Plus, senior editor Matt Kenney fills us in on the "dream jointer" he's getting ready to lug into his home shop.

Every two weeks, a team of Fine Woodworking staffers answer questions from readers on Shop Talk Live, Fine Woodworking’s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast!

Every two weeks, a team of Fine Woodworking staffers answer questions from readers on Shop Talk Live, Fine Woodworking’s biweekly podcast. Send your woodworking questions to [email protected] for consideration in the regular broadcast!

Click on the link at left to listen to the podcast, or catch it in iTunes. Remember, our continued existence relies upon listener support. So if you enjoy the show, be sure to leave us a five-star rating and maybe even a nice comment on our iTunes page. And don’t forget to send in your woodworking questions to [email protected].

Listen to Part II of our interview with Michael Fortune on Shop Talk Live Episode 35

Shop Talk Live 34: Bandsaw Master Michael Fortune

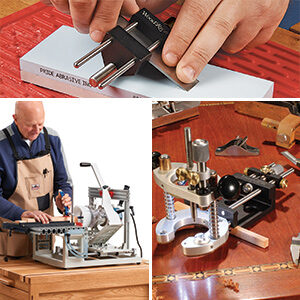

![]() On this week’s edition of Shop Talk Live, it’s all power tools, all the time, as the crew field a whole host of power tool and machinery-related questions. Plus, contributing editor and bandsaw master Michael C. Fortune sits down for an exclusive interview, we debut a fictional FWW-inspired television drama, and get the scoop on senior editor Matt Kenney’s new monster jointer.

On this week’s edition of Shop Talk Live, it’s all power tools, all the time, as the crew field a whole host of power tool and machinery-related questions. Plus, contributing editor and bandsaw master Michael C. Fortune sits down for an exclusive interview, we debut a fictional FWW-inspired television drama, and get the scoop on senior editor Matt Kenney’s new monster jointer.

Comments

Quote: Matt Kenney fills us in on the "dream jointer"

Big machines for big work small machines for"""".

I'm just curious what Matt is going to tell his wife when it comes time to explain why he has to have that 2000lb, 7hp, three phase cast iron machine at home.

What did I get out of it?

Going to have to try the wax/mineral oil finish.

I also concur with what was said regarding the recirculating filter.

Thanks for shop talk.

Chuck

Thanks for listening, Chuck! I'm a big fan of the beeswax/mineral oil finish for my cutting boards. Looks beautiful and clear (no yellowy tint) and it's easy to apply additional coats in the future as the finish wears.

Matt's jointer is safe and sound in its new home and I can't wait to see it at my next video shoot with him!

Best,

Ed

Concerning running three phase motors on single phase lines: why not use a variable frequency drive? These are small and light (consisting of semiconductors and capacitors--no transformers or motors) and have the added advantage of controlling motor speed as well (or just leave it set to 60 Hz). I am running my 240 V three-phase 1 HP drill press this way and it is great. I am amazed how this small little box can run that big heavy motor, but it does. Larger versions are available but eventually you get into the problem of requiring voltages higher than 240V. (By the way, why is it that motors are rated at 230 V, the actual voltage is 240 V, and everyone calls it 220 V?)

I have recently come across the podcasts and listened to most of them over the last month. I think that that the down to earth honesty that you bring to the problems inherent in the craft of woodworking is a welcome relief from the rigid dogma that seems to be preached from many other sources and is likely to do more to get people actually making something than anything else could.

Your progression technologically from the first show to the present has certainly been an improvement. If I had started at the first episode I'm not sure that I would have made it this far, if I didn't know that the sound equipment was going to have an upgrade. It sort of reminds me when I discovered that you could by a table saw blade that wasn't a "Craftsman" brand. It was amazing how better I became after a Woodworkers Warehouse opened up and I bought my first Freud carbide tipped saw blade.

The podcast interview with Michael Fortune was awesome. It was really great to hear about the interesting turns that his life has taken and the philosophy that he brings to his work. I've enjoyed every article that he has contributed since he has joined the FW staff. I've always felt like I've learned something even if I have no intention of doing what he is demonstrating.For example, I really doubt if steam bending is on the horizon for me, but I read his article on it several times. Just grasping the concept about how it is important to compress the fibers at interior of the radius as opposed to stretch the fibers at the exterior of the radius, made it worthwhile for me.

Until, I listened to the podcast I always thought that Michael Fortune was like the scary shop teacher whose aura is keeping people out of woodworking. Maybe it is the editorial style where the article constantly says "Fortune does this...." and "Fortune does that..." like Moses coming down the mountain with the commandments, or maybe its the photographs that accompany the articles, where he always has an incredibly stern look on his face. I realize that the photographer is concentrating on getting the technique in the photograph, but if your going to put the guy in the picture consider the expression on his face. When I see the sheer intensity on Michael Fortune's face, in the photos, I think that there is no way that I can do that, and if I ever saw him Id probably cross the street to avoid him, but know that I've heard him, he sounds like a warm wonderful person, so I hope that you do a few more interviews like this with other contributors.

Maybe I feel differently about Allan Turner and Mario Rodriguez because I've met them and taken some remedial classes from them at the Philadelphia Furniture Workshop. Having met them I know that they are not rigid and and I know that even though they teach together they will differ on somethings.I would think that either one of them would make a good guest on your podcast as they both have a lot of experience educating woodworkers.

Michael Fortune sounds a lot like John Lithgow. great episode!

Log in or create an account to post a comment.

Sign up Log in