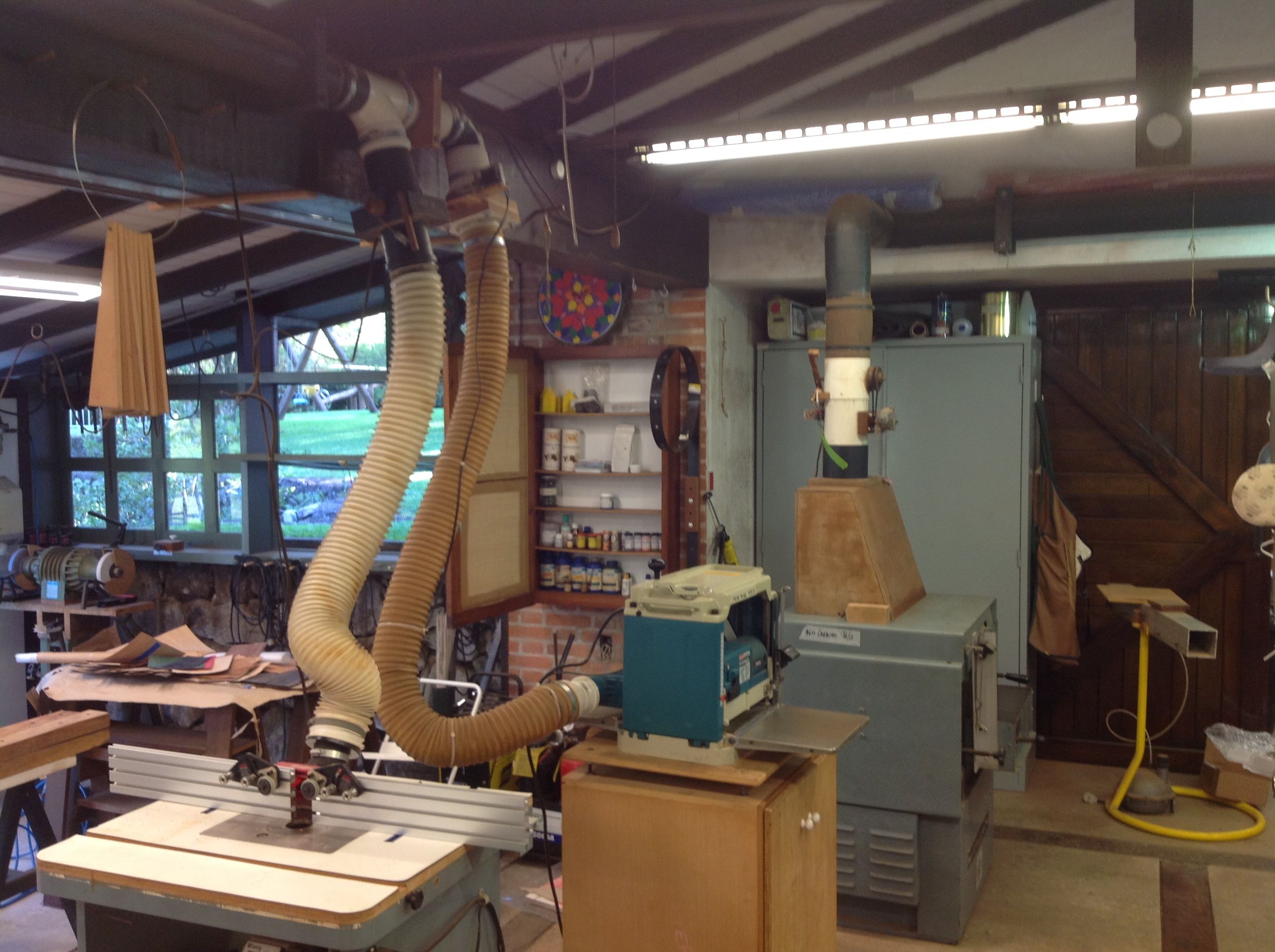

Home made automatic blast gate

Brazilian Wood Working

Revisiting Dust

When I walk into a spotless wood shop I always think its owner either has no work or he (or she) has plenty of time or help to clean up. Or, they have an amazing dust collection system with discipline to match. My visit to teach a group and private veneering classes in Sao Palo, Brazil reminded me of the latter.

The private shop I worked in was spotless, absolutely free of any dust, and I soon noticed a variety of ingenious homemade dust collecting systems and a method of work that inspired me to revisit how I handle my dust.

Dust is a constant battle with that little annoying pile; I never quite get it all; I have to remember to turn on the dust collector; then open and close blast gates before operating every piece of equipment; or move and connect hoses to specialized tools; drag around my vacuum with one bad wheel and a stubborn hose to suck up the fine film of grey matter. Put on my dust mask. Turn on the air cleaners to capture another toxic cloud…the list is about as endless as the dust.

I sweep, I brush and I sweep more with every size broom known to man. The fact is, I am either lazy or in a hurry when making only one cut, which means the dust quickly adds up, too. It’s fine and invasive and seems to be everywhere no matter what I do.

I admit, laziness probably gets the better of me. I find myself not always turning on the dedicated vacuum as two switches are SUCH a hassle.

The fact is, dust control is simply discipline and a method of work.

When I saw this new system in Brazil, I thought I would share some of the gadgets and method of work they used to manage this essential dust issue. I hope it will be helpful for all woodworking shops, big and small alike.

[[[PAGE]]]

Exile Your Dust Collector

First, the dust collector was outside the shop for sound reduction and easy cleaning and dust debris removal. Cleaning out a system in my shop always fills the air with the finest dust which seems to defeat the system’s purpose.

Second, every stationary piece of equipment is connected to the dust collector with additional ports for mobile equipment, as well as well-placed floor ports for sweeping, which they rarely do. (I will get to that further on.)

Typical dust collection systems use costly metal spiral ducts; to save on costs, my Brazilian hosts use a light-gauge PVC pipe with a bare copper wire that is grounded and runs through ALL the pipe. This is essential as dust moving through plastic pipe can build up static electricity and become explosive.

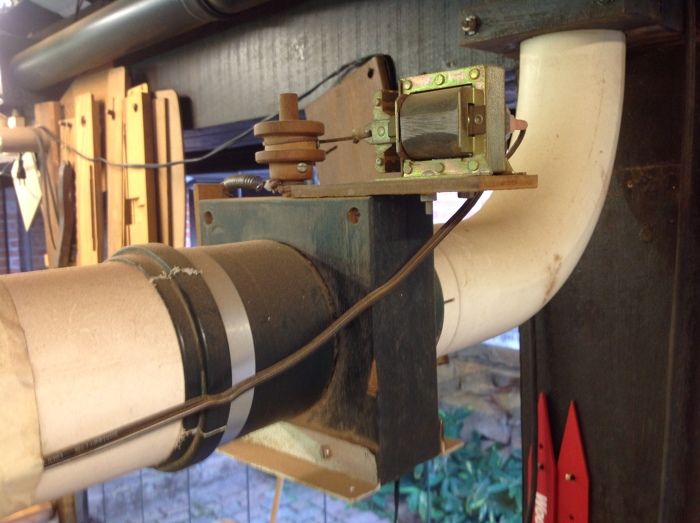

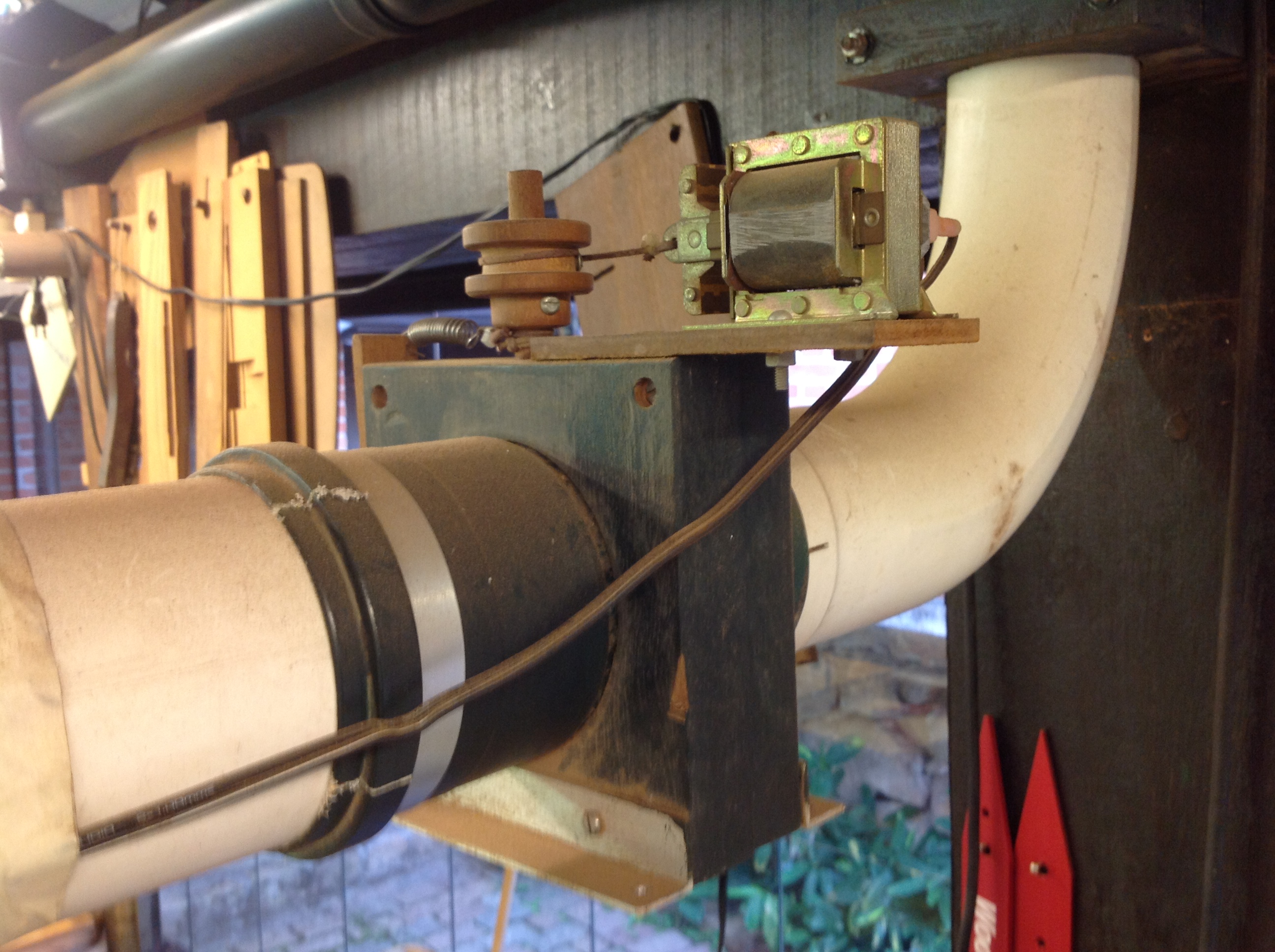

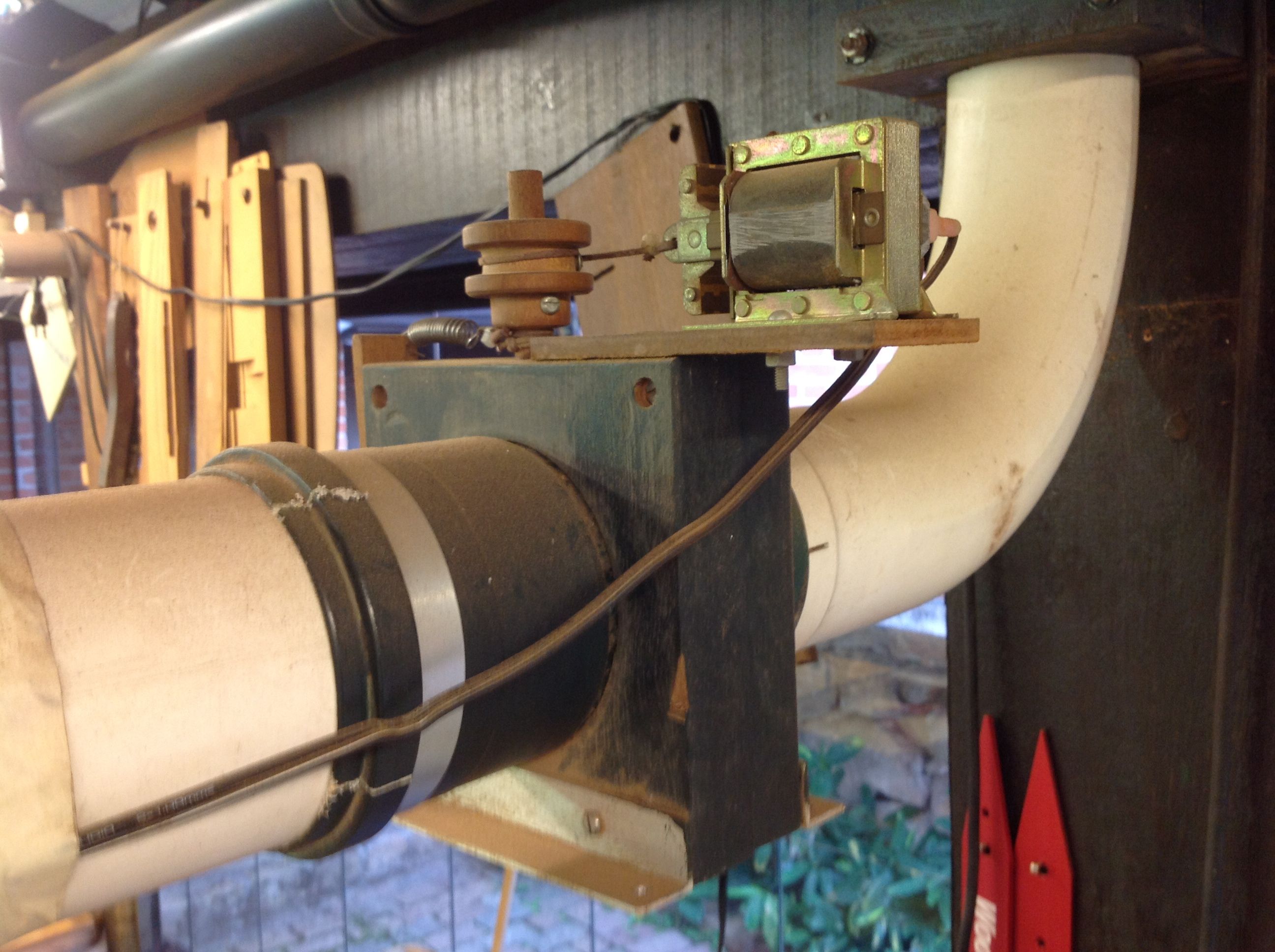

Ingenious Shopmade Gizmos

The homemade automatic switching was most ingenious and was the key to capturing dust each and every time. As each piece of equipment is turned on, the dust collector is activated by a current detector that is located in the shop’s main circuit panel. This homemade system is cost effective and very efficient.

This system also maintains maximum dedicated suction to each piece of equipment while in operation.

In addition, another approach to maintaining dust, is instead of sweeping, they vacuum everything all the time. The vacuum was used to clean table tops, floors, equipment, everything, and I could not find a broom. This seems to be the key, a disciplined method of work approach: vacuuming instead of sweeping. They had a number of portable vacuums strategically placed around the shop. All were very accessible with the hose and wand hung up and ready to go. I couldn’t tell if they also had a bad wheel like mine because I never had to move one.

Lastly, for sanding, they didn’t have room for a downdraft table, but again they used a dedicated vacuum system connected to their orbital sanders. The vacuums were the kind that automatically turned on when the sander is plugged into it.

They also have foot switching gadgets for turning on and off equipment. This had nothing to do with dust collection and has a lot to do about safety, but I loved this kick-start/stop idea–I’d rather not bend over to operate any switch or blast gate.

All these systems, variations and plans are available on the market through most woodworking suppliers. A great book to help is Dust Control Made Simple by Sandor Nagyszalanczy

All these systems, variations and plans are available on the market through most woodworking suppliers. A great book to help is Dust Control Made Simple by Sandor Nagyszalanczy

As I get older and wiser I am more aware of health concerns. I plan on incorporating these systems and approach into my own life. (I recently moved to the New York Finger Lakes Region.) With an opportunity to start from scratch with my new shop, this trip was serendipitous, and having a vacuum system that is easy to access and use will make my life easier and hopefully last longer.

I applaud and thank my new Brazilian woodworking friends for another look at how I handle dust, and I look forward to making some cleaner changes. Ciao for now.

Comments

Or you could use hand tools more often... (Backs away, slowly)

I was under the impression, from what I've heard and read recently, that the fire/explosion hazard from static buildup isn't actually an issue. I could be wrong of course and would like to see some data on either side.

Anecdotally, the only fire I've ever witnessed in a DC system was caused by a small clump of shavings hung ON a copper wire inside the duct. Someone hit a nail on a machine directly under the connection and the spark immediately ignited the shavings. One more reason to have a charged extinguisher handy.

I do love those homemade blast gates though.

As someone who will be building a new shop in the next year this article will sure come in handy. Now if only I could figure out a way to visit as many foreign shops as possible especially in tropical climates!

I have read the research papers done by the fire safety association concerning combustion and grounding of dust collection systems. According to their research, what causes combustion is pieces of metal getting into the system, hitting the impellers, creating a spark that then ignites the dust. For this reason they recommend that no floor sweeps be used. Other than keeping metal out of your dust collection unit, there is no risk of explosions except in systems with tubing greater than 13 inches in diameter.

Please give the name of this Brazilian workshop and location. Thanks.

If you want to read an article on current detection control of your dust collector, the Fine Woodworking on Small Woodworking Shops book as an article on it. The part numbers have probably changed by now, but the sources are still good.

I built one for my shop and it has greatly reduced the hassle of turning the dust collector on and off. I have it set up for my tablesaw, bandsaw, drill press and several switched outlets around the shop.

Log in or create an account to post a comment.

Sign up Log in