Table Saw Jig Chamfers Dowel Ends Perfectly

When making a large number of tote boxes with dowel handles, I needed a quick way to put a crisp, uniform chamfer on the dowel ends. I made this simple jig, which is also great for chamfering the ends of pins for drawbored mortise-and-tenon joints, when you have a lot of them to cut.

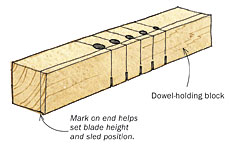

Start with a 2-in. by 3-in. block about 15-in. long, milled straight and square. On top, pencil a line about 1⁄2 in. from the front edge. Next, make several marks perpendicular to the line on top, spaced to accommodate your largest-diameter dowel. Extend them down the front face. On the drill press, use Forstner bits to drill through-holes of varying diameters on these centerlines. My jig starts at 3⁄8-in. and goes up from there. Their front edges should just touch the reference line from behind, as shown. Put the drilled block on the crosscut sled to cut entry slots into each hole at each centerline.

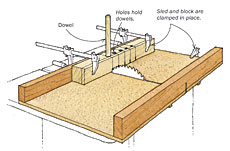

To use the jig, clamp it to the back fence of the crosscut sled with the marked end resting against the leading edge of the blade. Reposition the sled and raise or lower the blade to set the desired chamfer, then clamp the sled to the table. Now set the jig in place, with the blade sitting in the appropriate entry slot for your dowel. Clamp the jig to the sled’s back fence and turn on the saw. Push the dowel into the hole and slowly turn it around in either direction. The dowel will have a neat chamfer in seconds.

James Stansfield, Winchester, MA

Fine Woodworking Recommended Products

Double Sided Tape

Woodriver Circle Cutting Jig

MicroJig Matchfit dovetail clamps

Log in or create an account to post a comment.

Sign up Log in