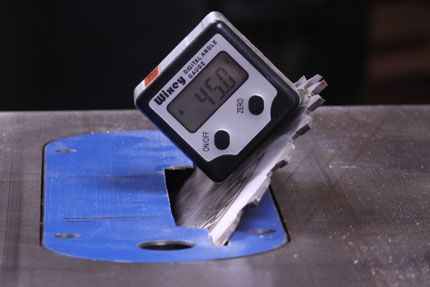

These handy little gadgets have been around for a while now, and it seems like a lot of people are using them. But just how accurate are they? I checked it out myself, and found that they are accurate down to 1/10 of a degree.

That sounds really great, but just how close does the angle need to be? It turns out I can put one on a tablesaw blade, and turn the angle crank enough to see a sliver of light against a square without the numbers changing- so they aren’t absolutely perfect.

That being said, they are very popular and many woodworkers swear by them for a variety of uses. Do you use one of these digital angle gauges? What do you use it for? Is it accurate enough for you?

Comments

I use them to align the blade on my table saw to 90 degrees.

I use mine to set the angle on my sharpening jig.

I do a lot of segmentation, accuracy is vital. Errors add up, this minimizes them.

I use one to set my band saw table perpendicular to the blade, but only when the blade is wide enough for the angle gauge to not rest on the teeth.

Also use it to set my table saw miter gauge to any angle. Clamp the miter gauge guide bar in a vice and zero the angle gauge to it then swing the miter gauge arm to the target angle.

I use mine for those common uses, but also on the router table to set dado depths. For instance setting in t-track into a cross-cut sled. I bride the bit and the track with the angle gage on top and raise or lower the bit until the Gage reads zero.

I use mine for those common uses, but also on the router table to set dado depths. For instance setting in t-track into a cross-cut sled. I bridge the bit and the track with the angle gage on top and raise or lower the bit until the Gage reads zero. Perfect depth.

I purchased mine to make a couple snare drums - requiring precise angle cuts down to the half degree. I've since used it to also make a curved chair seat and back.

http://petelawton.tumblr.com/tagged/Snares

I used one for a very deep mitered box, and still found error. Supposedly accurate to between .1-.2 degrees (depending on brand), which means possible gap of .8 to 1.6 degrees at the last miter.

Has anyone had any success with a setup block like the ones machinists use?

Don't just use it to set work angles on your machines, use it to also check any cut angles made or assembled pieces... it'll show up any angle error caused by machine error or wood movement etc.

I was demonstrating making a 45 degree angle sled for making boxes, and used my Wixey to check that the blade was 45 degrees before making that crucial first cut. The first angles cut with the sled were way off. The battery was weak in the Wixey. I've gone back to my Starrett. It doesn't take batteries.

I've used this digital angle gauge in a number of instances. I use it to check the joiner's fence to bed position. I have checked the drill press bed to spindle position. I have used to check the mortise chisel position. Won't be without it.

I have the Wixey gage for the position of the table saw fence. It is extremely valuable, particularly if you need to rip more material to a critical width. I also have the digital height gage.

I use mine to set the table saw blade for 45 degree cuts and then reset the blade to 90. Between eye sight and not being able to easily get down to blade level to check blade position with the a square or triangle being able to read the display is much easier. When I get to the 45 or 90 point I'm looking for I always go over and under a couple of times to zero in on the point I'm looking for and also account for any back lash. If the display is light (weak) then the battery is low and it may not be that accurate and I learned not to use it then.

I also have the Wixey Digital Angle Gauge. It works as advertised, but my workshop is on the chilly side in winter, and I found battery life to be very short, so I don't use it anymore.

Every time I go to use one of these digital tools the battery is dead

I use the Wixey to square my blade to the saw table as well as to set up for miters and to square my tenoning jig. I have found that some of my throat plates are not perfectly flat and that can throw off the measurement. When I set up to miter thin stock for boxes I zero the gauge on an actual piece of the planed stock in cutting position. When I do this I get very accurate miter settings. Same for a miter sled since the sled determines the "0" position rather than a throat plate. Of course you have to be careful to keep the base corner of the gauge parallel to the plane on which it was zeroed when you set it on a tilted blade.

It's an interesting gadget and little more than that. Like all new gadgets that promise a lot, they (we brought in a Beall and a Wixey) got considerable attention when our group (I work in a shop with 18 master builders of all ages) got hold of a couple of them. We soon found that the best they will do is find the "ballpark" settings for angles somewhat better than the angle indicators on the front of our saws.

If accuracy is your goal, trust a good try square before this gadget.

I use the Wixey and find that it gets me pretty darn close. I use a machinist square if it has to be perfect, but most times I can set up digitally and then when I check with the square I don't have to make any further adjustments. I also have a digital scale on my table saw to measure the fence to blade distance. It's great as it reads both American (nee Imperial) units as well as metric. It also works like a digital caliper so that you can move the fence a precise amount from any position; you set up for the first cut, zero the unit and then you can move the fence exactly 13mm or 1/2" or whatever without doing any arithmetic.

Now that smartphones have level apps (I use Xclinometer) I find that I can also check angles and level in the field easily as well. It doesn't work as good as the Wixey as there are no magnets and the long edge of the phone has buttons that can upset things, but even using the short ends it is still quite useful and pretty accurate.

I have yet to receive a Wixey tool that did not ship with dead battery. That should tell you something! I find they must be stored with the batteries removed or the next time you choose to use a Wixey tool - the battery is again, dead. They all seem work reasonably, although, not super accurate. Still, Wixey had better work on a battery life solution sooner than yesterday.

Wixey tools are nice for play time, but if it has to be accurate, I reach for my Woodpecker's tools. Thanks anyways!

I use the Wixey on the table saw and then verify it with a machinist's square and 45. I also use it when I am sharpening my plane irons and chisels and have found it to be so close that the difference is in the thousands. Here's my caveat: these digital devices help me get it fine for me. I'm a hobbyist woodworker and spend most of my time in the 'setup' mode. Sometimes I 'wear myself out' adjusting and fine tuning my setups striving for that 'perfect cut'. The cuts take no time at all and I am usual very happy with the outcome. The digitals are very helpful for me with calipers and micrometers too.

The Wixey gauge is accurate to +/- 0.1 deg. This is sufficient for setting the blade angle on the table and band saw for most applications. I certainly get very close. If I require something more accurate, as when I make segmented bowls, I always check using more precise methods (segmenters know the methods) and then tweak the angle.

Always turn it off before putting it away. Battery seems to last over a year. Always have a spare on hand.

They are perfectly accurate enough for all woodworking tasks, but the battery life is appalling. It should have auto-off and last at least a year. A slightly unfair comparison but, my Mitutoyo digital calipers last at least five years with constant use on a tiny battery.

These guys need to re-design with battery life in mind.

Then it would be perfect.

I use my Wixey on a regular basis, and I find it to be perfectly adequate. A miter cut at 45 is dead on according to my Starrett. I teach beginning WW classes at a local store where we make a small box. My students are always blown away by the perfection of the miters. I angle the blade based on the bed of the miter sled because the throat plate in the class table saw is not always level. THANK YOU, Mr. Stowe for that design! I always give you credit, and try to sell your book or video. I replace the battery every couple of years. Be religious about turning it off.

With regards to battery life - check your battery. SR-44s will get more than double the life of a LR-44s. SR-44s start at 1.55V and stay around 1.5V until about 80-90% used before the voltage drops. LR-44s start at 1.5V but drop below 1.3V at 40-50%. These displays usually need 1.3V to run.

Today I was going to make a wooden gauge for setting the Wolverine tool rest on my slow-speed grinder. Before I got started I thought about my Wixey gauge. I used a magnifying glass and a bright flashlight while I adjusted the tool rest so the stone was rubbing midway between the toe and the heel of the bevel on the plane iron which I'd clamped to the tool rest. Once I was satisfied with the adjustment of the tool rest I set the Wixey on the table of my cabinet saw. Since the saw never moves it is a good reference point for zeroing my Wixey. I zeroed the gauge then put it on the grinder tool rest. I recorded the readout. Then I adjusted the tool rest for block plane irons and recorded that setting as well.

This should make grinding easier.

Log in or create an account to post a comment.

Sign up Log in