Curved Panels for Furniture

Solid, kerf-bent core can be tapered, too

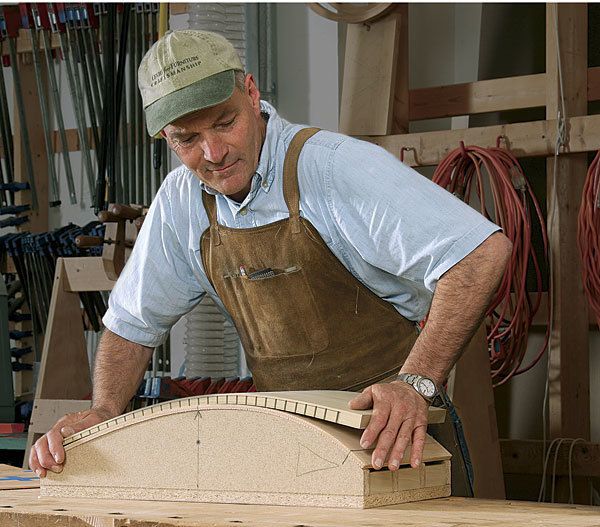

Synopsis: Learn to make curved panels that taper in thickness and look and behave like solid wood. David Haig has a system that uses a solid-wood core, kerfed across its width, encased in face veneers and steam-bent edging. This technique can be used for tapered panels or those of uniform width. It is quicker and more economical of material than bent-lamination, and allows the tightest part of the curve to be located at any point along the panel. Learn how he does it.

I first began bending wood to build my signature rocker. I learned steam-bending and loved the results I could achieve with chair parts. Then I began wondering how I could bend panels for case furniture. The technique I developed allows me to make curved panels that taper in thickness and will look and behave just like solid wood. Of course, with the same technique I can also make curved panels of uniform thickness.

To make the panels flexible, I use a kerf-bent solid-wood core. I sandwich the core between shopsawn 1⁄8-in.-thick face veneers, and add steam-bent solid-wood edging. I cut my face veneers and edging strips from a show wood, and typically use an inexpensive wood like poplar for the kerfed core. If the ends of the panel will be exposed, I make the core from show wood as well.

You can make tapered curved panels using bent lamination, but I find the kerfing technique much quicker and far more economical of material. Kerfing also allows me to locate the tightest part of the curve at any point along the panel; with bent lamination, the thick end of a tapered panel will not bend as readily as the thin end.

To produce an even bend, I cut all the kerfs to within about 1⁄8 in. of the full thickness of the workpiece. As I cut the kerfs in the tapered board, working from the thin end of the workpiece to the thick end, I raise the blade a partial turn for each successive cut. I use a standard combination blade, but the type of blade is not critical.

The spacing between kerfs depends on the severity of the bend I want to make. A tight bend might require kerfs 3⁄16 in. apart; for a gentle bend, 1-in. spacing might suffice. At the ends of a panel, where it connects to the cabinet, I’ll adjust the spacing to accommodate the joinery. Since both the kerfed core and the veneers are cut from solid wood, the panel moves with the seasons and should be joined just like solid wood.

For the full article, download the PDF below.

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in