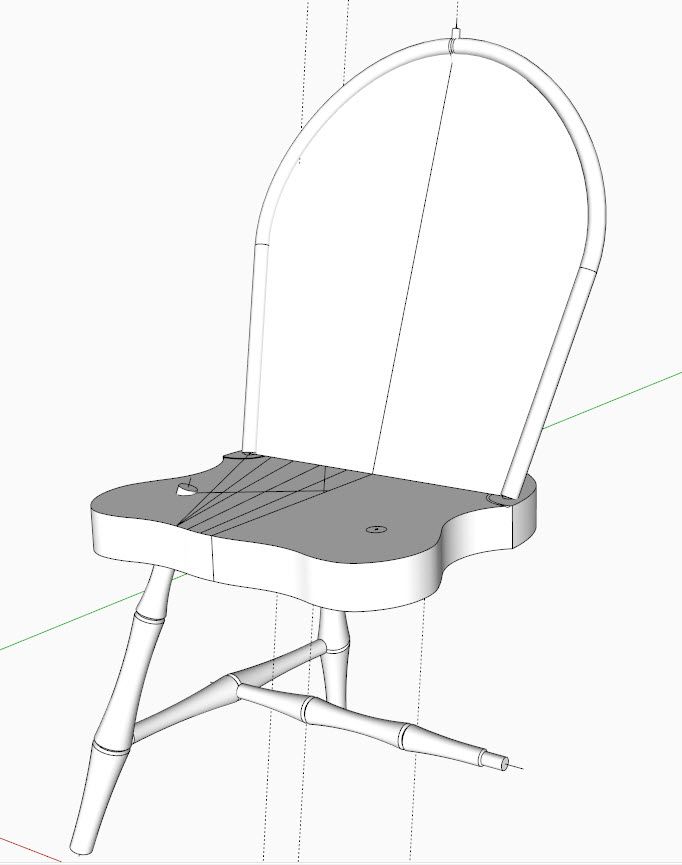

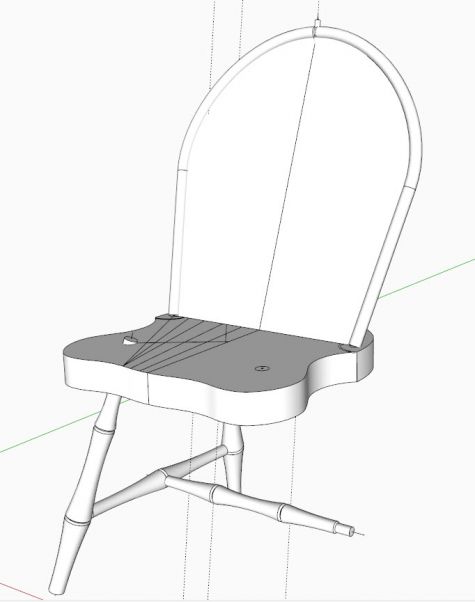

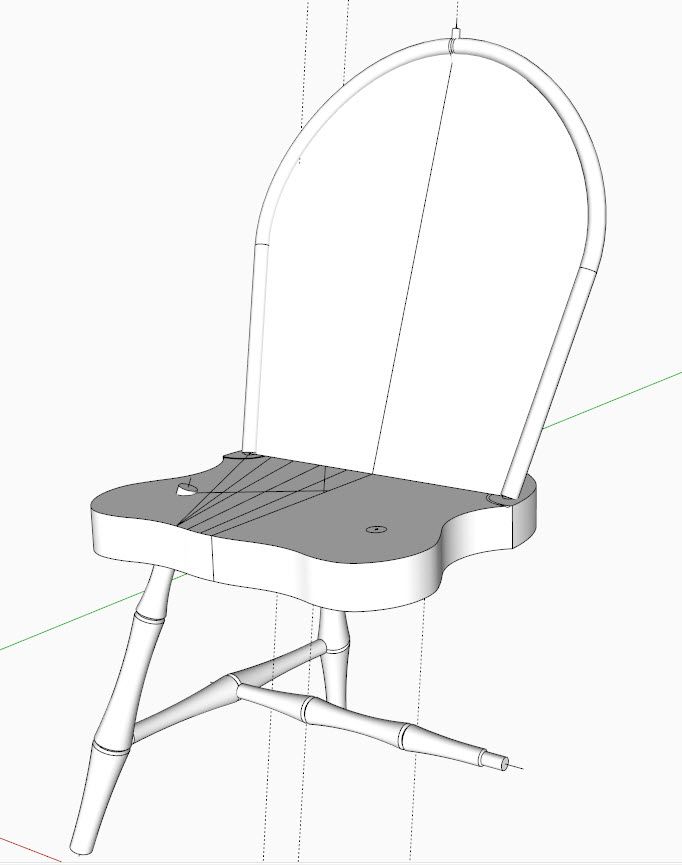

I’ve finished the seat and undercarriage, now the top part of the Windsor Chair is remaining work to do. That means steam bending a bow and turning some spindles. Unfortunately, the Fine Woodworking article we’ve been using for this series, provides little information on this upper section of the chair. So I’ll need to do some reverse engineering to assemble the top parts. Below is a video of this process.

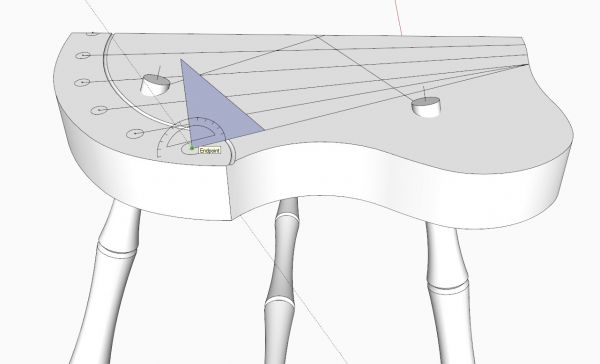

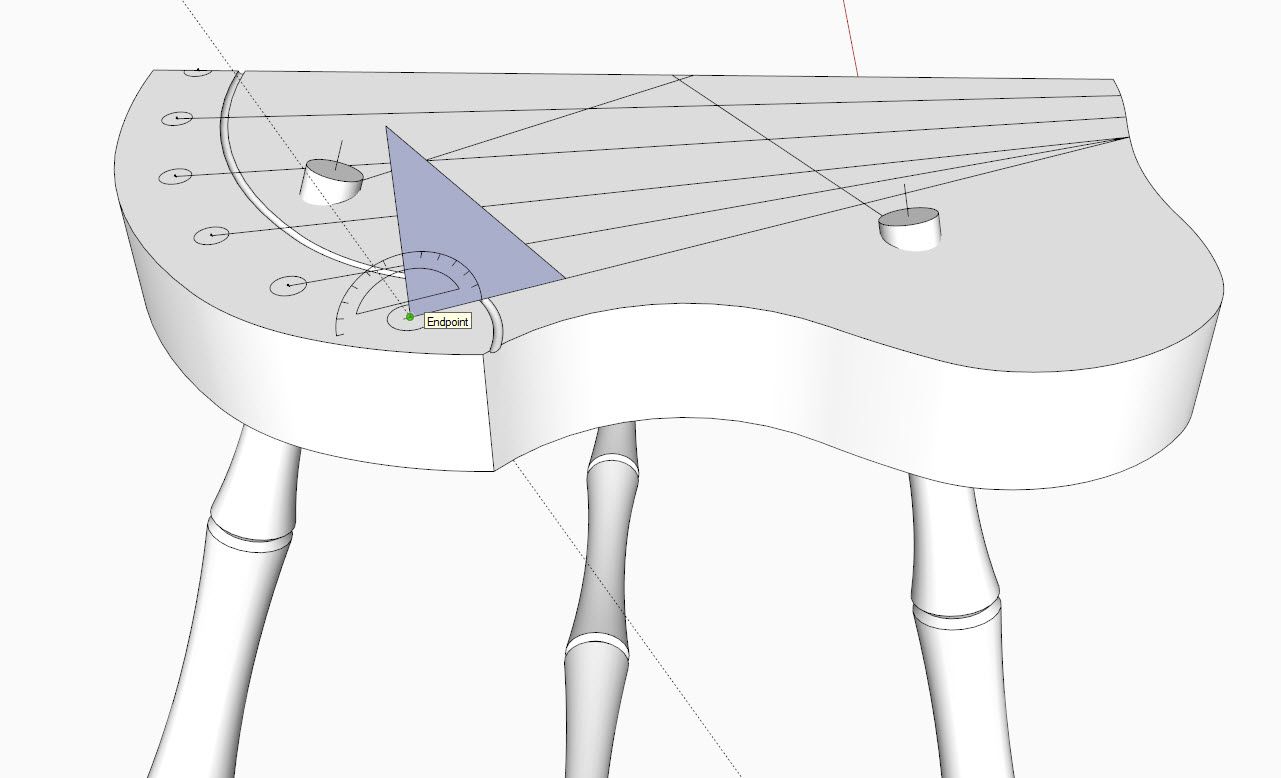

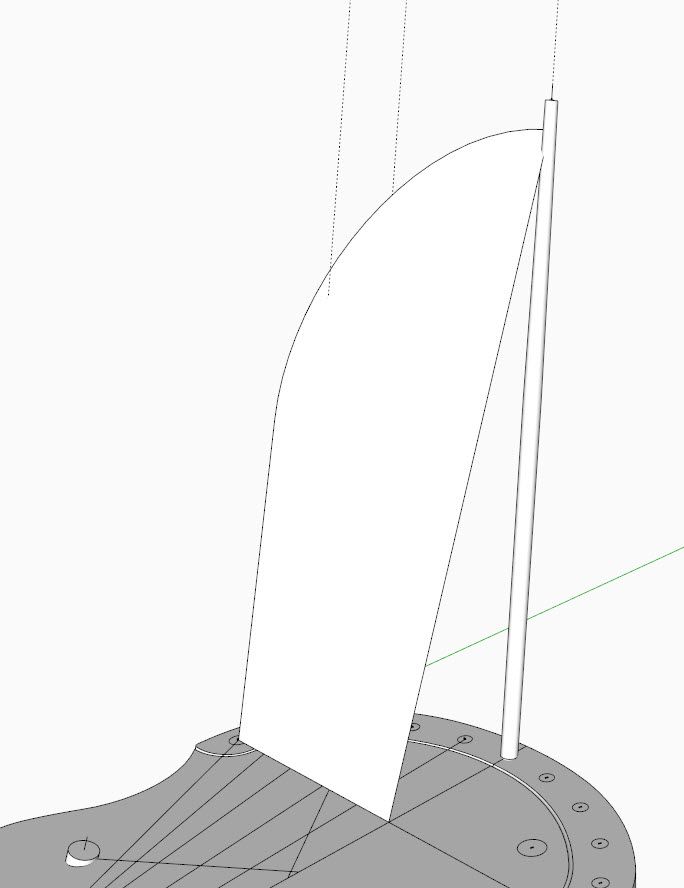

The first thing to do is set an angled guideline for the bow at the socket. Using the Sight Line for the bow, I’ll construct a small triangular face and set the angle according to the magazine article to 23 degrees. I can now delete the triangle.

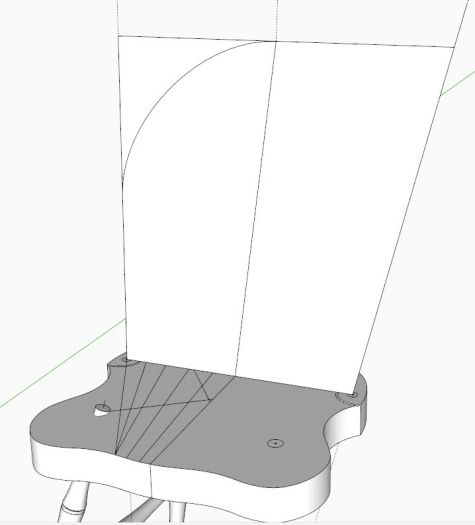

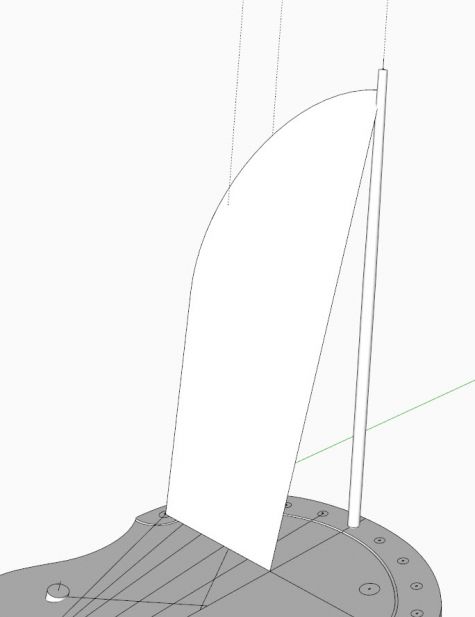

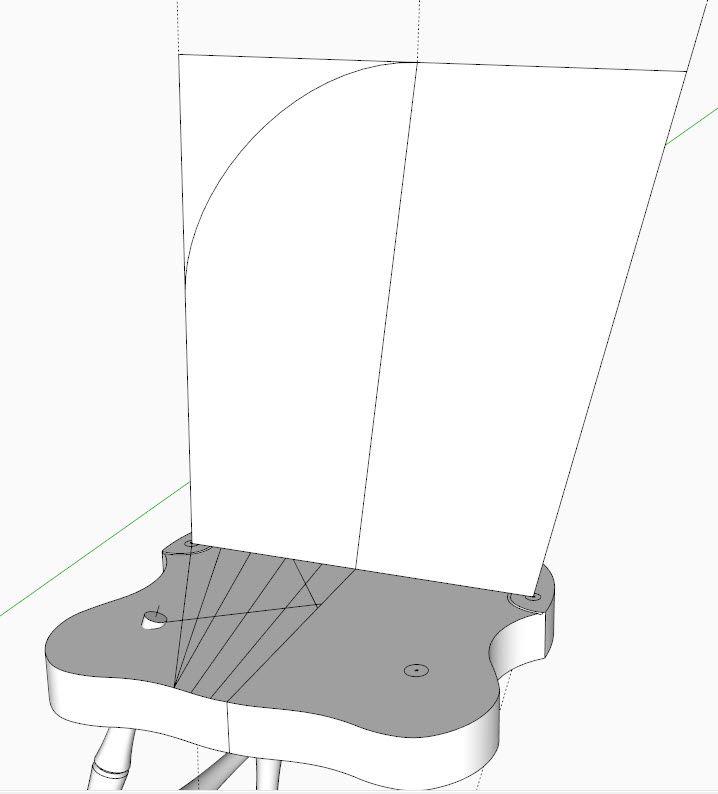

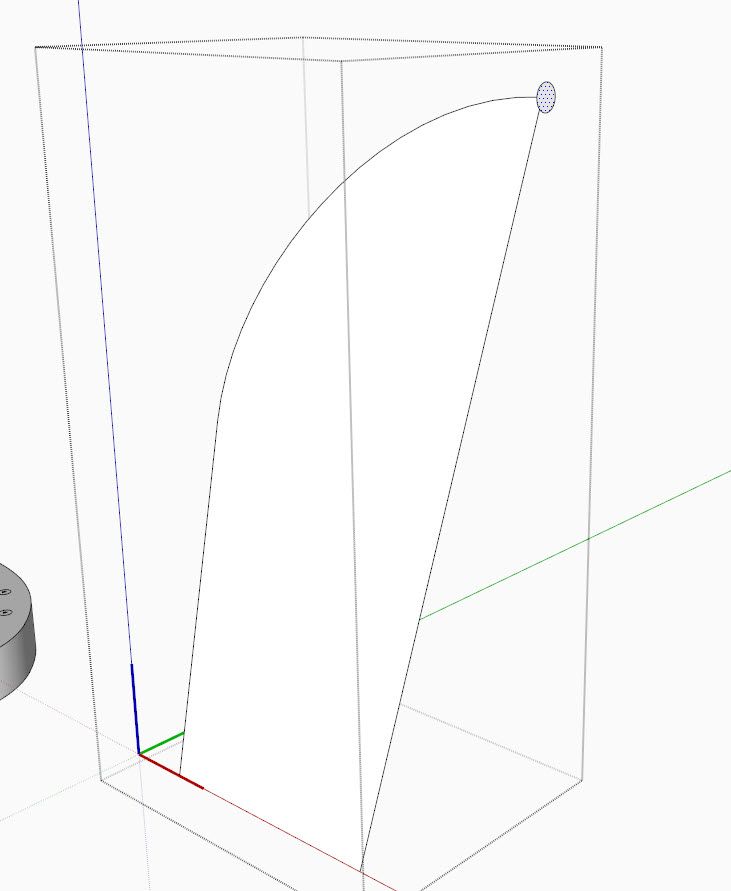

The Bow is drawn on a plane defined by these guidelines running through the seat sockets. So using the Line Tool I will make that plane on which the bow will rest. I’ll pick an arbitrary height at first. And here is the trapezoid on which we can draw the shape of the bow.

I used a Bezier Tool to draw the shape, but it can be done with the arc tool. The bows typically have a straight section from the seat socket almost to the midpoint.

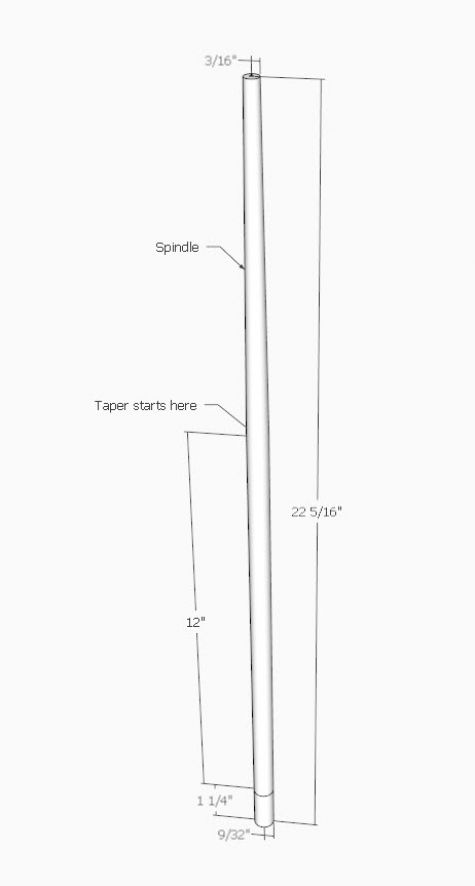

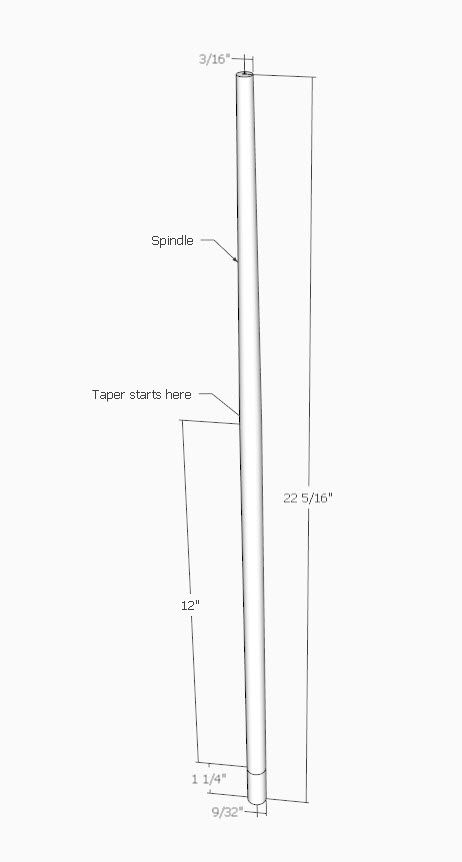

I’ve prepared a center spindle. The article provides some information about the diameters and taper, but not the overall length.

I select the path, then run follow me and we have the bow. There is quite a bit of work to do on this bow, and I’ll take care of that work in the next part of the series. Obviously that center plate or face will be deleted as we complete the bow details.

Here is the video:

More parts to go…..

Log in or create an account to post a comment.

Sign up Log in