Curve Cauls Precisely for Even Pressure

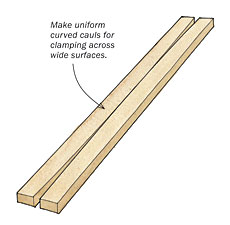

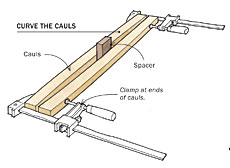

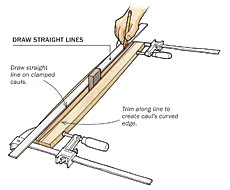

A recent project called for a veneered panel, and I needed curved cauls for even clamping pressure across the piece. But I wasn’t sure how much of a curve to create—the right amount could vary with wood type, length, and thickness. I decided to measure how much the cauls would bend under clamping pressure, so I’d know how much wood to remove. Rest two matched caul boards on the bench and place a small scrap between them, at their centers. Make the scrap thick enough to create space between the cauls—but not too thick. Mine was 3/4 in. thick. Tighten clamps at each end so that the two caul boards bend toward each other. Make sure the gap between the ends of the boards is the same at each end. Now lay a straightedge along the inside edge of each caul board, making contact at the center with the scrap. Mark a line from end to end on each board. Remove the clamps and bandsaw or rout away the material along the resulting line. Under clamps, the cauls will straighten out and even pressure will be applied.

Jim Richey

Jim Richey

Jim Richey

Nicholas Phillips, Silver Spring, MD

Fine Woodworking Recommended Products

Bahco 6-Inch Card Scraper

Veritas Wheel Marking Gauge

DeWalt 735X Planer

Comments

1. Does the thickness of the spacer depend on any other dimension; e.g., length of the cauls, thickness of the cauls?

2. Once the spacer is in place and clamps are applied at each end of the cauls, how does one determine the gap to leave between the ends of the cauls as the clamps are tightened, if any?

I have the need to clamp this way on an existing project. Thanks in advance for your response.

Log in or create an account to post a comment.

Sign up Log in