The Right Way to Sharpen a Card Scraper

The key is to turn a smaller hook to get better shavings.

Synopsis: Whether or not you use a handplane, the humble card scraper is a must-have tool for dealing with any tearout from the planer or jointer and for tricky grain that a handplane can’t handle. What transforms this piece of steel into a tool is the hook on its edge, often mistakenly referred to as a “burr.” Creating the hook is the key to good performance, and it’s very easy to do it wrong. Learn the right way.

When you think of working with hand tools, the humble card scraper is probably not the first tool to come to mind. But what it lacks in sex appeal it makes up for in ease of setup and use with no risk of tearout. Whether or not you use a handplane, the scraper is still a must-have for dealing with any tearout from the planer or jointer and for tricky grain that a handplane can’t handle.

What transforms this piece of steel into a tool is the hook on its edge, often mistakenly referred to as a “burr.” Creating the hook is the key to good performance. But a few common missteps when burnishing the hook prevent most woodworkers from getting the best out of their scrapers. I’ll show you the best way.

A great hook starts with a polished edge

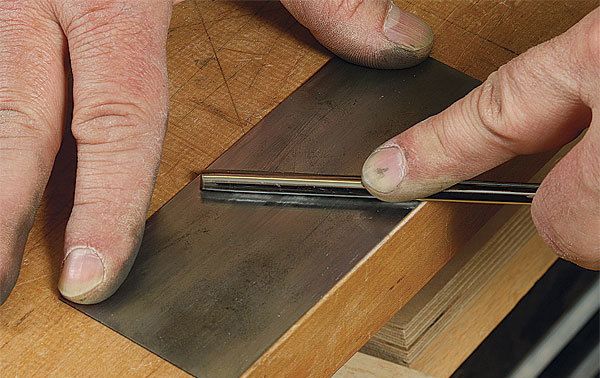

Just like a plane blade and chisel, a scraper has a cutting edge. And just like the edges on those tools, it needs to be polished and scratch-free to work its best. So, before you burnish the scraper, you need to polish the faces and edges. I use a DMT fine/ extrafine combination diamond plate ($90, woodcraft.com), because it’s more durable than waterstones and the polish it provides is good enough for a scraper. A less-expensive alternative is wet-or-dry sandpaper on glass. Start with 320 grit and work up through 600 grit.

A simple wood block helps with this task (and it comes in handy when you’re burnishing, too). A bandsawn kerf runs most of its length and holds the scraper square for filing, polishing, and honing. For hit the softer steel. Also, use a single long stroke to get from end to end. Short ones can create an uneven surface.

At this point, there probably is a slight burr along the corner. To remove it, alternate between polishing the face and edge on the extrafine diamond plate. The result should be a smooth, sharp corner, the foundation for a great-performing scraper. This sharp edge yields a single continuous hook—one that leaves a smooth surface and lasts a long time.

From Fine Woodworking #227

Online Extra: How to Sharpen a Card Scraper

For the full article, download the PDF below:

Log in or create an account to post a comment.

Sign up Log in