Turning Tools on the Cheap

Scrapers made from files and Allen wrenches.

Woodturners today are blessed with the luxury of choice. Dozens of companies make high-quality gouges, skews, and scrapers in nearly every conceivable size. All you need to outfit your shop is a credit card with a healthy available balance.

More Shopmade Tools

Homemade Hand Tool Cuts Leather Clean and True

Horizontal Router Table

Make Your Own Marking Gauge

It wasn’t always that way, of course. Until very recently, woodturners made most, if not all, of their tools-heating, hammering, and grinding a piece of carbon steel until it took on the shape and cutting edge they wanted. Japanese turners still make their own tools and have a waterstone next to the lathe to keep the edges razor-sharp.

Some of my favorite tools are homemade. I have a collection of scrapers that I ground from old files. And Beth Ireland, a well-known woodturner and teacher, gave me two lathe tools she made from Allen wrenches. One is a scraper that works rather like a bedan, and the other is a dandy little hollowing tool. I’ve used Beth’s bedan on both wood and aluminum with great results.

Grinding scrapers

Transforming a file into a scraper takes only a couple of minutes. Grind away the teeth on one face, working an inch or so back from the edge. (I know it’s wrong, but I use the side of the wheel for this.) Then hold the file at a 15 to 20-degree angle to the wheel and grind the profile you want. I made a couple of square-end scrapers, some with curved edges, and one that I use all the time to cut a dovetailed recess in a bowl blank for scroll-chuck jaws. This one has two cutting faces.

My scrapers cut smoothly and cleanly, but they don’t hold an edge as well as tools made from high-speed steel. No problem. With a couple of passes across the wheel, the edge is as good as new. These scrapers aren’t as thick or heavy as commercial versions, so they are more likely to chatter if I extend the cutting edge too far past the toolrest. That isn’t a problem either; I just get the rest as close to the work as I can.

Cutters from wrenches

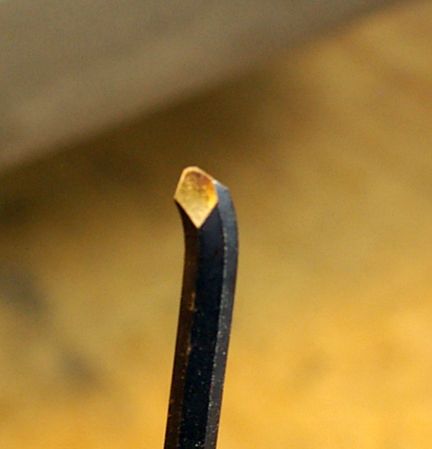

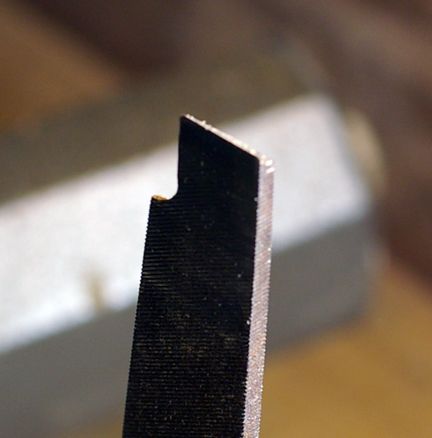

Beth Ireland made both of the tools I have from Allen wrenches, the kind with an extra-long leg. For the bedan, she ground away the short leg of a 7/32-in. wrench, ground the end square with an angled cutting face, and ground the two sides at an angle. For the hollowing tool, she ground away most of the short leg of a 3/16-in. wrench and ground the cutting edge to a point. She turned some simple handles, jammed the newly ground Allen wrenches in place, and the tools were ready to go.

Tools like these are meant for detail work or creating small objects. The hollowing tool is ideal for making a coffee scoop, for example. The bedan works well for turning pens, bottle stoppers, and the like. It gets into places where even my smallest spindle gouge won’t go.

Why homemade?

For a couple of bucks at a yard sale or flea market, I can buy a handful of old files and Allen wrenches. I get more satisfaction out of making a tool than I do buying one. And with the money I save, I can buy more turning blanks.

Comments

Good tips (sic) i like the idea of using or repurposing other tools.

Using the cold steel bricklayers pointing? tool for a heavy duty parting tool,cost $10

Scotty

Sorry, it's called a plugging chisel

Scotty,

I once watched Jimmy Clewes do a demonstration at an American Association of Woodturners symposium. Someone in the audience asked him a question about what tools are right for a particular job. "Whatever works," he replied. Words to live by, I'd say.

dh

Clewes is fantastic. I shot a few videos with him for FWW.com. Brilliant artist/technician and a stand-up guy.

although i am all about saving $ and re-purposing I have concerns about the safety of using old files as turning tools, aren't files tempered for hardness, making them brittle? with a high likelihood of breaking as a result of a catch. possibly sending shrapnel flying around your shop. also, grinding on the side of the wheel puts stresses on the wheel that it is not designed for that could fracture the wheel sending debris flying off at a high speed.I would not recommend any of this, putting your safety behind saving money is a bad idea.

Dear Waynedafoe,

I appreciate your concerns about safety, and I'd never recommend something that I didn't believe to be safe. Hence my note in the blog post that I know using the side of the wheel is wrong. However, I believe that a file/scraper shattering from a catch is a very remote possibility. As I'm sure you know, a catch happens when the side of a tool is unsupported when it contacts the wood. But because a scraper is always flat on the tool rest, it's always supported. If I were to misuse a file/scraper--for a roughing cut, say--it might catch. But scrapers are meant for light finishing cuts, which further diminishes the likelihood of a catch.

dh

I enjoyed teaching Mark Lindquist how to hot forge, harden & temper his own special wood turning tools. We were both teaching at Arrowmont in 1981 & he asked if I would show him how to do that in the blacksmith shop. His first tool was needed to turn inside a bottle neck form and was a tool he could not buy anywhere. He successfully forged, ground, hardened & tempered two tools with my instruction in his first two hours at the anvil. In my 40 years at the forge I have always enjoyed making tools and collaborating with craftsmen in other media. I know that you can forge many of your own tools, that it is easier than you may think and a great pleasure to work with tools you made. Paul Lundquist

I like to make and use homemade tools. My oldest son was learning how to work in the shop, and said, Dad you know why I like woodworking? I said no I didn't. He said the results were what mattered, not how you got their. That is the theme of this message.

I like to make and use homemade tools. My oldest son was learning how to work in the shop, and said, Dad you know why I like woodworking? I said no I didn't. He said the results were what mattered, not how you got their. That is the theme of this message.

waynedafoe is right. David Heim is wrong.

OLD FILES DO NOT MAKE SAFE TURNING TOOLS!

I assert that David is expressing an opinion supported by personal fortunate experience and intuition, not metallurgy.

"Old files are a readily available source of a hardened steel, there have been a lot of articles published that describe using them, and every gathering of woodturners has at least one "expert" on the subject. This doesn't make them a safe woodturning tool, and I (Russ Fairfield) am an advocate of NOT using an old file for making a cutting tool. Yes, we can anneal, harden, and temper them just as we would another piece of high carbon steel. But, the difference is that every groove in the surface of the file is a stress concentration where a crack into the steel is waiting to start. Many of these files may already have hairline cracks that have started to migrate into the steel. We can grind the surfaces, and we can do all sorts of heat treatment to temper the steel to a useable hardness, but it is impossible to remove a hairline crack. We cannot see them, and it only takes one (1) to make it a dangerous tool."

Source: Making Our Own Turning Tools by Russ Fairfield

http://www.woodcentral.com/russ/russ10.shtml

I spoke with Alan Lacer about his research last weekend. He also believes that files make dangerous turning tools. He has done quite a lot of research with metallurgists. For example, please see his article "Putting the Steel to the Test" published American Woodturner Summer 2008, Pages 52-54.

Joe W.

Some of you guys take the safety nazi bs way too far.

Woodturning has inherent dangers, and thus we take precautions, ie: face-shield, etc, etc. Worrying about "shrapnel" from a tool made from a file is ridiculous. You'd have to be doing something very wrong for that to even be a possibility.

And if any of you understood metalurgy, tempering or any other aspect of working metal, you would realize you can quickly and easily temper a file to a very useable state in short order and with very basic equipment.

I have several tools made from files, been using them for years without issue and I intend to continue doing so.

As for the hair-line crack stuff, if it's cracked, it's going to chatter like crazy and be very evident that something is wrong.

Think for yourselves, stop worrying and live a little!

Here's a better use for your old files. Send them to Boggs Tools in Paramount, CA for sharpening. As unbelievable as it seems, it is cheap and it actually works. You don't even need to clean them before you send them. Buy some tool steel to make tools and use your old files as files. http://www.boggstool.com

Log in or create an account to post a comment.

Sign up Log in