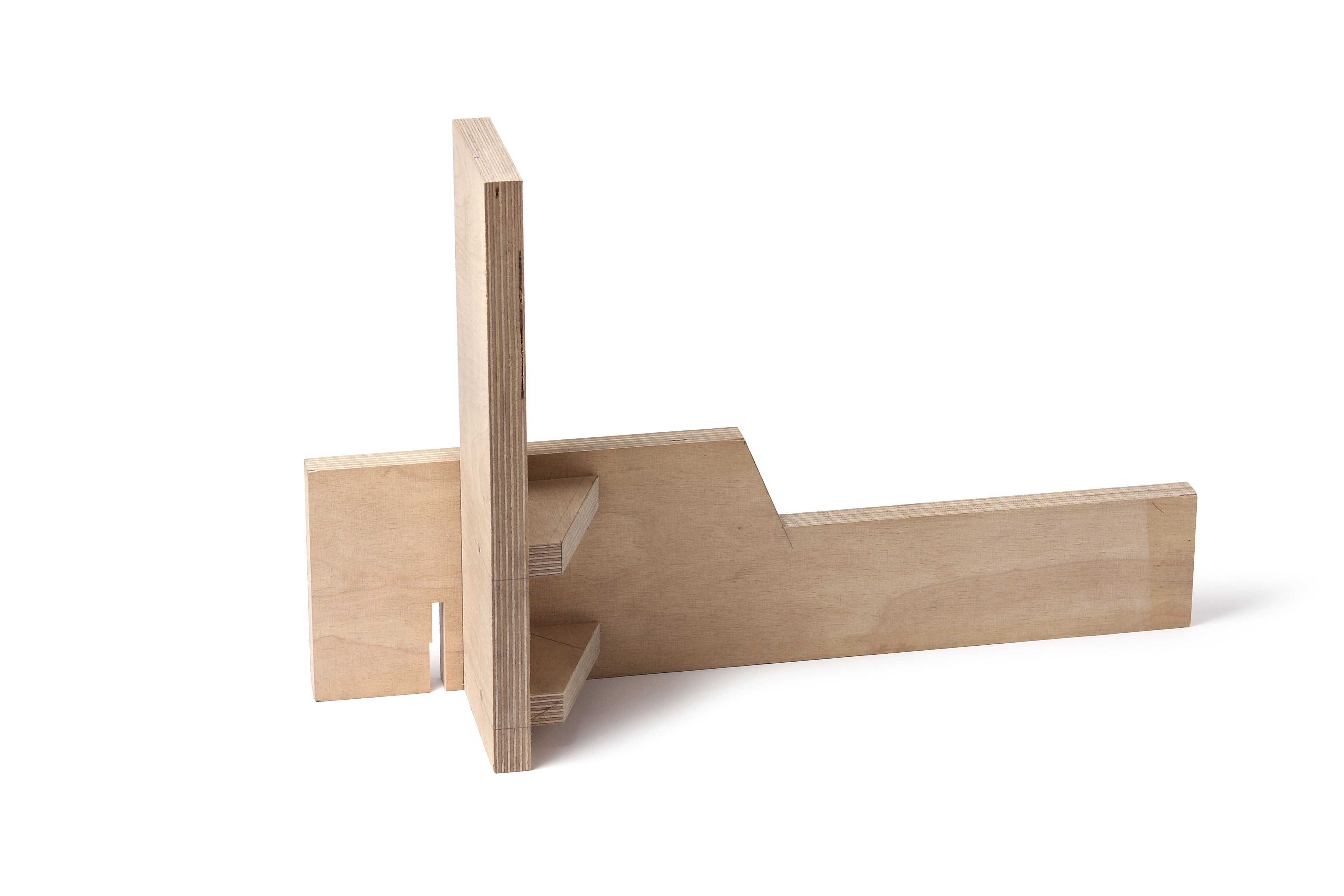

Keep it simple. This tenoning jig, which clamps to a miter gauge fence, does everything it needs to without any fiddly knobs and adjustments.

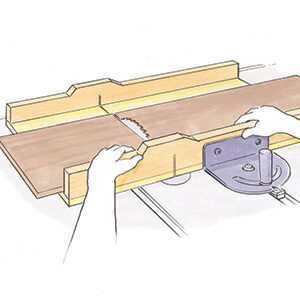

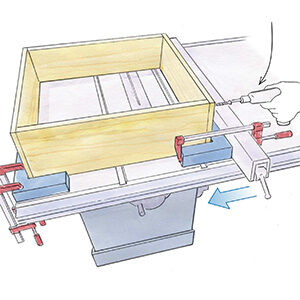

When it comes to jigs, I’m all for keeping it simple and making it fast. So, when I needed a tenoning jig (I actually used it to cut some bridle joints), I sat down and thought about it for awhile, trying to come up with a design that I could make quickly (and still have it be a good jig) and that wasn’t overly complicated. The pictures above show what I came up with. It has just four parts. The back fence attaches to my miter gauge (clamps). The vertical support is screwed to the back fence and kept square by two little triangular supports that a screwed to the fence and the vertical support. It took me about 1/2 hour to make. Not too bad. When the back fence becomes too cut up, I’ll just screw on a piece of 1/8-in.-thick hardboard, which itself can be replaced, too.

Comments

Straightforward, accurate and reliable. I like it!

Well done.

Problem is, a steel tenon jig can be had for 90 bucks or less - if you shop around - it is very precise and will last forever...

not knocking the design cuz I haven't tried it, but whats the advantage of this over a "on-the-fence" style tennoning jig. From what I've seen, they look much simpler to construct. Again, just curious, not critical.

Log in or create an account to post a comment.

Sign up Log in