Cutting the Half-Lap

Accurate layout makes sawing and paring lap joints easier.

Synopsis: A good starting point to learning the skills to cut joinery by hand are half-lap and T-lap joints. These simple joints bring home the most important lesson about hand-cut joinery: Accurate layout is a must. You’ll also get to practice cutting and paring cheeks and shoulders, two tasks involved in just about all furniture joinery.

To me, there’s nothing more satisfying than building a piece of furniture using hand-cut joinery. But cutting joinery entirely by hand can be an intimidating task. I think that’s because we tend to think of the ideal joint, one brought together with a nice friction fit and no gaps. But this ideal joint is not an insurmountable mountain. Break it down, and you realize that it’s just a series of small steps. With a bit of practice, tackling the joint one step at a time, you’ll soon become proficient.

A good starting point to learning the skills to cut joinery by hand are half-lap and T-lap joints. These simple joints bring home the most important lesson about hand-cut joinery: Accurate layout is a must. You’ll also get to practice cutting and paring cheeks and shoulders, two tasks involved in just about all furniture joinery. Once I show you the secrets to these basic joints, you can apply the skills to more complicated ones.

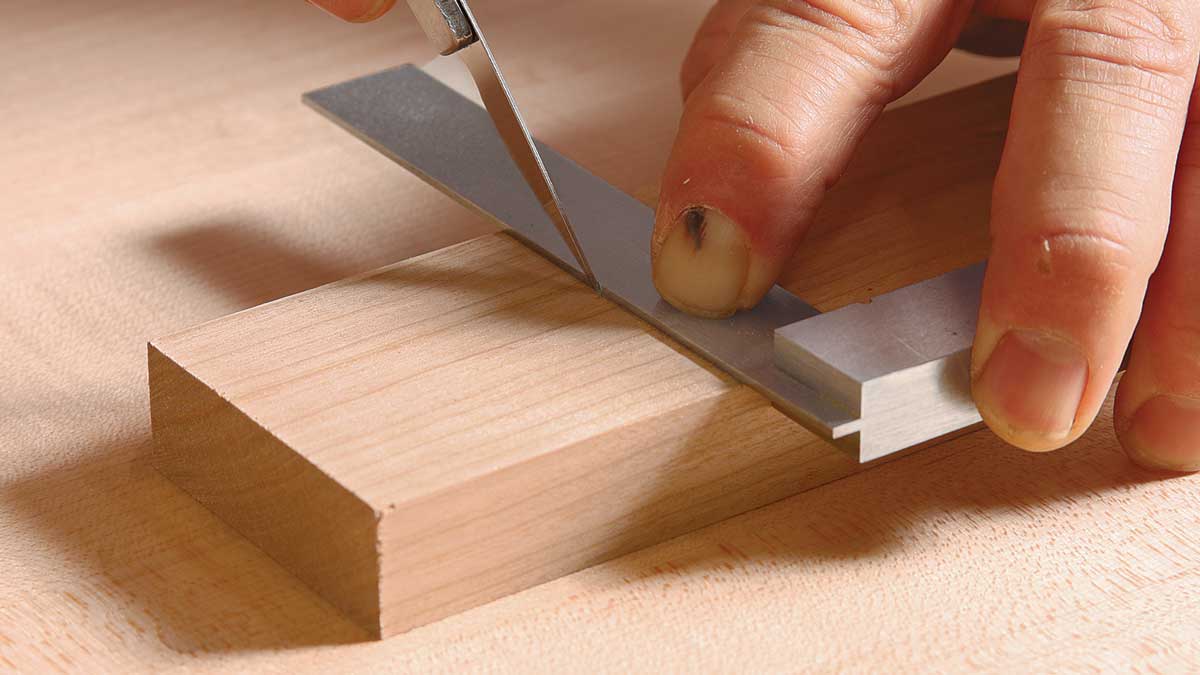

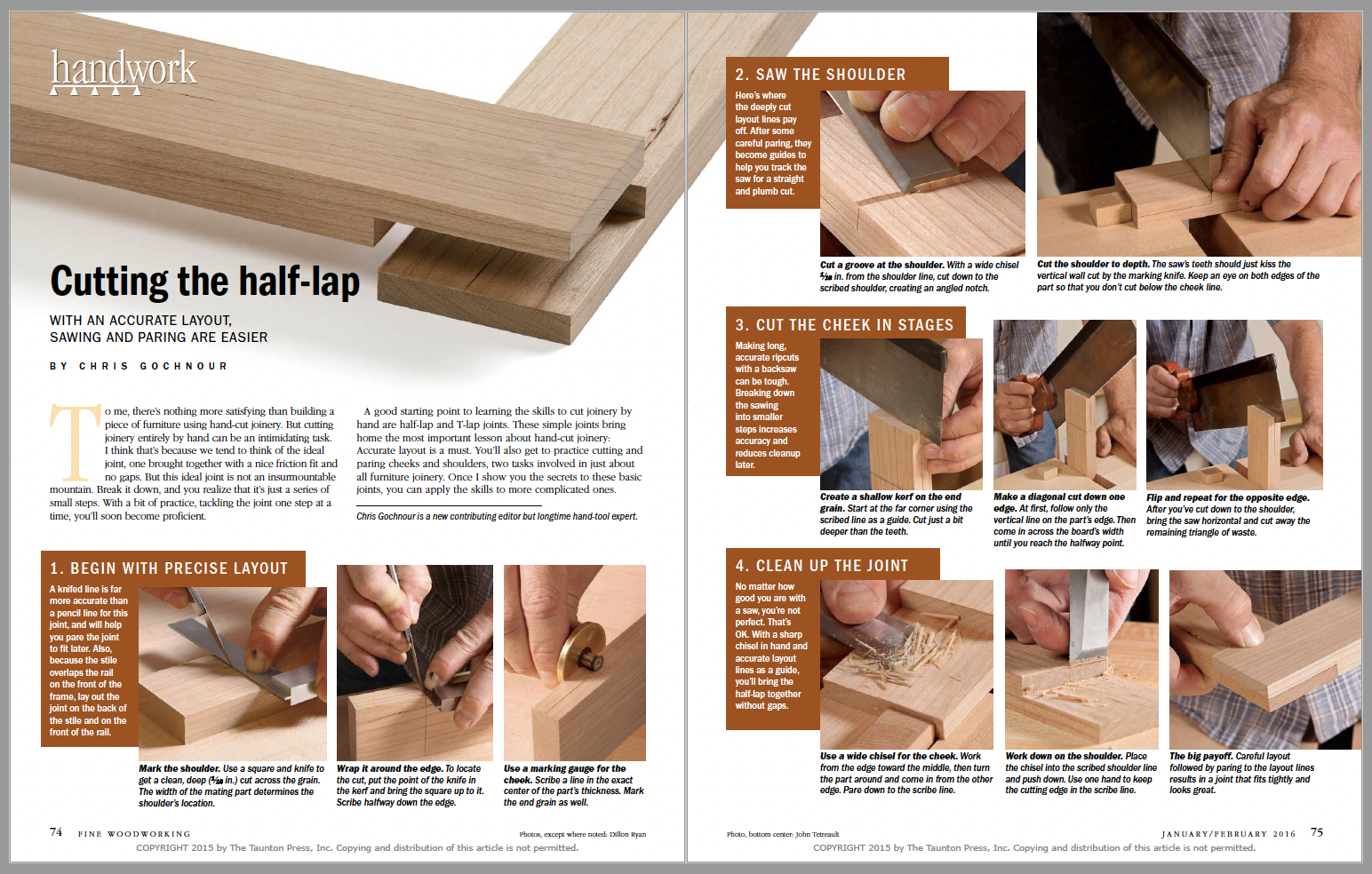

1. Begin with precise layout. A knifed line is far more accurate than a pencil line for this joint, and will help you pare the joint to fit later. Also, because the stile overlaps the rail on the front of the frame, lay out the joint on the back of the stile and on the front of the rail.

2. Saw the shoulder. Here’s where the deeply cut layout lines pay off. After some careful paring, they become guides to help you track the saw for a straight and plumb cut.

3. Cut the cheek in stages. Making long, accurate ripcuts with a backsaw can be tough. Breaking down the sawing into smaller steps increases accuracy and reduces cleanup later.

4. Clean up the joint. No matter how good you are with a saw, you’re not perfect. That’s OK. With a sharp chisel in hand and accurate layout lines as a guide, you’ll bring the half-lap together without gaps.

From Fine Woodworking #252

To view the entire article, please click the View PDF button below.

Fine Woodworking Recommended Products

Festool DF 500 Q-Set Domino Joiner

Veritas Standard Wheel Marking Gauge

Olfa Knife

Comments

I am in the process of building twenty four stall doors, each one using this joint. Much quicker and smoother to use a dado blade on both the radial arm and table saw and clean up chisel, shoulder plane, chisel plane, whatever is needed. Layout comes right off the pieces being used.

Log in or create an account to post a comment.

Sign up Log in