Tip for fitting a handle to a socket chisel

Missing the handle for that nice old socket chisel? A small piece of clay makes an exact model of the tenon you need to make.

In a recent audio slideshow showing how to make custom socket chisel handles out of curly maple firewood, I came up with a little trick to make a pefectly tapered tenon for any socket.

If you have an old socket chisel that’s missing the handle, just simply push a piece of modeling clay (or plumbers putty) into the socket. Slightly twist the clay as it’s removed, and then you have an exact replica of the tenon you need to make. Use calipers to take measurements from the clay and then turn the tenon on a lathe. After using a small gouge and parting tool to make the taper, you can use a small flat piece of wood with sandpaper to clean up the tool marks and make a nice even taper.

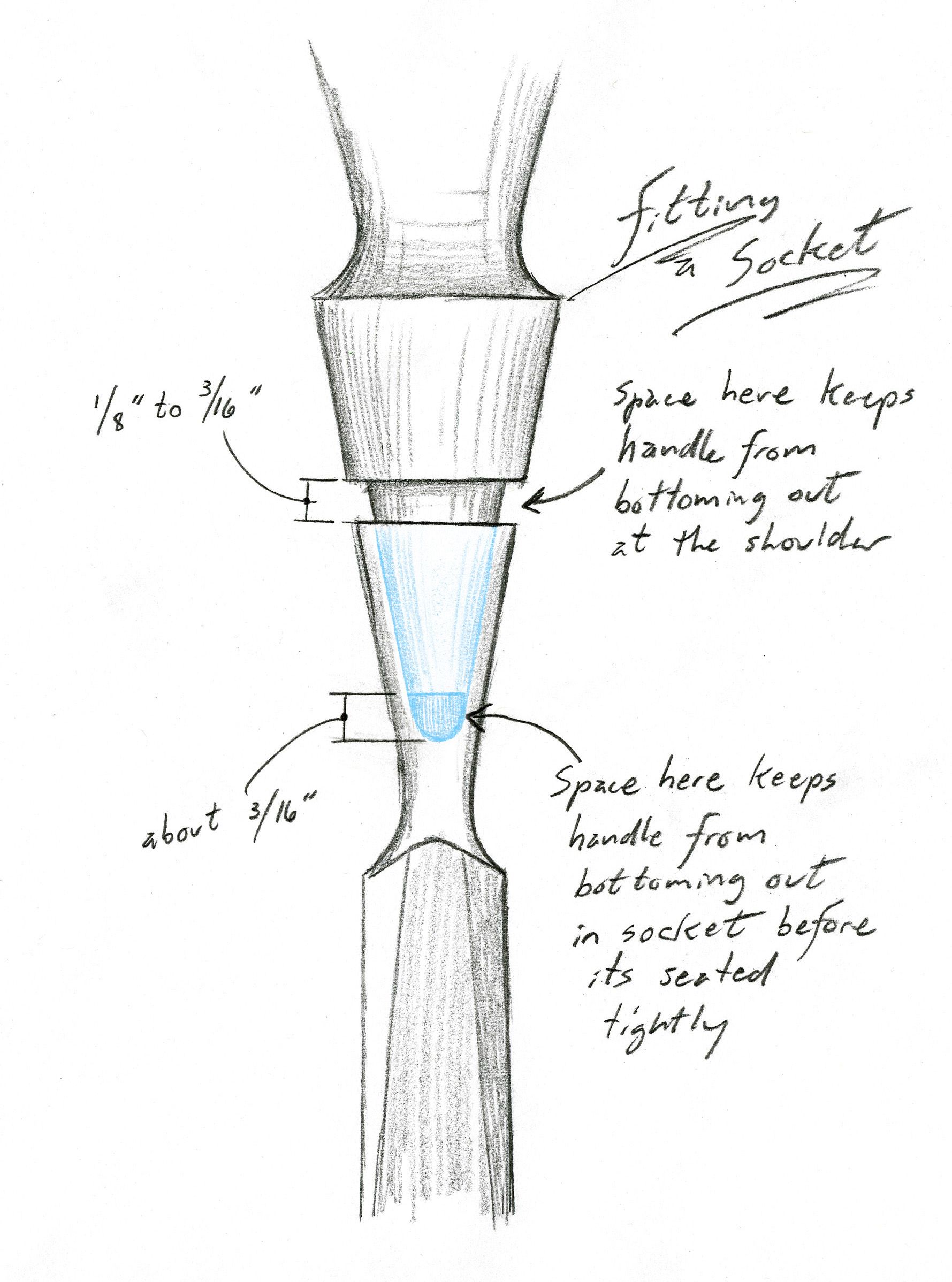

I did a quick sketch to show how to make the tapered tenon sit in the socket just right.

Comments

Thanks, John. Good tip. Beats pure trial & error!

Do you have a trick, John, to keep the wood in the socket in dry weather? Epoxy or some other adhesive? Thanks.

UncleNorm,

The only trick I know is to fit the socket when its dry (you can even heat the socket a bit to really dry it out) making sure to leave the spaces above and below as shown in the drawing above.That way you can still knock it down tight during those extra dry months.

If the socket is fit well, it's designed to tighten every time you give it a smack. Epoxy would probably work, but you would never be able to remove the handle, say if you wanted to replace the leather washers, or swap it for a longer paring handle. Hope that helps!

John

I like polyurethane adhesives (Gorilla Glue is one; there are others) for fitting handles. The adhesive foams a bit while it cures, filling in all the gaps; and the material is slightly elastic when it's cured, so it's shock resistant. It's also very strong.

Example: I fitted a handle to a 2-3/4 lb. blacksmith's hammer, using steel-filled epoxy. The epoxy cracked and the handle loosened after only a few days' work. I removed the handle (no easy task with the wedges) and cleaned off the epoxy residue, then re-fitted it with a urethane (I think that one was Dow-Corning Waterproof Glue, not on the market any more). The head is still tight, 20-odd years later.

I shudder to think of trying to remove it, though.

I think Pete999 is on to something. Epoxy has its merits but since it is brittle it does not resist shock well. But if one were to use it and needed to get pieces apart, heat would work as most epoxy begins to fail at about 180 deg F. I have been using elastomeric sealant for a variety of such uses fasteing dissimilar

materials as chisel handles. Again heat is the release agent.

Hair spray works great. 3M 77 contact spray also does well

Thanks for this tip

Amazing

Good luck!!!

Just Amazing

Log in or create an account to post a comment.

Sign up Log in