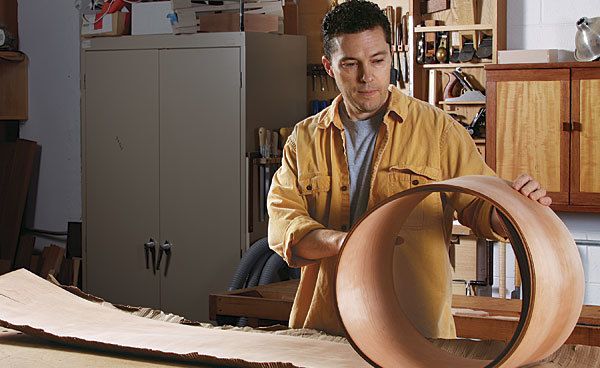

Synopsis: With vacuum bags, it’s easier than ever to incorporate veneer into your doors, panels, cabinet tops, and other furniture components. But before you start working with veneer, you need to learn how to buy it, cut it, join and seam sheets of it to get ready for glue-up. And who better to offer advice on the topic than furniture maker Craig Thibodeau? Here, this veneering expert gives you all the information you need on choosing veneer, marking and mending the pieces, flattening them, and then trimming and taping sheets of veneer to make beautiful book-matches, slip-matches, or other designs.

Veneer offers a wide range of furniture design possibilities because it comes in many sizes, figures, and wood types—many more than can be found in solid wood. With a vacuum bag, it’s easy to make veneered doors, panels, cabinet tops, and other components. But the first step in working with veneer is learning how to purchase, cut, join, and seam sheets of veneer to get ready for glue-up.

Commercial veneer—a forest of options

I almost always use commercial veneer—instead of the thicker veneers some woodworkers saw themselves. The pre-cut product is more convenient, and it offers consistent thickness and a wider variety of species and sizes. You can buy commercial veneer with a paper backing or in “raw” form without a backing. I prefer the raw variety because it lets me use both faces of every leaf to create decorative matches. It’s possible to buy a stack of veneer leaves cut consecutively from the same log for beautiful matching patterns. raw veneer is also thicker than backed veneer, leaving more room for sanding or mistakes. Buying commercial veneer typically means buying online. Look for a dealer that specializes in veneer, with a website that provides photos of actual inventory.

How much is enough?

First, create a project cutlist to determine how much veneer you’ll need. Measure the overall size of each veneered panel in the piece (veneered on both sides), add a couple of inches to the length and width of each panel for trimming and sizing, and add up the total.

For panels that need a decorative match, specify the number and size of matching leaves needed to create it. Also note any pairs of panels that need to be identical, like opposite sides of a cabinet or two matched doors. You’ll need twice as many matching veneer leaves to make each set. Because of this, the final number of leaves is as important, or more so, than the total square footage. Last, buy extra to prepare for mistakes and the unexpected. I add up to 20% for straight-grain veneers and up to 50% for figured or burl veneer, making sure the extra leaves are from the same consecutively cut bundle. The extra cost is easier to bear than trying to restock in the middle of a project.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Osmo Polyx-Oil

Diablo ‘SandNet’ Sanding Discs

Log in or create an account to post a comment.

Sign up Log in