3-D printers can now print wood

This basket was created by a 3-D printer, using a wood-plastic mix. It would have been extremely difficult to make in solid wood, not to mention fragile.

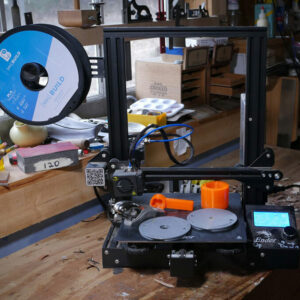

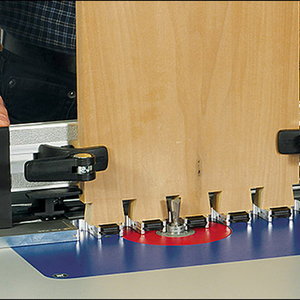

First it was CNC routers churning out stacks of identical parts, with smooth curves and precise joinery. See Scott Grove’s recent blog for a fantastic discussion on the repercussions of technology for the craft of fine furniture-making. Soon after CNC, CAD and 3-D rendering programs stepped into to make design quick and easy. Most recently, engineers figured out a way to “print” those 3-D designs, using a jet of molten plastic, laid down in tiny beads. As with pixels, the finer the bead, the finer the resolution/detail of the result.

This new era of rapid-prototyping has revolutionized the industrial-design process, replacing (unfortunately) a generation of skilled modelmakers, but also making it much faster and easier to bring new products to market and improve existing ones.

If you consider these new technologies a threat to our craft, you’ll be even more worried about the latest development. New wood-plastic composites are allowing 3-D printers to churn out objects that look at least something like wood, including a grain pattern of sorts (a byproduct of the printing process).

What is most amazing about 3-D printing is that it is additive in nature, meaning it is created by addition, without the waste involved in harvesting chunks of trees and creating sawdust until a functional object emerges. Also, the new wood-plastic composite can make use of low-cost wood waste from traditional manufacturing.

One startup company is taking advantage of the technology to offer entire furniture pieces. Their process is different, using a binder to stick many small pieces of wood together, but it is still additive in nature. The company needs to hone its furniture design chops, but I’m sure they’ll add that skill set before long.

Comments

Glad to see it - just like any tool it broadens the scope of what is possible. Just like it has done with plastics and metalwork, it'll be interesting to see how people use the additive nature of the technique in ways that are much more difficult to achieve with subtraction methods.

Poor journalism because the title is misleading. This is not 3-d printing of wood. The material is plastic with wood fiber additives. There are real advantages to this technology such as rapid prototyping and cheap manufacturing. Don't confuse these with claims about printing wood.

The advent of a 3D printing will not replace a generation of modelmakers- every other kid in town is using the 3D printer at the public library, and our local YMCA just replaced the game room a media lounge with its own 3Dprinter.

And, how about a mention of the strength of that material? Does it break along the "grain"? Are those plastic brackets as strong as a wood joint?

That bench looks okay, but up close it probably has the feel and appeal of your basic recycled milk carton bench.

The exciting thing about the advent of this kind of technology is watching how creative minds find new ways to put it to use.

Yup this is actually pretty cool. What I would have mentioned in this article though is this special kind of material is known as a 'wood filament'. Some of these filament based 3D printers actually use 'real wood' in their filaments. Would I consider this technology a threat though? Not by a long shot. Yeah maybe you can 3d print stuff now that any type of wood can produce such as this wooden barrel: https://pinshape.com/items/20767-3d-printed-wooden-barrel-wine-rundlet but nobody is replacing real wood anytime soon :) - I feel this a great of helping other people enjoy wood working even more.

Log in or create an account to post a comment.

Sign up Log in