Sharpen Your Own Hybrid Drill Bits

Furniture maker Michael Fortune demonstrates his homegrown method for sharpening a hybrid twist drill bitOntario furniture maker Michael Fortune is known as a wizard of wood bending. He’s also respected as an all-around ingenious woodworker when it comes to practical tips and tricks in the workshop.

Case in point: Fortune argues that the standard brad point drill bits commonly used by woodworkers actually suffer from a flawed design. These expensive bits have a scoring cutter along either side of the central point. These cutters heat up during the drilling process, leading to ever-so-slightly misshapen bits that eventually leave ragged holes of odd sizes. In addition to that, the central points on these bits tend to be much longer than need-be.

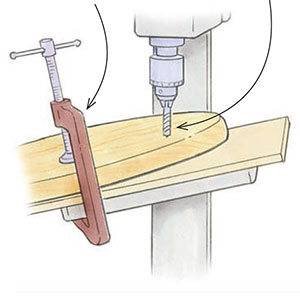

Instead of brad point bits, Fortune transforms his garden variety twist drill bits into high performance drill bits that perform better than their pricier brad point brothers.

Comments

It looks like you start w/ a regular twist bit, but once you start grinding it looks like the bit suddenly is a BRAD point bit. Did you leave out some major grinding that turned it into a brad point bit, or swap bits mid video? Since the work is so fine/small and precision, it's difficult to really see the exact strategy in this video. Some companion diagrams blown up, with detailed instruction as to the portion to be removed, angles, etc. would really make this as useful as intended. Thanks...

I think the brad point is created as part of the grinding along the edge of the wheel, although it's hard to see clearly. I second your suggestion of providing diagrams and drawings of the bit before and after each step so it is clearer than a video to see what is going on. I is especially unclear to me what is meant by the "gullet" and how that makes the bit the correct size.

Mike (et.al) - possibly one of the best videos I have ever seen. Your communication is impeccable. I can now TEACH others.

Please do more videos!

Mark

Jeez that's a lot of work. I've experienced the brad point failure Michael refers to and to avoid it, I simple use a brad point bit to initiate the the hole and them switch to a regular bit to complete it. I also hone my brad point bits when the scoring edges dull and spread.

I have not had the failures the teacher suggests. That is, my brad point bits work just fine. I fail to understand why "the brad points are too long". What's the problem with that? They make it especially easy to get the point into the exact spot and have no drawbacks I can see.

This all seems like too much work for little gain. At least for me. And to make a complete set? Wow, that's a huge amount of time and effort and I certainly don't have a complete set of throwaway bits hanging around.

Lastly I'd like to see him doing this on a 3/16" bit!! And smaller ones!

So sorry, but I don't see value in this technique. But keep 'em coming, most videos are helpful.

I agree with fatdogearl and dirkfaegre. If a wing forms on the scoring edge, grind it down and dress it up. What harm is a point "too long?" It centers the drill more precisely.

Don't know how I missed this in years past but glad to see it now. I have been dressing mine by hand for years and it a tedious and time consuming process. I haven't had a problem with the point being too long. Too many are off center from the factor. I think I'm going to set up a jig for my wet grinder and try this.

Thanks Michael

Be Safe and have fun

Log in or create an account to post a comment.

Sign up Log in