Q:

My mortiser’s hollow-chisel bit always heats up and burns the wood, even though I keep it sharp and clean. What can I do to avoid this?

Mitch Barnett, Columbus, MS

A:

I’ve seen this happen a lot while teaching woodworking classes. The problem with hollow-chisel bits is that the inside of the chisel is a little rough, so the chips don’t flow through easily, which increases friction and heat. The remedy is to polish this inner surface by making a little drill-mounted flap sander, a trick I learned from Will Neptune. You’ll need a dowel that’s 3 in. long and thin enough to get inside the chisel. With a handsaw, cut a thin kerf about halfway down its length and chuck the other end into a portable drill. Slip a small piece of P220- or P320-grit wet-or-dry sandpaper through the kerf and wrap it around the dowel. Insert your new flap sander into the end of the hollow chisel and polish the roughness away, working up through P400- to P600-grit paper. It also helps to polish the flutes of the drill bit. Use a stiff buffing wheel charged with jeweler’s rouge, and make sure not to polish the cutting tip. To finish the job, rub a little paraffin wax on the flutes to help the chips eject.

Keep your mortiser cool. The mortising machine works best when the hollow-chisel bit stays cool and sharp. But excess friction inside the chisel can cause it to overheat, changing its color and losing its hardness—and if you see smoke, it’s too late. When that happens it won’t stay sharp, and produces black, burned chips and raggedy mortises. A dull bit also contributes to the problem.

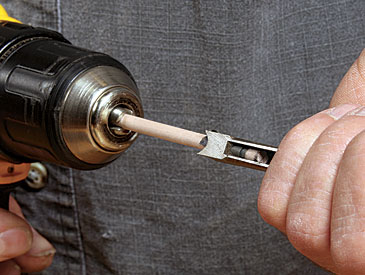

Make a custom flap sander. Cut a thin sawkerf in one end of a dowel and slip in a piece of fine-grit sandpaper. Chuck the dowel in a drill and polish the inner surface of the hollow chisel.

Polish the bit, too. Use a cloth wheel and some buffing rouge to polish the flutes of the drill bit. Don’t polish the sharp tip.

What a difference. An overheated, burned chisel makes for rough joinery (at right in photo). The mortise on the left was cut with a tuned-up chisel and bit.

Photos: Staff

Fine Woodworking Recommended Products

Festool Rotex FEQ-Plus Random Orbital Sander

Starrett 12-in. combination square

Rikon 10-3061 10-in. Deluxe Bandsaw

The saw has two speeds: 3,280 sfpm (surface feet per minute) for wood and 1,515 sfpm for soft metals and some plastics.

Comments

What type of chip removal system do you have? Tom Casper, American Woodworker, had a similar problem until he adapted a vacuum to remove the chips. While a sharper chisel and a better chisel set up will help, the vacuum will enhance what you have already done to prevent the burning.

Log in or create an account to post a comment.

Sign up Log in