The Weirdest Handplane I’ve Ever Used

Planing a bead into these two pine boards was easy with my well-tuned Stanley No. 55.

If you consider yourself a hand tool junkie, you’ve probably heard of the Stanley No. 55 “universal plane.” Manufactured between 1897 and 1962, the No. 55 was marketed as “a planing mill in itself.” In a nutshell, this oddball tool is to woodworking what Swiss Army is to knives. It does just about everything-from dadoes and rabbets, to moldings and tongue and groove joints. Thanks to the plane’s army of profiled cutters (the kit originally came with 55 different irons), you can combine an endless array of hollows, rounds, beads and more–to match moldings in the field. By the time the 55 came around, architectural moldings were already being mass produced by mills, but a carpenter on the jobsite needing to match some baseboard or door casing on the spot could-theoretically-reproduce a short run of just about any molding in a pinch. A neat idea, but a potential headache in reality.

On a recent visit to my neighborhood antique/junk shop I happened across an old 55 in its original chestnut box (which means this is one of the earliest models), complete with all 55 irons, and the complete compliment of accoutrements that leave most woodworkers scratching their heads when they first lay their eyes on this marvel of engineering. All this for 20 bucks. Mind you, my colleague Matt Kenney remarked: “that’s $20 too much!” Matt likes to be snarky.

After disassembling the tool I gave it a good scrub-down with degreaser, applied some new paste wax to the rosewood fences, and re-honed a few of the irons. I’ve not experienced any trouble pulling beautiful beads and forming perfect tongue-and-groove joints, and I can understand why some folks give up trying to produce shavings with this tool after only a few hours. Truth-be-told, the No. 55 looks more complex than it really is. All of those turn screws you see poking out from every direction are merely there to hold down the various fences and “skates” that make up the tool. And once you take the time to read the original manual, and try your hand at planing some scrap wood with it, you’ll soon learn that the 55 is a joy to use. I’ve had good success planing pine, cherry, and walnut. The key is understanding how to set the plane up for success. Here are a few tips.

Planing Beads with a Stanley No. 55

Sharpen the Iron

Step one is obvious. The iron needs to be sharp, with a nicely polished back. I had to re-flatten the backs of some of my irons using sandpaper in various grits. Then I switched to waterstones until I achieved a nice polish. Only then was I able to hone the bevel. The main bevel was easy to hone freehand on a stone. When it came time to hone the convex portion, I wrapped some 320, and then 400-grit sandpaper around an appropriately sized dowel and got to work. Then, just as with any tool blade, I flipped the iron over and lapped away the burr formed on the back using my finest stone.

A Dab of Paste Wax

It’s common to wax the sole of a plane for smoother sailing. In the case of the 55, it doesn’t really have a sole on the bottom-the bearing surfaces are the narrow edges of the “skates” and the rosewood fences, so take a moment to give them a nice bit of paste wax for easier handplaning.

Adjust the Skates

Located in between the two rosewood fences are the “skates.” Aptly named because of their shape, the skates should be aligned with the edges of the bead cutter. You’ll use 4 of those 326 hold-down screws to lock the skates in place [sarcasm].

Bring in One Fence

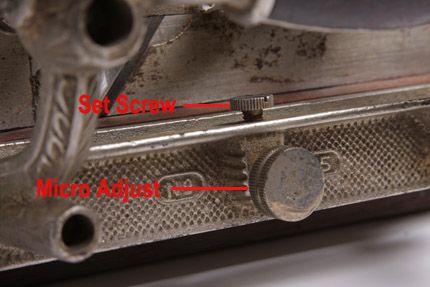

To cut a bead along the edge of a workpiece, I only need one fence. Just be sure to set it in such a way that it covers one of the two fillets on the bead cutter. The fillets form what’s called the “quirk” in a bead. You only need one quirk, so cover up that second one. You can slide the fence in along the two steel dowels for a macro adjustment. To micro adjust the fence’s position, Stanley provided a nice dial and set screw. Works like a dream!

Cut Your Bead

Fix your board to your bench with the grain running in the proper direction and set the plane atop your workpiece, registering the fence against the board’s edge. Hold the tote with your dominant hand (right, in my case) and grab the rosewood handle attached to the fence with your left hand. You want to rely on the weight of the plane to do the work and push using your right (tote) hand only. The left hand is there merely to add a bit of lateral stability as you work your way down the board. I’ve found that one of the keys to using the 55 is a soft touch. If you bear down on the tool, it’s going to cause tearout.

And there you have it, a nice, well-formed bead. Granted, I’ll probably never use half of the irons that came with this tool but that’s alright. I plan on hitting the road with my 55 and building some small furniture pieces at the local farmer’s market where I sell my wares. Folks always get a kick out of seeing this crazy contraption in action, and from my end, I can’t help but love the fact that I’m building furniture with the aid of a tool that was cared for and used, at around the time when Theodore Roosevelt was president. If only this tool could talk.

Comments

I remember drooling over ads for this plane when I was a kid in the late 50's, early 60's, when you could still buy them new. I thought they were way cool!

Deal of the century!

$20? Wow! I'd have paid 5X times that on the spot without even thinking about it, and 10X if the thing was in good shape in its original box. Love those beauties.

I have a 45 with all irons, sharp and properly setup they are sweet to use.

I have both the 55, and its little brother the 45, and I use them both.

Wish I could have found one for $20.00, sweet !

Where's the USB port?

If this plane could talk, it would simply ask "why have I been alone in a box for a century?"

I salvaged my 45 from a dump run when i was helping a relative was clean out a basement. No one (including me) knew what it was but it looked too good to go to the dump so i took it home. later i found a pamphlet about it and it became my primary tool (after a saw) to make my first bookcase. 50 years later i still use it.

As the kids like to text; "OMG", in the original box, all or most of the cutters, and not rusted out????? "$20.00".

I hope you slapped Matt silly!!!

Most of these sat in boxes unused because they were advertised as a panacea, an average Joe could make anything his heart desired. After selecting the cutters and honing the irons and carefully setting all the skates depth stops and nickers the user then tried working right to left with the lightest touch because the damned contraption would dig in and jam then the got put away in their box and left for us to buy in a junk shop for $20. Of course with the benefit of the internet I know what my Dad an enthusiastic DIY guy never found out you work it left to right (gentle touch not required) until almost full depth then do the final pass right to left. Who knew!

I remember my dear old Dad, many years ago in my childhood (1950s) who did amazing things with this plane. He also had a similar device from Switzerland if I recall correctly. These along with the odd routing types of plane he used to great effect in his work. For me myself, I have not see one since but would love to get my hands on a full set. Problem is that here Down Under there are not many places one could locate one. Once day maybe. All the best guys and keep up the good work. Yes, I am Brian_Patmore (Tasmanian Devil stock and with many cousins in the US of A and Canada from my great great uncles Joshua and James Richard Patmore back in the 1850s when seven Patmore brothers travelled the world looking for a new home when their parents died at New Havers Farm, near Newtown in Essex - they were Scot extraction apparently.)

Mr. Pirnik hasn't even scratched the surface for what it takes to use one of these contraptions. Patrick Leach said it best in his assessment of the Stanley 55: "We should all be so lucky to be chained to a rock and have our livers eaten daily by an organ-hungry raptor than to suffer the agony of this contraption."

Having said that, twenty dollars is a steal because 55's are still fetching a very good price on Ebay. Which is where mine would be except that I inherited mine from my Great Uncle who was a contractor back in the day. For that reason I feel obligated to hang on to it, but I'm certain my kids will sell it after I'm gone.:)

They work well as an extra plow plane when needed.

How big is the throat, and how do you close it? The 45 and 55 both had the same problem regulating the cut. Too often the new owner had no idea why it didn't work as advertised, so it went back in the box. A treasure for tool junkies, a bane for tool users.

They are both as much work to use on figured wood as is needed to make your own wooden plane with the same iron.

I have both a 45 and 55, use both of them to reproduce missing or damaged mouldings in my early 18th century home. With practice (this is key) these contraptions are fun to use. But you gotta-wanna do it enough to spend the time and endure a little frustration along the way. Pay attention to grain direction and go easy. Rub a little paraffin on the skates and fence and depth stops. And, practice,practice....

I am amazed at the good condition and availability of these planes. As has been pointed out frustration led to many a Stanley 55 being relegated to the back of tool shelves. However, $20 has got to be the deal of the year!

Chuckh: I love the way Patrick Leach writes. When I first read his missive on the 55, I nearly squirt coffee through my nose -- I laughed so hard. There is certainly some truth there.

I'm not sure that I'll ever use the plane to make "full-on" moldings. I enjoy cutting a variety of simple beads with it, tongue and groove joinery, but I'm not sold on the idea of making all sorts of custom moldings--although i do plan on trying it out for this purpose.

never-the-less, this is a fun tool to use. As was echoed by other commenters here -- it seems that these tools are often in great shape because nobody ever took the time to really master the tool.

Cheers.

Ed

Oh, and there is no real "throat" or way to adjust it -- one of the tool's short-comings. But it still gets the job done, provided a sharp iron and a light touch, coupled with straight-grained wood that isn't too tough.

At least that's been my experience.

E

Ed

As I mentioned, I inherited my 55 from my Great Uncle who was a very skilled craftsman and built homes when they did most of the millwork on site. On this plane the fences show wear but very few of the blades show any wear. Only the grooving blades and a couple of the beads. So even he must have quickly learned the frustration and limitations of this tool.

As for me, I will never sell my Stanley 55, but I will continue working on my collection of Hollows and Rounds.

-Chuck

I have a Stanley 55, as well as a couple of 45's. They're a bear to set up, but with a lot of practice, they work great.

If you want to see an expert using a 55, as well as 45's in comparison to wooden molding planes, watch The Woodwright's Shop at PBS.org.

In a 2013-14 Season Episode, Roy Underhill demystifies some of the 55's quirks (pun intended), and in his always entertaining fashion, manages to keep a jumble of tools from falling off his bench while demonstrating important hand tool skills.

I have a 45 and it looks great as a novelty piece on my coffee table; but would someone answer this; If the 45 and 55 are so great why doesn't someone still manufacture them? If they are that good there would be a "woodworker" demand and not just a "collector" demand.

I really enjoy mine, all shinny and displayed on a nice piece of walnut; it is a great conversation piece.

But putting nostalgia aside; is there really a place for these two beauties in the modern shop?

Thank you for sharing this blog if you want to buy any hand tool than visit - global sparenparts private limited

Okay, there was a replica/reproduction made within the last 30 years. It came in a wooden box, perhaps mahogany. According to the extremely short instruction booklet, "The Paragon Multi-Plane has been commissioned by Garrett-Wade of USA and Lee Valley Tools of Canada to ensure that this classic and traditional tool does not become extinct." I like that. Made in Sheffield, England. The booklet is fine print, only 5 pages of instructions (Including drawings). Date on booklet = Nov 1984. Crude enough that it almost looks like a copy from a century ago. Not sure how many blades, but they are in two plastic roll packs. It says that the special boxes and cutters (Hollows & Rounds) in the booklet are included for authenticity & completeness, and aren't offered under the Paragon brand. The "standard" set has 24, the "additional" set has 16. For the cutters not included, they suggest the second-hand market for Multi-Planes, they believe those cutters are compatible, but can't warranty it. The Paragon did NOT cost $20.00. Is it still made? It is the devil to get the hang of, but once you get it working, it is actually comfortable. The first trim it made went up in a house fire.

Log in or create an account to post a comment.

Sign up Log in