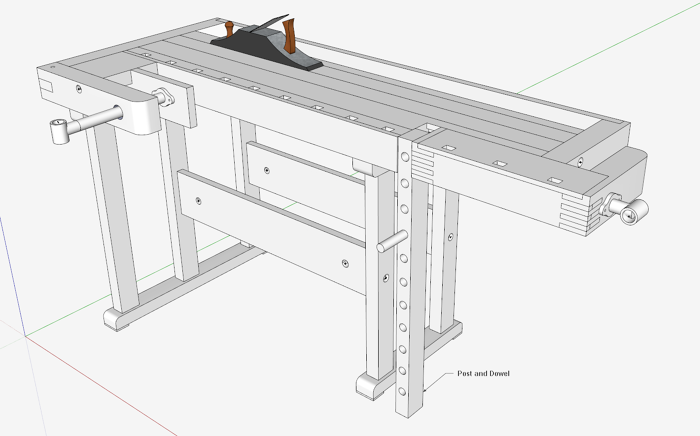

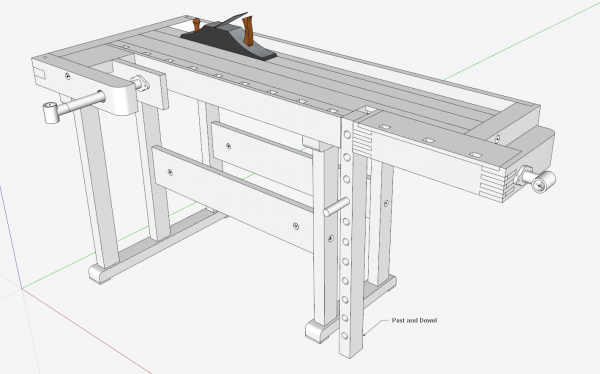

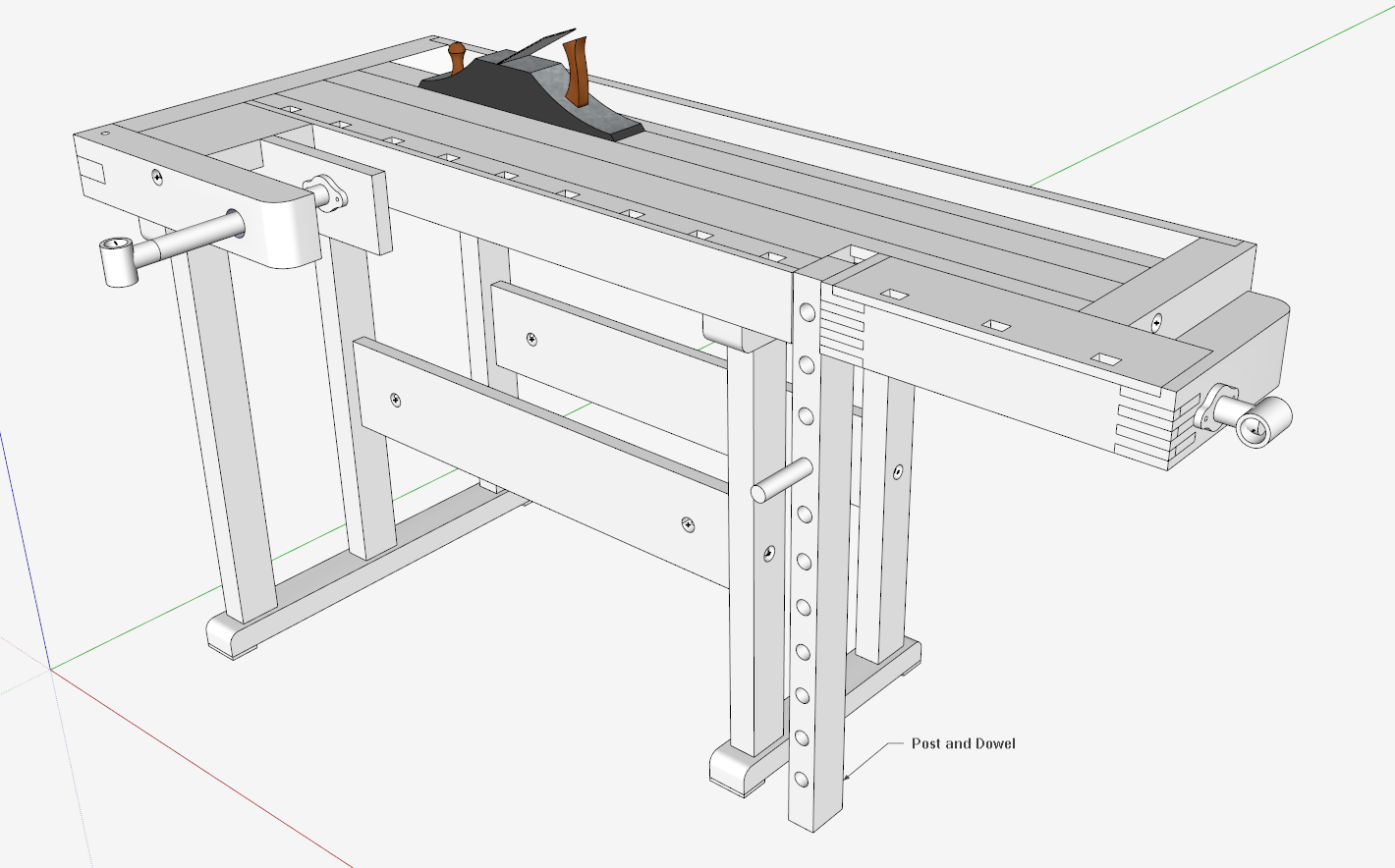

Occasionally I need to hand plane a long board and this would be an awkward procedure without a simple fixture for the workbench. It is a Post and Dowel contraption that I found in a Tage Frid publication. And in this video I re-create a similar design in SketchUp.

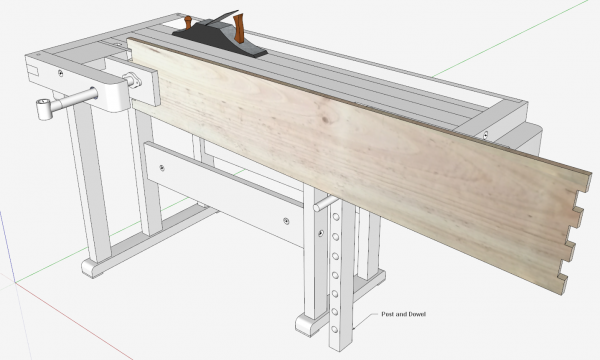

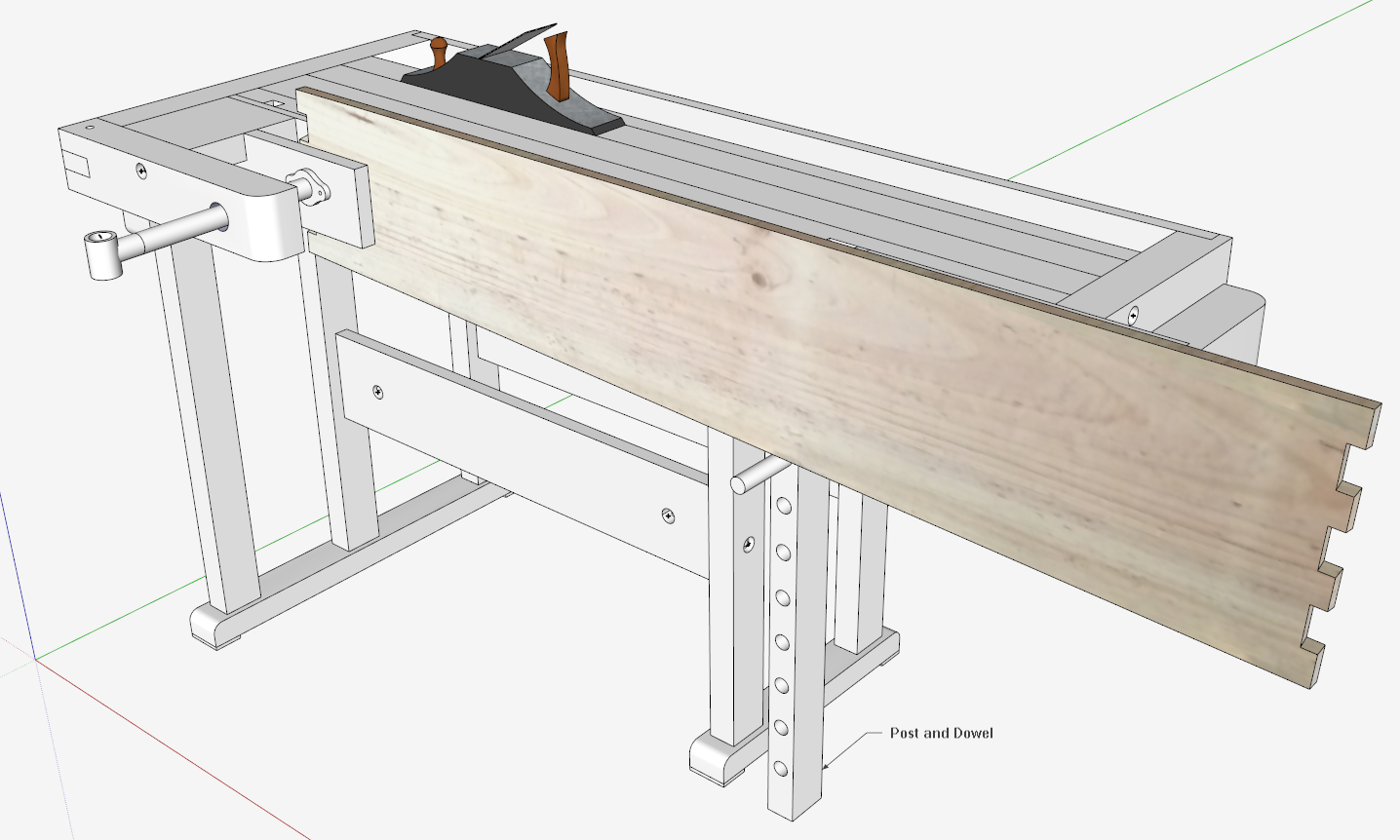

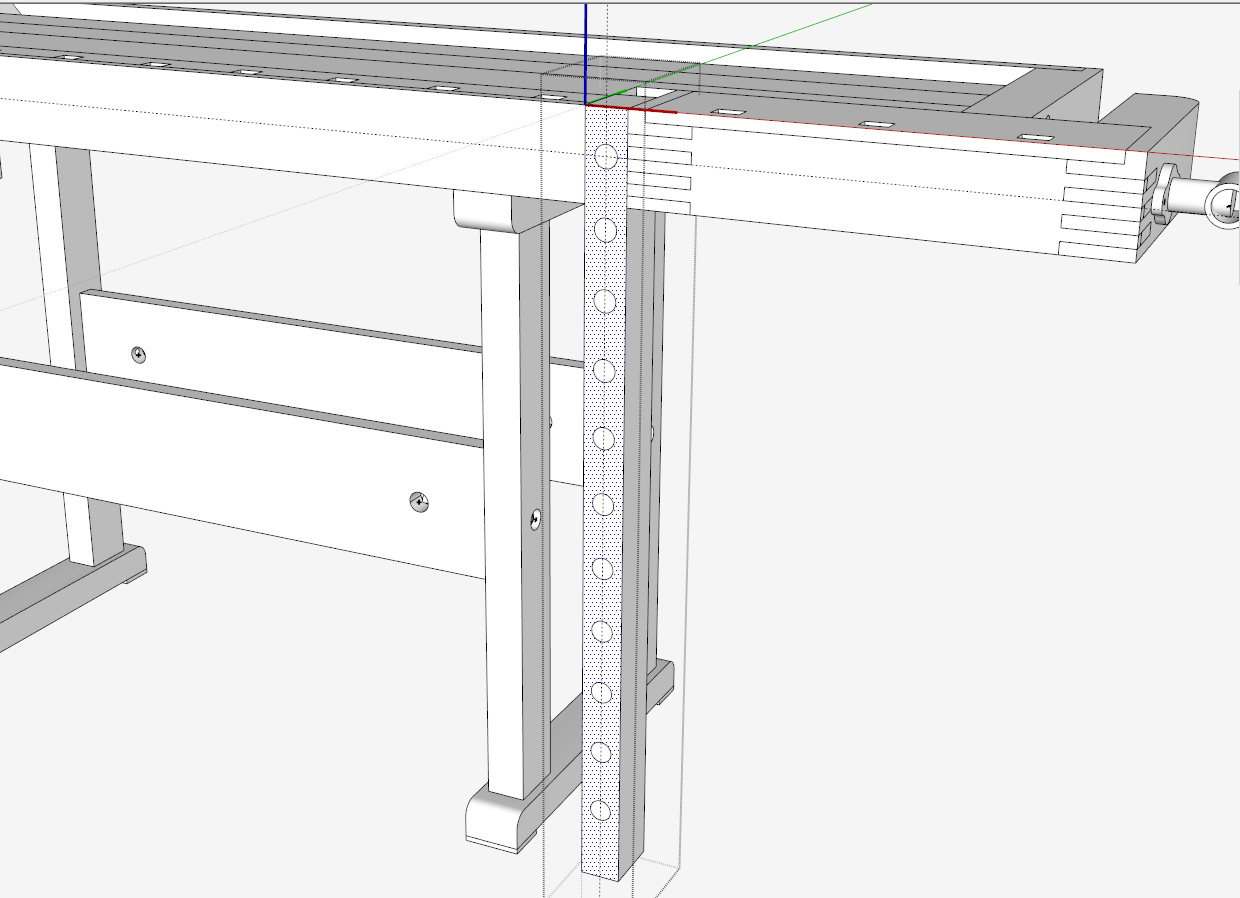

Here you can see how the long board is mounted in the workbench – clamped at the front end by the Shoulder Vice, then resting on the dowel for a firm foundation.

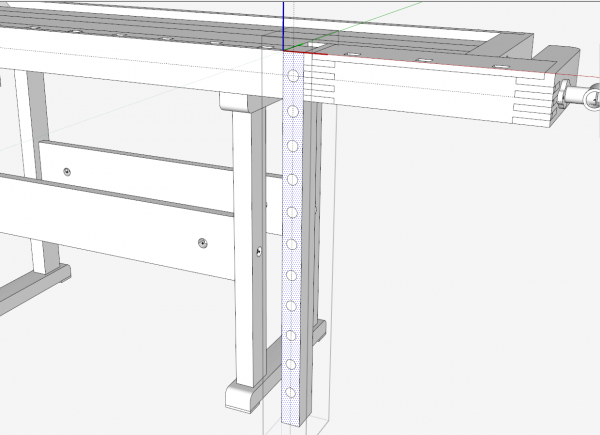

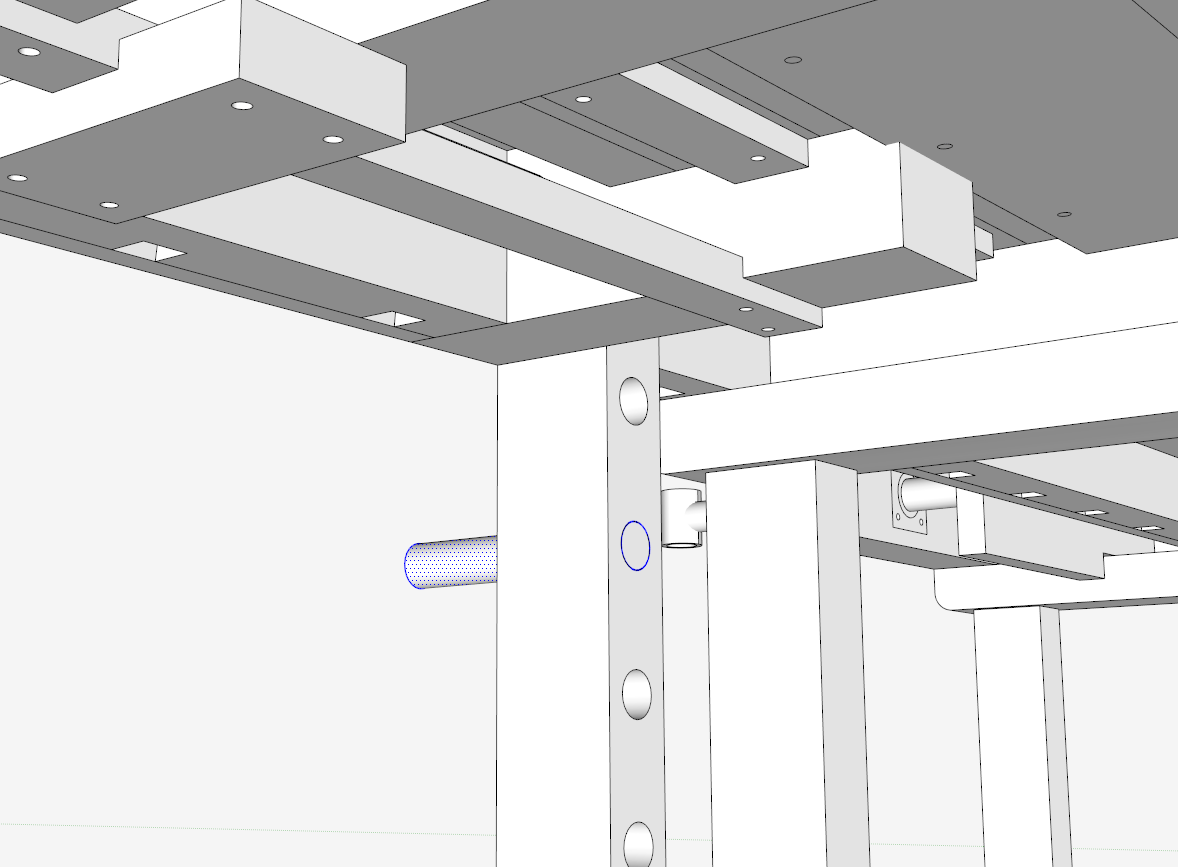

After creating the rectangular Post, the sockets are made for the dowel positioning. It is tempting to make one hole then copy to the next position, followed by an “x10” array command to complete all holes down the front face of the Post. This will work, but it causes extra tedious work. When copying the holes, the front and back faces of the Post are not “cut through”. To achieve a cut in the faces, requires close-up precise tracing over a single segment of each circle. So this must be done about 20 times for front and back faces. It works but is not as convenient as one would like.

A more efficient process is to make the first circle on the front face, copy to the next position, then perform the x10 array to complete all circles down the front face. Each copied circle does successfully “cut through” the face without having to do the tedious traceover. Each circle is then easily Push/Pulled to complete the holes.

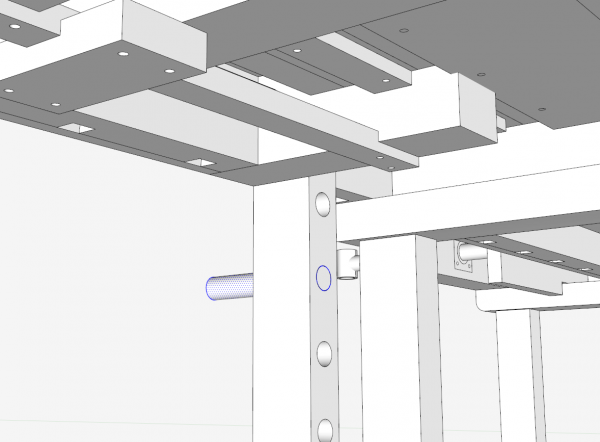

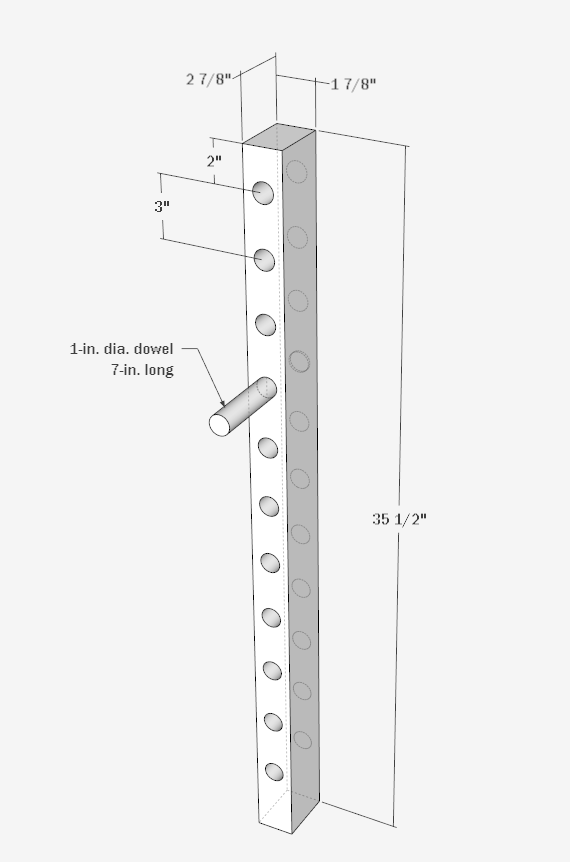

This picture shows how the copied circles cut through the face of the Post.

The last procedure is to make the dowel using the Circle and Push/Pull Tool.

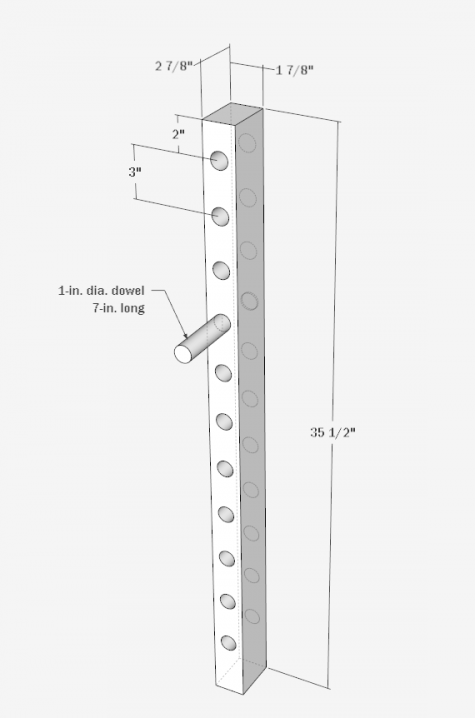

Here is the dimensioned design I am using.

And the video……

https://youtube.com/watch?v=4t0PKAb_f_E%3Flist%3DUU1pIa0qnoERn5zoFytwoA_Q

Tim

http://killenwood.com

Comments

I like this, and I think it could be expanded on by increasing the size of the adjacent table leg and having holes bored into it, rather than having to clamp an auxiliary "story pole". Kill two birds w/ one stone.

Log in or create an account to post a comment.

Sign up Log in