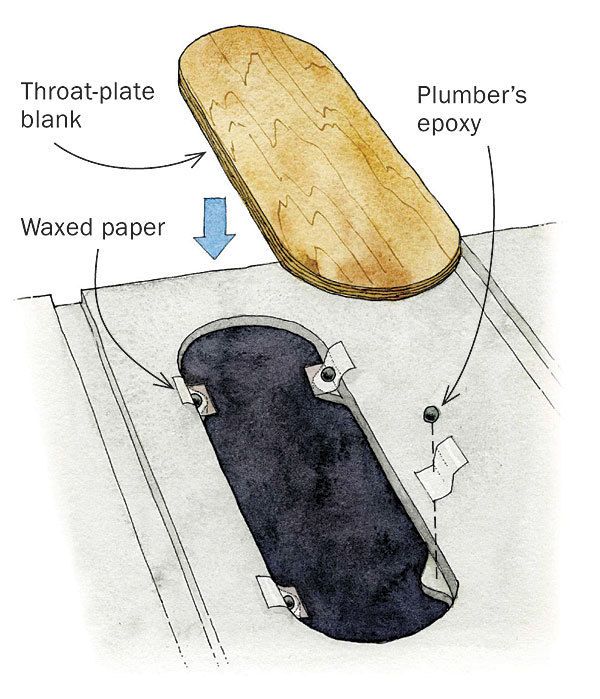

Plumber’s Epoxy Levels Table Saw Inserts

I recently upgraded my tablesaw with a new riving-knife attachment, an addition that meant I also needed all new zero-clearance inserts. Fortunately, I found a great, quick way to level a new insert. To make the inserts, I cut blanks to length and width, then used a factory insert as a pattern to rout them to perfect size. Here’s the clever part: To install one of the new inserts, I kneaded four pea-size balls of quick-setting plumber’s epoxy and placed them on waxed paper on the corners of the saw’s insert support ledge. I then set a blank insert in the opening on the epoxy balls and, with a straightedge spanning the insert, gently pushed the blank down until it was level with the saw table. After 5 minutes I removed the blank, with the epoxy adhered to it, and set it aside to cure overnight. The result is a perfectly fitting zero-clearance insert that’s level with the table.

Lenny McHugh, Pottsville, MN

Fine Woodworking Recommended Products

Rockler Dust Right 650 CFM

Hedgehog featherboards

Shop Fox W1826

Log in or create an account to post a comment.

Sign up Log in