Restore a Vintage Vise

Built to last and easy to refurbish, sturdy old vises are a great bargain

Synopsis: Why spend money on a new vise when you can repurpose a vintage one? As a teacher and furniture maker, Steve Latta has acquired a lot of vises through the years but says he’s never bought a new one. Good old vises with plenty of life in them are easy to find and inexpensive, and refurbishing them is fun. Just remove the rust, free any stuck parts, and apply a fresh coat of paint. You might also replace the jaw pads, handle, and benchdog. Then lubricate your new old vise and you are good to go.

I’ve acquired a lot of vises over the years—without buying new ones. good old vises with plenty of life in them are easy to find and inexpensive, and refurbishing them is actually a pleasure. Bench vises aren’t complicated—most come apart with the removal of a few pins or bolts. After that, cleanup consists of removing the rust, freeing stuck parts, and applying a fresh coat of paint. depending on their condition, you might also replace the jaw pads, handle, and benchdog. Add a little wax to lubricate the moving parts, mount it to your bench, and your new old vise is ready for many more years of service.

Buyer’s guide to vintage vises

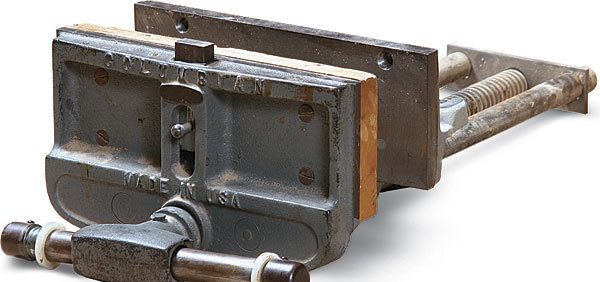

There are a lot of solid vintage vises available, so don’t compromise on features. I’d limit the search to vises that mount to the bottom of the bench with bolts. I prefer a vise with a quick-release screw, jaws that are 4 in. deep, and preferably a benchdog, too. You won’t go wrong with brand names like Abernathy, Columbian, wilton, record, and Brodhed-garrett. I’m pretty picky about the vises I buy, and I still usually get them for a steal. deals can be had for as low as $40.

Find a workhorse to revive

Made in great numbers and virtually indestructible, old bench vises are easy to find. Many shops, flea markets, and websites that sell old tools will have a selection of them.

Some favorite vises. Good options for an old vise are, from top, Wilton, Abernathy, and Columbian. Latta limits his search to vises with quick-release action and jaws 4 in. deep. A little rust or a missing handle or dog are not a problem.

Remove the handle first. A hammer and punch will usually remove the pin holding the handle head to the main screw shaft (above). A more ornery pin can be drilled out on the drill press and replaced with a roll pin at reassembly. Then completely disassemble the vise, using penetrating oil if necessary. Document the disassembly with photos to make reassembly easier (right).

Brass brush for light rust. Latta uses degreaser and a brass-bristle brush to clean the threads of the quick-release mechanism.

Renew the guide rods. After knocking off most of the rust with sandpaper, Latta rubs the guide rods with a gray, medium-grade 3M abrasive pad. He finishes the job with 000 steel wool.

For the full article, download the PDF below:

Comments

Thats my exact bench vise! Luv it!

Log in or create an account to post a comment.

Sign up Log in