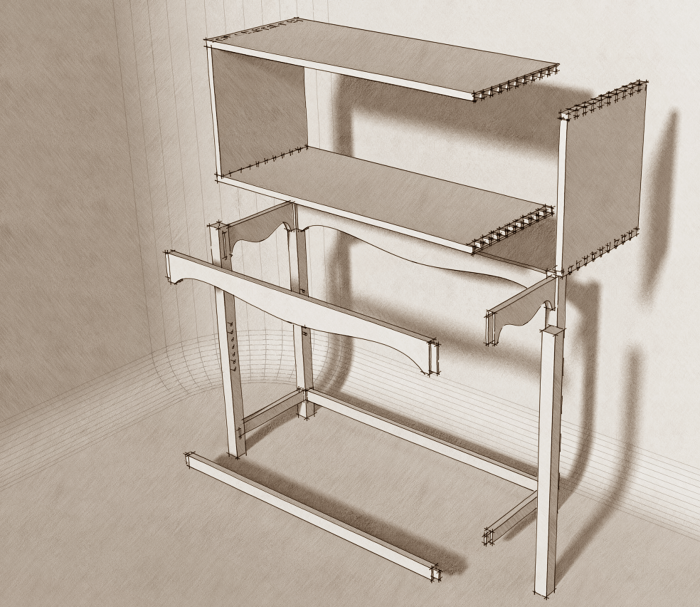

Almost exactly two years ago I wrote about a plugin tool set called Wudworx which has been very helpful for me in speeding up the process of drawing dovetail joints as well as basic mortises and tenons. I’ve demonstrated drawing these joints manually a number of times here on the blog. They aren’t really difficult to draw by hand but these tools really speed things up and let me move on to doing other things sooner. Recently the author added a tool for drilling holes. Holes are probably simpler in most cases than dovetails and mortises but this tool speeds up making countersunk and counterbored holes. It’ll also make arrays for things like shelf pin holes.

Take a look at this video for a quick demo of these tools.

http://blip.tv/play/gYhbg46sJwA.html?p=1

When making arrays of holes, the number you enter in the VCB is the number of copies in addition to the first hole in the same manner as arrays made with the Move/Copy tool. I didn’t demonstrate it but you can also make arrays by locating the first and last holes in the run and typing /n with n being the number of copies. Again, this is just like the Move/Copy tool.

If you prefer you can enter slopes for your dovetails instead of angles by typing, for example, 1:7 instead of a simple number such as 8. You can also create box joints with the Dovetail tool by setting the dovetail angle to 0.

There is a tool called Boardmaker included in the tool set. I didn’t demonstrate it but it might be a handy tool for you, too. It essentially combines the Rectangle and Push/Pull tool along with Create Component into a single step. The parameters dialog for the Boardmaker allows you to define a component name and the plugin simply appends an incremented number for each new board you create. You would probably want to go through and rename the components in Entity Info at some point.

While the Wudworx plugin is not a free one, I think it is well worth the money in the time it can save you. If you’ve been reading my blog posts for very long you know that I try to stress efficient methods of work in SketchUp. No matter how nice your SketchUp model is, you can’t sit on it or eat off it or sleep on it. You still need to go out to the shop and build it. The less time you spend drawing a project, the more you can devote to building it.

Comments

This is great. I'll have to get Wudworx and try it out. Thanks for writing about it.

Thanks for the information!

Chris Mobley

http://www.cmobleydesigns.com

Thanks king Dave another useful demonstration. I have the wudworx plugin and love it. I wasn't aware they added the hole drilling portion to the plugin. That looks like another keeper as well.

Cheers Dave keep them coming.

I love your easy to follow tutorials and I watch anything with your name attached.

Bruce Beatty

Dave, have been using the Wudworx plugin with great results for mortises and tenons. I have run into a problem when I try to make a leg from gluing up two boards (eliminates the purchase of a thick board, hard to find). I cannot get the plugin to do the mortise, will make the on the rail. Could you provide a method to complete the process. I do not make the a leg full size component so I can use the cut list to make layouts.

Thanks for any help.

Steve, I understand where you're coming from with laminating to get thicker stock for your legs. Unfortunately the Mortise and Tenon plugin doesn't handle that because the rail doesn't lie completely on the leg components.

I think I would opt to draw them manually. I'd copy the rail out so I can see its ends, draw the tenons using Offset and Push/Pull. then I would edit the leg components and add the mortise. I would basically do it as I show in https://www.finewoodworking.com/item/22911/a-fern-stand-demonstrating-my-drawing-process

An alternative that you might find useful would be to create two different sets of legs. One made of the pieces you would use to laminate the leg for use with the cutlist and a second set that are single components for the joinery. You could put the different leg versions on different layers and switch them on and off as needed.

Most likely, when you get to the point of cutting the mortises in the real legs, you no longer care that they were made of multiple pieces.

I do a similar thing for tables and workbenches. I draw the tops as single components but I make a separate version with the planks as individual components for the cut list.

I hope that makes some sense.

-Dave

Thanks for idea of using layers to get the most out of both plugins.

Thanks, Dave. Great demo, and very timely info on WudWorx, as I am in the process of designing a cabinet with drawers.

One comment on the recording - the volume level seems to be very low. I have the volume on my computer turned up full, and the volume in the viewer maxed, and it is barely loud enough, especially if there is any background noise at all. I have noticed this on a couple of your videos.

Hi I am taking your fundamentals for furniture design. I cannot get Wudworx Tools or dovetail ext. I did send them an email but it looks like there isn't support?

Also many of the ext you recommend are no longer available? I just bought 2024 pro. Also note that the flip tool has changed.

Log in or create an account to post a comment.

Sign up Log in