Step 1: Mark the rabbet's width with a marking gauge.

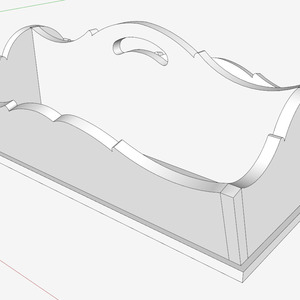

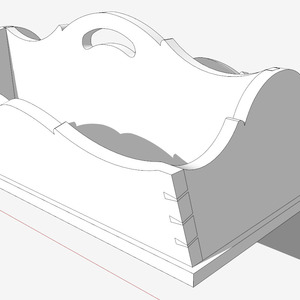

This was my third year attending the Working Wood in the 18th Century conference at Colonial Williamsburg. Even though I don’t make period furniture, I’ve always learned something useful and this year was no different. I often find myself needing to make a rabbet on a small piece (a small drawer bottom, for example) and not really excited about setting up the router table or dado set. That’s why I was excited when Mack Headley demonstrated a very easy and fast technique for making a rabbet by hand. I wasn’t able to get photos of him doing it, so I headed out into the shop when I got back to the office to give it a try myself. What’s so smart about this technique is that you don’t try to plane a perfect vertical wall as you remove the waste to get to the rabbet’s final depth. Instead, you plane to depth inside of where the vertical wall is and then plane back to get to the wall. So, it’s plane to depth and then plane to width. Don’t do both at once. Very smart and it makes the job a lot easier.

The photos above show how Mack does it. The only difference is that he was using a very cool wooden rabbet plane, while I was forced to use a metal shoulder plane. It still works, but I think I’ll be making myself a rabbet plane soon.

See all of the coverage from the Working Wood in the 18th Century conference at Colonial Williamsburg.

Comments

Is he cheating? He used a marking guage and a metal rabbet plane instead of sharpend stones. (re Jan 9th blog)

Matt, thanks for sharing. Good post - short & sweet - and the six photos pulled it all together.

AL

http://www.woodworkingwithajo.com

Excellent description and photo series, but it's a shame neither the writer nor editor know the difference between your and you're.

Thanks Matthew!

Hang on to these historical tidbits as 'woodworking in the 18th century' will soon be 'woodworking of the 21st century'

In the photographs the tool shown is not a marking gauge but a cutting gauge! This tool will give you more problems in use if you try to mark along the grain; with the tool trying to follow the grain. A cutting gauge is used to sever the fibers of the wood when marking lines across the width (grain). The appropriate tool to use along the grain is the marking gauge which has a spur and not a blade/ cutter.

When writers do articles like this to help the woodworking community, it is a shame that some comments pick on grammer or make other stupid remarks. This is a woodworking community trying to give each other good information - so the idiots should shut their pie holes and be thankful for such good helpful information. Nice article & photos Matthew. I'll be using this technique on my current project. Thanks again!!!

you know what else is great about these 18th century techniques? They're quiet! I'm at that age where finally I have the patience to pull the plane out for something like this rather than the added hassle of setting up the table saw or router table ........

and the shavings fall cracefully to the floor rather than MORE dust flying about my little shop space.

Looks like a nice technique for short rabbits, but for long ones I'll set up the dado set. I haven't been able to affort a rabbiting plane as yet, my financial mamager (wife) got sticker shock. As to WileyR420's comment. I think he needs to review "your and you're" usage. Your is a possive and you're is a contraction of you are. Thanks for the the tips.

By the way I sometimes have trouble with spelling.

Thanks for sharing, Matt. Please share the information on making the rabbet plane you are planning on making for yourself. Good article.

When I get a chance to read and see a great article that gives me tips, I appreciate it and the work someone has to do to get it together and then post it. When I see people commenting on the writing style or grammar, I have to respect that some people come with different expectations and needs to point out what they focus on, which is not the woodworking, or the craftsmanship or the learning. I suppose they can't help themselves. They are putting together their own pictures, tips and articles. Obviously I will then be able to appreciate what value they bring to the site. For now, it is an unfortunate distraction. I don't come to the site for grammar editorials, I come to learn work working.

I bought an old Millers Falls rabbet plane (#85), which works so well I haven't cut a rabbet any other way since. Pine 1x? No problem. 2x? No problem. Red oak? No problem. Cross grain? Drop the spur, no problem. At some point I realized I needed a rabbet in a piece of plywood.. yep. Worked beautifully.

I think I paid around $35 for it, including shipping, and it's in beautiful condition. I honestly don't understand why anyone would use a power tool for small numbers of rabbets. Setup takes about 30 seconds, and cutting the rabbet doesn't take much longer.

Now, for a large scale production run, where everything has to be perfectly identical, I can see using a power tool. Repeatability is one thing a router table does really well. But for a half dozen pieces or so?

Matt, great technique. Thank you! As I have shoulder planes but no rabbet plane, I will definitely make use of this.

However, if one did have access to a rabbet plane as Mr. Headley does, why would this be necessary? Doesn't a rabbet plane's fence already guarantee a straight vertical wall and constant rabbet width?

Nice Post, Matthew!

I do take exception to the criticism of those supplying grammar instruction. Is this not an educational forum and open to honest debate about things wood? Does it not matter how clearly we convey information about the processes and techniques?

Others, whom clearly paid attention in Composition 101, expressed their opinion that they would like to see better oversight and writing by the instructors and editors. I agree.

I also don't hold it against Matthew and appreciate that he passed on information he learned from his travels.

Lastly, I do not see rudeness in any of the suggestions asking Matthew and the editors to be mindful in editing stories, but I do see it in at least one of the responses: "so the idiots should shut your piehole!" That is very fine woodworking ability at it's best!

Micah,

That's a good question. The rabbet plane that Mack was using did not have a fence. And if memory serves me right, most wooden rabbet planes do not have fences. Fillister planes do, and you could use one of those to make a rabbet.

pcbg01207,

I suppose one could make that technical distinction between a marking and cutting gauge. Blogs are fairly casual, so I didn't. As for this not being the correct type of gauge for marking along the grain, I disagree. I always use a cutting gauge for marking and never have a problem with it following the grain. In fact, my experience with pin gauges has been that they do follow the grain. That's why I started making my own gauges and always use a cutter.

WileyR420,

Nice eye catching that one mistake with your/you're in the caption. When I was a professor, though, I always tried to be as charitable as I could to my students. I'm confident that both the writer and editor of this blog (the same guy, me) know the difference between "your" and "you're" (after all, I got it right in every other instance). Sadly, such knowledge doesn't always prevent a typo from slipping through. But that's one of the many hazards of being human.

--Matt

Matt - I had to do a google search for wooden rabbet plane to see what you were referring to. Thanks for expanding my knowledge of the seeming endless world of planes, and again for the excellent technique. I can't wait to give it a try.

This is the site where people learn different methods of work to achieve the same (or different) results. However, it dismays me to find people taking the grammar and spelling to task. I suggest those people go elsewhere such as book reviews or anywhere else to criticize. For those who get off their rocks, I suggest they go to youtube.com and turn on close captioning and see if you can read their Greek! Then they will criticize all day long with no end in sight! But at least, leave FWW alone!

Great article Matt. I have gained several tips from your article and the discussion thread.

I also appreciate pcbg01207's clarification of the marking gauge (pictured) and the follow-up comments. I have used both pin and cutting blade indiscriminately with mixed results. I am sure there is a technique to sharpen or replace pins and cutters. While I need to do both, I am using marking gauges with a circular disk cutter. I am not sure if I can sharpen or replace them? (If this is an appropriate question for this thread?)

Log in or create an account to post a comment.

Sign up Log in