Powerful New Joint: Housed Double Tenons

Housed double tenons are strong and simple to make

Synopsis: This strong, weather-tight joint takes care of the problem of moisture wicking into the end grain of tenon shoulders on a traditional mortise-and-tenon joint. The U-joint has no exterior shoulders; its only shoulder is hidden between twin tenons and set below the surface of the mortise, so moisture is not an issue. With four tenon cheeks instead of the standard two, it has greater glue surface and greater strength. Though he originally designed it for use in outdoor chairs, its maker Brian Boggs now uses it for chairs of all kinds, and even tables.

When I began building outdoor chairs 10 years ago, I searched for a strong, weather-tight joint. The traditional mortise-and-tenon works well for interior pieces, but outdoors, moisture can wick into the end grain of the tenon shoulders, undermining the joint. I designed this U-joint, with its only shoulder hidden between twin tenons and set below the surface of the mortise, to solve the moisture issue. but I soon realized that the joint delivered a bundle of other benefits. with four wide tenon cheeks instead of the standard two, it had far greater glue surface, and so greater strength. The joint also made for a stronger rail, since there were no exterior shoulders to reduce the width and thickness of the rail at either end. And it was very well adapted to joining rails to shaped legs, since there were no external shoulders that had to be coped to fit. And while the shoulders of traditional tenons can pull away when they shrink in dry weather, reducing the joint’s rack-resistance, the U-joint’s shoulder remains locked between two tenons. The joint succeeded so well that I also use it on indoor chairs and tables.

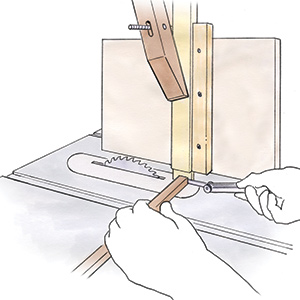

Routing twin mortises

Using a plunge router with a guide bushing and a simple plywood template, cutting the double mortise is not difficult. The U-joint mortise has three sections— the twin deep mortises and the seat between them that receives the tenon’s shoulder—but the cuts for all three are guided by the single slot in the template.

Switch on the router—with the leg blank still square, I start the mortise by milling the entire area within the guide slot to about 1⁄8 in. deep. This creates the seat for the shoulder between the tenons. I want the seat deep enough that it won’t be exposed when I shape the leg.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Leigh Super 18 Jig

Starrett 4" Double Square

Pfiel Chip Carving Knife

Log in or create an account to post a comment.

Sign up Log in