Easy levelers for shop work stands

Most shop floors will require you to individually adjust one or more of the feet to remove wobble and also level the stand with whatever machine you are using. On the original stand you have to bend over and reach below the base to spin the foot.

We were about halfway through the photo shoot for Michael Fortune’s awesome work-support stand in FWW #244 (Tools & Shops), when he said. “By the way, there is a wonderful improvement I always meant to make to this stand,” he said. Nice timing, Michael!

Unfortunately, the project was too far along at that point, and we didn’t end up having room in the article anyway. So I promised Michael we would do it as a free online extra.

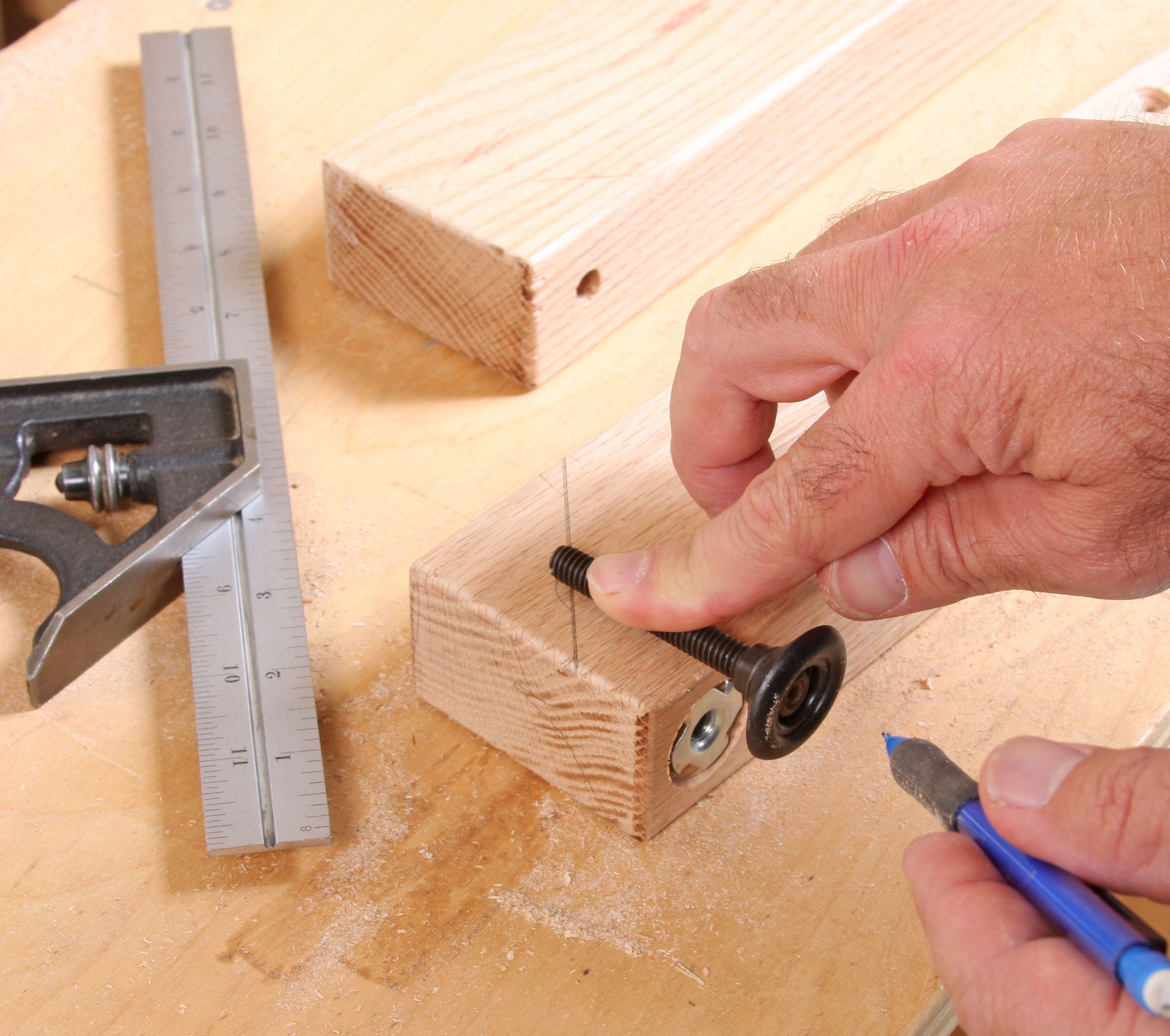

Here it is: Simply by making a big bevel cut at each corner of the base, and hacksawing a small slot in the top of the bolt for each adjustable foot, you can make the feet adjustable from above with a screwdriver. Otherwise you have to bend over farther and twist the bottom of each foot by hand.

The pictures show how easy it is. It’s cool how the hacksaw blade creates a screwdriver slot. To learn how to build this rock-solid, smooth adjusting support stand, read the full article.

Comments

Nice addition. But why the bevel? Unless I miss something, it seems to me if you just drill a pilot hole for the stem of the screw such that your adjustment screw-driver will fit you don't have to futz around with keeping the screwdriver on the end of the screw. Adjustment becomes - insert the screwdriver, turn gently till engaged in the slot, and turn to adjust.

What say you?

Regards -

Rob

Great idea RoBanJo! Just wish I thought of it.

I agree with RoBanJo on the advantages of keeping the foot's stem housed in a hole in the wood. Exposing the end of the stem with a bevel cut, as shown in the photo, risks snagging power cords, vacuum hoses, shoelaces, trouser cuffs, and anything else that might drape or drag across it.

Eliminating the bevel might mean that you have to vacuum sawdust out of the hole now and then, but that seems like the better option to me.

The method I use to slot screws is to use a find cutoff wheel on a Dremel. It cuts the perfect size slot in the end and if you are careful produces a nice even slot. You can also use this same technique to freshen the slots of screws that have torqued out.

Log in or create an account to post a comment.

Sign up Log in