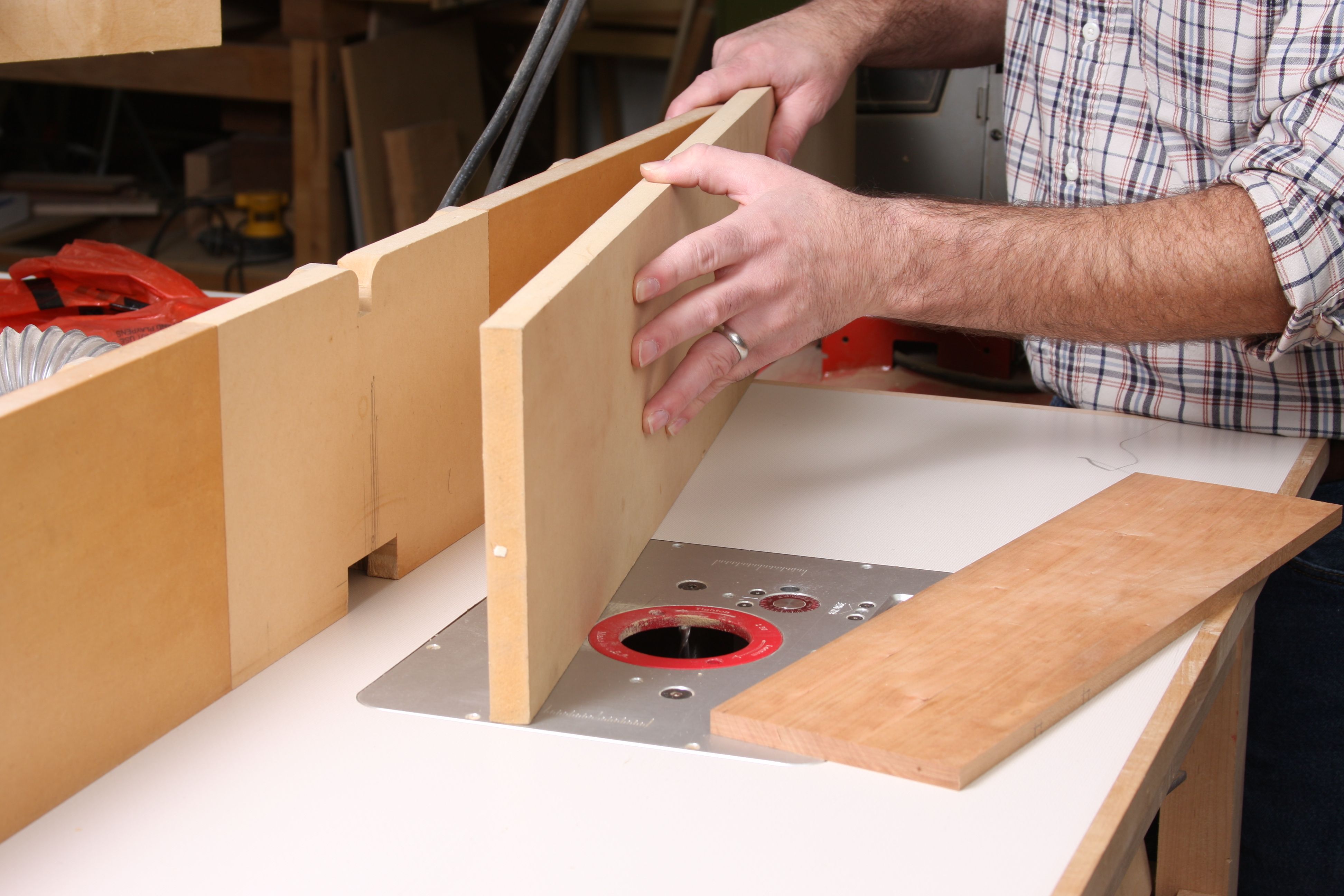

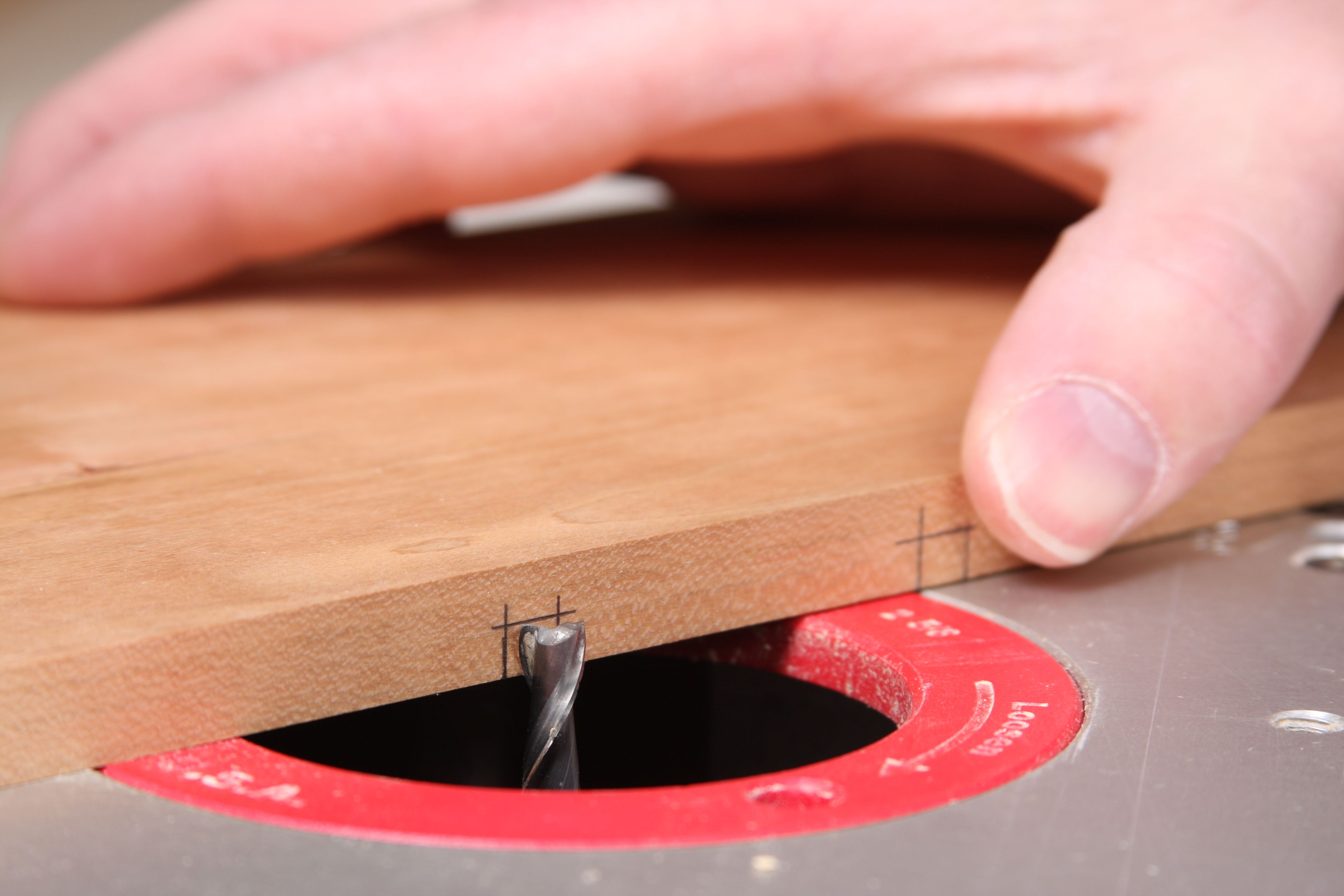

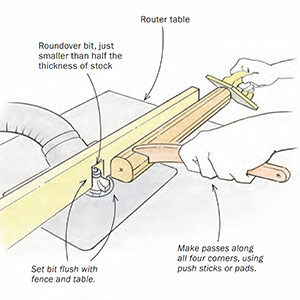

Add an auxiliary face to your fence. It serves two purposes. First, it covers up the hole in the fence, so that your workpieces don't dip into the hole and ruin the cut. Second, you'll be able to mark on the fence where the bit begins and ends. You'll see why that's important after a few more photos.

I make a lot of small cabinets with lots of drawers. That means I end up needing a lot of drawer dividers to create the pockets. Because the cabinets are small, I use solid panels for the divders, and house them in stopped dadoes cut into the cabinet sides. For a long time, I struggled with these dadoes. I used to cut them with a handheld router and a T-square style guide. I always had two problems. First, even though I laid out both dadoes in a pair at the same time, when I routed them they never came out aligned. When I put the divider into the dadoes, it would slop down toward one side of the other, and my pocket wouldn’t be square. Second, I often ended up with dadoes that weren’t sqare to the front edge of the cabinet, so the drawer divider would slope up or down as it went back. Another bad drawer pocket. I also hated how difficult it was to clamp the guide to the workpiece and the workpiece to the bench. It seemed that at least one clamp always impeded the router’s travel.

I solved those problems when I switched from a handheld router to the router table. By referencing the end of the cabinet side off of the fence for the dadoes in both sides, I am guaranteed to get dadoes that are square to the front edge and aligned with one another. The result? Wonderfully square drawer pockets, which means that it’s much easier to make and fit the drawers. (One note: In order for this technique to work, the end of the cabinet registered against the fence must be square to the edges of the side. But, really, it should be square no matter what.)

Take a look at the photos to see how I set up my router table to cut the stopped dadoes.

Comments

Or you make yourself a dado jig for your handheld. Make it square and fit a collar on the router to run along it. You put both boards together flush and square and mark them together like for a biscuit. Then you align your jig to the marks and hey presto! they are aligned.

My jig has a moveable arm for different width dadoes and I can cut sliding dovetails with it with two routers (the one from the table added), one with the straight cutter and one sized collar to rout the relief and then the other with the dovetail cutter to finish off with, down one side and up the other.

I have cut any number of stopped, including double stopped, dadoes with it that come out square and parallel every time. I made it from offcuts with a hardwood stock and plywood arms. Waxed plywood arms.

Great idea, but incomplete. The description calls for only a single mark on the fence, but the photos show two. It appears that a mark must be made on the fence that corresponds to both sides of the bit in order to assure the cut stops at the correct location.

come on guys this is old hat stuff. a better way is to use a mechanical stop clamped to your fence for dead on accuracy and most important use a sled for safety. I can't believe anyone would consider making a cut like this without a backer board and a clamp. Lowering a board into a spinning bit without support. '' WOW ''

I agree with Grumpy66. Has this guy still got all his fingers?

I only have 7 fingers, but that's all I was born with.

Log in or create an account to post a comment.

Sign up Log in