a $100 blade and $50 cartridge. And it helps sawstop marketing. But its sort of like a car whose wheels explode when you are about to hit another car pulling into a parking space.

Sawstop is a start-- but we need better solutions. We need some of the computer geniuses spending all their time and imaginaton on the next new angry birds app to focus on solving this very real problem. We need fine woodworking to seek out and spotlight other safety technology. How about a sponsoring a prize to the inventor of a brake that doesn't break the blade.

All I have to do to stay safe is look at my left thumb. In 1984 I reached behind the blade to hold down a chattering thin rip and in a split second lost the last 1/2" of it. It is a vivid reminder for me and others I teach. I've never seen saw stop test that one.

Rule #1 - SLOW DOWN!

The first step to an accident is to be in a hurry.

Rule #2 - Respect the tool.

Whether it is a power or hand tool, they can all hurt you if you aren't careful

Rule #3 - Safety checklist.

If you've ever been in the military, then you know they have a checklist for everything. Develop either a mental one for each tool, or even better, write it down and post it at the tool. Just seeing it will remind you of rule #1 and maybe make you pause before you screw up. Mark dangerous areas with red or yellow, if possible, to remind you to keep fingers and hands away.

Rule #4 - Learn from others.

Push sticks, push pads, hold downs, ear/eye protection and other safety accessories exist because of other's mistakes. Use them.

Rule #5 - Use your brain.

If it looks dangerous, it probably is. Find a different way to do it. If you can't figure out a different way then ask someone else. Don't take the chance. It isn't worth the risk.

Now I'm going to print this out and post it in my shop since I'm not as good at following my own advice as I am in giving it.

I am using more hand tools these days and the benefits are three fold. One, I'm around less dangerous tooling - reducing the probability of injury. Two, when I do use my TS and router I am more safety conscious due to less chance of mistakes from repetition and monotony. Three, I tend to become more of a "thinking" woodworker using hand tools. There's more planning involved and my actions seem more methodical. Rushing definately does no good in the shop.

I, too, have a brake induced blade trap caused by my metal crosscut gauge. But what caught my attention was the thin-kerf blade that got caught in yours. Check your sawstop manual. Thin kerf blades are not compatible with their riving knives. I'm surprised the combination was working for you.

First off- WHY IS EVERYONE SO INTERESTED IN "IDIOTPROOFING" the idiot..... THERE IS NOT NOW AND THERE NEVER HAS BEEN SUCH A THING AS AN "ACCIDENT" IN A WOODWORKING SHOP......You get eaten by one of your tools, you did something STUPID !!!!!!!! None of your tools are dangerous........................Until you walk through the door..... Still safe aren't you????? Ah ah, don't touch that switch just yet....Not 'til you realize that the most dangerous part of those whirling noisy machines is not mounted on the machine, but on the end of your hand!!!!!!!!!!!

Oh, BTW, my thumb on my left hand is 3/8inch shorter after encountering a 3 knife jointer spinning about 2800 rpm... It went so fast and slick that I never felt it and didn't realize I was hurt til I saw the blood..... Doctor said it was the most beautiful woodworking "stupid stunt" wound she had ever seen...

This happened 25 years ago- I am 78 now, and wouldn't have a Sawstop if it was given to me. Tired of being protected from myself by over regulating my world... If Incra fences trigger it, how about a loose knot???? And I have problems with right tilting blades- another idiotic import from Europe- along with European cars...........

So, usafchief, are you saying that if a machine had existed that would have prevented the loss of part of your thumb, you wouldn't have wanted it? Are you saying that you were an idiot and deserved to have an accident?

Isn't it better if there are safety features on machines that help protect us from our all-to-human momentary lapses in attention or judgement?

Just trying to understand your point of view here.

USAcheif is %100 correct. The only safety device needed is that 3lb slab of mush sitting on top your neck. There is no such thing as a shop accident, a gun accident or a car accident. In every single case, at least one negligent human was involved. If you can take 5 minutes to sharpen your tools, you take 2 minutes to sharpen your brain and think through what you are doing. Cognitive ability is what separates us from the animals. It's time people start using their grey matter and stop relying on the nanny state to protect them from themselves. Safety devices like Saw Stop lowers a persons safety level by letting them depend on technology instead of intelligence to keep their digits in place.

There are some safety devices that we now take for granted that didn't exist 40 years ago: Anti-lock brakes, for example. Should they be outlawed on the grounds that only an idiot would slam on the brakes in slippery conditions, and that whatever happens as a result of that is just what the idiot deserves? And what if the idiot runs into somebody else because he couldn't stop?

Still trying to understand the position...

They have a clock like the one pictured at the Techshop where I'm a member. Pretty cool idea. Obviously, they also have a sawstop table saw in the shop, and I feel my safe judgement starts slacking since the saw will stop in time to prevent injury. What stops me from doing stupid things is the $200 charge the shop will charge me if I set off the brake, money I don't want to pay for a stupid mistake.

Pippy11, Sawstop did have a plastic brake that did not ruin the blade during the development years, but it didn't go into production. I think Steve Gass gets a kickback from the blade manufacturers every time a sawstop brake discharges.

As an ER doc I see a table saw injury about every two months,I'm buying a saw stop for the same reason I use seat belts and grounded plugs

I think that's great reminder to be safe when you are working. I'm sure that all of us try to work carefully, thinking about and planning what we are going to do and how to best and safely perform each task. Unfortunately, we are far from perfect, and mistakes can happen. I'm fortunate to have all parts of my 8 fingers (and two thumbs) but I've had a couple of scares.

My next tablesaw purchase will be a Sawstop, or something with similar technology (I have no immediate plans for such a purchase). It's worth paying more for the technology, in my opinion.

I don't believe that all tablesaws should be required to have the technology however, and I don't think that the Osorio lawsuit should have been allowed to go forward, much less gone to a verdict in favor of the plaintiff.

I laughed when I read this....I did something similar: Made a miter extension and the t-track was impreceptably close to the blade. I ran my first test and bang! The blade dropped below the surface of the table. It happen quicker than the eye could see.

My heart sank because I lost a very expensive blade that was just about brand new. On the other hand, It reinforces my decision to put safety first.

At the end of the day, I can buy a new blade, I can't buy a new hand. And its for this reason, I urge everyone to consider a SawStop. Oh, I should mention that the you don't trade accuracy and convenience for safety!

I keep my spent SawStop break on the wall as a reminder - accidents happen at lightning speed - the more time in front of a table saw, the greater your chances of having a problem.

Sounds like you sacrificed an expensive blade and cartridge to save a less expensive miter gauge. I didn't read anything about a finger coming into contact with the blade. How is that saving you pain or money?

Wow. It's amazing the level of hostility to sawstop by some on this thread.

Anybody who works with anything dangerous, tools, gas, electricity, guns, etc. become so accustomed to their dangerous nature they get too comfortable with it. This is nothing new. Most, if not all of us, are aware of that phenomenon.

ln my shop I will often crank the blade up on my table saw and turn it on, and looking at, it remind myself how powerful and dangerous these tools are.

quote baudi:baudi writes: So, usafchief, are you saying that if a machine had existed that would have prevented the loss of part of your thumb, you wouldn't have wanted it? Are you saying that you were an idiot and deserved to have an accident?

Isn't it better if there are safety features on machines that help protect us from our all-to-human momentary lapses in attention or judgement?

Just trying to understand your point of view here.

Posted: 11:29 am on October 6th. I don't make a practice of being an idiot................ But in this case I was one.... The jointer guard was in place.. I was truing up a 4" wide board prior to running it through the planner.... It started to chatter with about 6 inches left....Instead of reaching about a foot for my special jointer push block, I laid my hand down on the board and continued to feed, it continued to chatter, my thumb vibrated off the end of the board getting kissed by the hungry jointer...The jointer guard was in place, the special push block was removed from its storage spot and setting within a foot of my hand....I didn't use it... Plain and simple, I committed an act of stupidity and in doing so, I guess that I had your definition of an "ACCIDENT"..... My point of view: all table saws for the past 50 years have come with at least 2 safety features; a blade guard and a riving knife, and some have a "Bump or Knee" switch.... I like perhaps 75% of us had removed both of these as they got in the way for some operations and were too much trouble to put back on.... About 25 years ago, I made a counterbalanced one that could be swung out of the way when dadoing or making molding and swung back for other operations. As for the guys who cut their Incra devices, was that an act of neglect (stupidity) for not making sure of where the blade was going to cut BEFORE you turned the switch on, or was it an accident...... It makes no difference what safety device is employed in any operation, if you don't have your head tuned to what you are doing, some one is going to get hurt, or precious material is going to get wasted.. Dependency on an expensive safety device will generate complacency and the other safety device will be removed for reasons I have stated...... BUT, I won't lose any digits because I have a 3200 dollar SawStop!!!!... If the inventor of this device was really interested in your safety, he would make the device available to other manufacturers with a licensing fee....... He is not, as evidenced by his efforts with Federal gov't......

My point of view is this: no "safety device" will ever be a satisfactory substitute for not using your brain..... My table saw is a 45 year old Craftsman bench saw (before they made contractors saws- a poor substitute)... Were I to have a choice between a PowerMatic or the SawStop, I would take the PowerMatic, even though it is probably made in China....

I still want to know how the SawStop would function if it hit a loose knot in oak or walnut?????? If 6061 aircraft aluminun can trip the mechanisim, who is to say that that loose knot won't wipe out a blade and a cartridge.... Still waiting for the first report of injury from someone reaching over the top or behind the blade on his SawStop and getting hurt because the age old blade guard has been discarded....BTW, today's auto brake system originated with aircrat- designed to prevent landing with the brakes on...The auto ABS is worthless on wet or icy pavement and you had better be ready to use the old fashioned system- if it was ever taught to you. The best and cheapest safety device to date is still between most people's ears- there is no substitute.....

The sawstop is not affected by a loose knot in a board. It's triggered by contact with something that conducts electricity, like a finger or a hotdog. It could be triggered by a very wet board, but it has an override switch for situations like that.

The guy who invented it did offer to license it to saw manufacturers, but they ignored him.

Yes, I know that anti-lock brakes don't work under all conditions. But they do work under many conditions that would otherwise lead to crashes. I'm still not sure what your position is: all safety devices are bad under all circumstances, and so they shouldn't be installed?

Nobody is saying that the use of a safety device means you don't have to think about safety. It's just one more safety net in case something bad happens. Since you were in the air force, you know that flying relies on backups to backups to backups so that if one thing goes wrong, it doesn't necessarily cause an accident.

I'm sorry you're so angry about so many things, usafchief. You must have had a tough life.

This is avery old story, No one can say that saw stop is not a good idea. However there a difference between an error and stupidity an an error. Safety devices do breed contempt. If you own a car with reactive cruse control and get in to one that does not have it you may be less alert than you should,

if you rear end someone you should not be able to sue the car maker. Saw stop is a great idea, and I would love to have one

but I do not want to have to buy one. Anything man made is subject to failure. If you manage to kick back a board that spears you could you blame saw stop? In the legal world we are in people try to blame others for there stupidity. To the lawyer who commented If you deactivate all the safety devices on something did not know how to operate it you should not collect a thing, and any lawyer that helps such a person is dishonest and should be disbarred for dishonesty. what has happened to taking responsibility for you own actions answer lawyers.

OK, you guys have convinced me. People should stop being idiots. They should stop doing stupid things. They should not sue manufacturers for their own mistakes. They should do all this perfectly 100% of the time.

And if somebody does make a mistake, then he deserves to lose a hand or an eye or his life, and if innocent bystanders are injured as a consequence, well that's their tough luck.

Safety devices are for loser wimps who should never have owned or operated machines that could injure them. I don't know why I didn't think of all that myself. It seems so obvious now.

I'm sorry you're so angry about so many things, usafchief. You must have had a tough life. Not angry about anything at all, or anyone, including you, baudi.... I just don't see something that can be affected by several variables such as damp sawdust collecting on either side of the tabletop,damp wood,rust etc as being a safety feature that can be relied upon.... My shop, in the summertime is cooled by an evaporative cooler that will raise the humidity level to around 40-50%, even higher when our monsoon season sets in... So, no doubt would have to have a means of measuring the moisture content of the wood, primarily within the first 1/16th to ensure that my wood was within the parameters of the device.... Of course, I could shut it off, but then my safety feature is gone isn't it??

How does this safety feature work when using a molding head cutter?? Or a full set of carbide toothed dado cutters? Would the trunnions and other pivoting points survive the sudden G load of bringing more than 1 1/2 lbs of spinning weight to a sudden stop?

Please, leave the sarcasm for the political sites.......

usafchief,

You should do a little research about Sawstop before criticizing it for not handling things that it does, in fact, handle.

this was/is my question.."How does this safety feature work when using a molding head cutter?? Or a full set of carbide toothed dado cutters? Would the trunnions and other pivoting points survive the sudden G load of bringing more than 1 1/2 lbs of spinning weight to a sudden stop?"

Going to SS website, I find that it will handle an 8" dado set, but you have to use a different cartridge.... No mention of a molding head cutter though.... One of the other postings on this subject matter asked the question of how many such stops could this machine survive, no answer was provided... Any idea?????

I'm reminded of my father's mythical beliefs in a dash mounted radar detector. My old dad a professional long haul driver placed all of his trust in that little black box beeping on his dash to save him from speeding tickets. It may have prevented a few however my dad collected more tickets in six months than I have ever in my entire life. Thats because I don't or ever will own a radar detector (distractor) that lulls one into a false sense of security. I follow the rules (sometimes) but always pay attention.

45 years sawing boards and I have never pushed a finger or miter tool into a saw blade because I pay attention. I use a sled, feather boards, face shield, splitters good lighting and stand to the side. One rule in my shop, stop and look at everything before you hit the power button. Doesn't anyone test fit or slide a guide up to or past a blade before they turn on a machine?

If I bought a Saw Stop and pushed my miter into it, hell yes I would make a clock out of it to remind me of the time & day I pushed it outside into the rain and bought an old industrial saw on e-bay.

Myself, I can't wait until that pecker-wood SawStop/Lawyer gets his ass sued off because his device failed. Oh it will happen not to me, but it will happen to one of you SawStop dreamers when you get smacked square in the face with a kick back.

I did the same thing. The blade and brake were cheaper than the miter gauge, so I don't feel too bad about it, other than feeling the need to kick myself in the rear.

Axton Grams

Great Idea, was going to hang mine on the wall as a reminder anywyas to always think before I cut. I set mine off cutting foil backed Styrofoam insulation and do the miter gauge test before every to prevent a miss-fire. I've even ran it in test mode a few times on wet wood and a foreign material to make sure i didnt set it off. Wouldn't trade the saw for any other even if it didn't have a brake!

I believe SawStop technology should be required for everyone who is stupid enough to need it:

For amatures who only play in their shop occasionally, for the untrained who have never spent time under a successful mentor, for those who are perpetually unaware of themselves, for the chronically distracted, maybe this is a better solution than finding more appropriate activities, but I doubt it.

Take an Indy car and put all the sensors and interupting controls and see how well a professional driver would do in a race. The analogy is very aprops.

I was taught early on to look at the fingers of anyone giving me advice in the shop. It has been good advice. Old guys with all parts working have offered the best insight, and I know who to avoid - like the guy sporting band-aids from an encounter while sharpening a plane iron. Has SawStop got a fix to help him not hurt himself?

It is great that the SawStop is available for those who want it. The saw itself appears to be well made, and I would definitely consider buying one if my 35 year old Unisaw ever gives out on me. I don't think anyone would argue that effective safety devices are bad or unnecessary. The problem I have with SawStop is their relentless efforts to manipulate the legislative process to mandate their product to all table saw purchases in the future. The ripple effect of all the used saws in the country being rendered not only worthless, but liabilities will impact saw users beyond the deprivation of choice in the marketplace. In California, legislation has already been drafted (by a recipient of Mr. Gass' campaign contributions)that would require all future table saws sold in CA be equipped with flesh sensing technology. Mr. Gass has chosen to impose his technology on our industry through politics and litigation rather than let his products succeed on their own merits.

No human being is diligent 100% of the time. It just doesn't happen. We all have distractions of one kind or another. Incorporating reasonable safety technology to prevent serious injury or death from known hazards is not making machinery "idiotproof". It's designing for human beings. The field is called ergonomics. A century ago factory machinery didn't have guards for in-running nip points. Now virtually all mechanical devices (with the exception of bicycles, and it's pretty hard to get your hand in there while pedaling) do. As we make progress in engineering and understanding ourselves more injuries and deaths get prevented. That's part of progress.

I set my Sawstop off with a Forrest Duraline blade, fortunately the trunnion was all the way down and the saw barely started, so I was able to use the blade again but had to replace the cartridge. My blade turned out to be around a 1/4 inch larger in diameter than a Woodworker II, which there is barely enough room for the cartridge adjustment.

I am more safer using this saw than my contractor saw, not because of the brake, but because everytime it kicks off it could cost me around $200. Because of this it has forced me to slow down and double check things more than before.

Great saw, however I do not agree with involving politics and legislation with this product. I think that the saw should be able to sell itself and not the government.

Perhaps bring some facts into this discussion?

Supposedly there are about 36,000 table saw accidents annually. Somewhere there may be an unbiased analysis and breakdown - amputations vs. kickbacks, etc. (I seem to remember the PTI did one - but while I would read it - I would also expect it to be as biased/inaccurate as any Gass might cite.. for their own similar reasons..)

For example, kickbacks. We know the use of a riving knife (and proper use - no crosscuts against the fence, etc.) will reduce that. By how much?

Then categorize the amputations... attempting to assess actual costs in the ER etc. (w/o allowances for personal 'loss of use'..)

We then start to get a handle of the total cost of mandating Sawstop vs. the cost of the accidents.

Any one suggest some URLS?

Chris

PS - personally, I try to use my Festool TS-55 for everything I can. About the only thing its not very good on is consistent repeatable long thin rips - then I use - horrors - a cheap Ryobi RTS-10 $130 saw. Surprisingly, its safety features - IMHO - are miles ahead of those on the old BTS-10 I used to have. The riving knife seems great. The split plastic guard is great. The pawls - I use them too. A good thin Freud blade... The worst is the fence always wants to lock down out of square with the blade. So I keep sample square 12" rips of the widths I usually use, and only lock it down with the sample flush to the blade and fence.

With all the safety features in place- all the time - I'm comfortable using it - for long rips only. So I conclude using a saw in this way - without sawstop - is not foolish.

It would seem that baudi might work for SS.

Log in or create an account to post a comment.

Sign up Log in