How to Joint Lumber at your Router Table

No jointer? No problem. Learn how to joint a perfect edge on any board, using your router table.Let’s face it: milling machinery is expensive. That’s why many budding woodworkers choose to have their lumber surfaced on two sides at the lumberyard. While that will allow you to get by without a planer in your shop, how do you joint the edges of your furniture components square and smooth? You could try tackling it with a jointer plane, but learning how to use handplanes effectively takes years of practice.

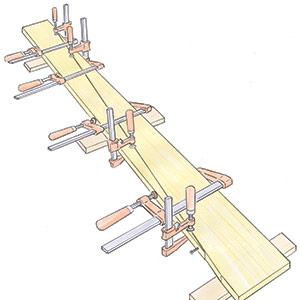

In this short video, furniture maker and Fine Woodworking contributing author Gregory Paolini demonstrates his technique for jointing wood on the router table. By using a router table fence that’s equipped with an offset fence, you’ll be able to dial in the thickness of cut by adjusting the position of your infeed fence in relation to the outfeed side. Although the fence used by Paolini in this video is rather pricey, constructing your own custom fence using MDF and plywood is certainly within reason for most woodworkers.

Comments

Great technique. Could also use a 1/16" shim on the "fed" side of the fence if you do not have a fence that has two parts to support the fed part.

Sure there are less expensive router tables than the Festool table he appears to be using (over $1,000). I too would love that table but cannot justify it yet. Rockler provides shims for the out-feed of their tables; Kreg provides rods for the fence on the PRS1045 table to accomplish a similar effect. There are probably other solutions out there or you can make your won with double sided tap and a think sheet of material stock on the outside of the out-feed. How precise are they in comparison? Likely less, but how much? It would be nice to know. I have no idea.

https://www.finewoodworking.com/2012/08/07/build-a-bow-arm-morris-chair-2 It would appear that this morris chair by Gregory is REAL furniture!

Squared the edges of rough lumber for many years by simply positioning on a square cut piece of plywood and running through my table saw. A lot less fuss and a lot faster. No offense against Mr. Paolini since I have all his books and DVD that I greatly appreciate.

Handy tip especially if you use a spiral bit for wavy grain wood and make cutting boards.

It's very interesting but for the average woodworker not very helpful since he's using a $1,000 set up that few of us can justify. Other publications have more useful setups to do the same thing at a much more affordable cost. I'm sure Festool appreciates the product placements for this demo.

Do you have an example using equipment normal people can afford? I choke at a router plate that is $200.

I do it with a shop made board edge /straightening Jig and a pattern bit. works great a setup is a lot easier. and doesn't even require using the fence. works great.

I have a less expensive router table with a two piece fence that is a lot fussier to set up but it works with relatively short boards.

My problem is a one person shop with LONG boards with a crook.

Anybody out there with a fix?

I would be doing this on my table saw if either side was perfectly flat; an in-feed feather board didn't really help.

My (inexperienced) router table attempts have me moving back towards the table saw jigs using a straight edge lumber fence guide clamped to the board with the crook...

I use an MDF extension to my site saw. The router pokes through. For this operation I use a board clamped as a fence, having shaved half a mm off half the length of the edge, and a notch for the router bit. It takes a couple of passes to line up the outfeed edge. Same result, larger table for long lengths. Cost about $25

Why are the stock board ends painted blue?

Nice method for jointing the edge of a small board, but what about flattening the face? This is a very expensive machine for doing limited edge jointing. You shouldn't own this piece of equipment in lieu of a jointer for this kind of work. You could pay less for a good quality jointer. Definitely a high end, versatile router table for all kinds of router table work, but as is common with Festool, all of their equipment is about 3 times above retail.

I have to agree with some of the other comments regarding the use of such a high priced router table as a jointer. Get a lower cost table and use the money saved to get a table top jointer.

I use a Kreg PRS1049 table, $550 or $440 with Veteran's discount. A 1/2" spiral bit gives a very clean edge. Setup for jointing couldn't be easier. I'm getting a jointer for Christmas.

Log in or create an account to post a comment.

Sign up Log in