Essential Bandsaw Blades

With this basic blade kit, your bandsaw can tackle any task.

Synopsis: Choosing the right bandsaw blade need not be confusing. While the number of combinations possible with different tooth pitch, tooth profile, and blade size are endless, a set of three blades gives you enough versatility and performance to get any job done well. Roland Johnson says a 3⁄8-in.-wide, 6-tpi hook-tooth blade, a 1⁄4-in., 10-tpi regular tooth blade, and a 1⁄2-in., 3-tpi hook-tooth blade are all you need in the shop.

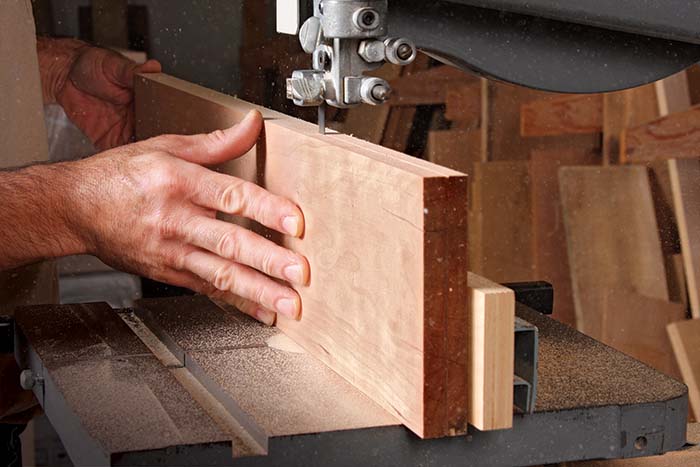

Bandsaws are the most versatile power tool in most woodworking shops. They can rip, resaw, cut circles and curves, and even crosscut without the risk of dangerous kickback. The key to getting the best results is picking the right blade for each job.

The choices can be confusing. You must understand how the blade width, the number of teeth per inch (tpi), and the tooth geometry all affect the cut you are trying to make. On top of that, you have to consider the wood’s thickness. To help you make the right choices, I’ve come up with a basic set of blades that can perform all of the typical furniture-shop cutting chores. Turns out, three blades are all you really need.

3 blades that do it all

While the number of combinations possible with different tooth pitches, tooth profile, and blade size are endless, a set of three blades gives you enough versatility and performance to get any job done well. A 3⁄8-in.-wide, 6-tpi hook-tooth blade, a 1⁄4-in., 10-tpi regular tooth blade, and a 1⁄2-in., 3-tpi hook-tooth blade are all you need in the shop.

Basic blade anatomy

Once you understand how the anatomy of a bandsaw blade affects the work, choosing the correct one for a specific task is easy. Consider the size of the blade and the number and size of the teeth.

Wide vs. narrow

The width of the blade plays a strong role in its performance.

A wide blade won’t deflect during heavy cuts, making it ideal for thick rips and resawing, but it can only navigate shallow curves.

A narrow blade can handle those tighter curves without binding, but it will tend to wander on large, gentle-radius curves and circles. It also doesn’t have the strength to cut thick material without deflecting or binding.

|

|

Coarse vs. fine

The number of teeth per inch (often called the pitch) affects the speed and smoothness of the cut. The basic rule is three teeth in the wood at all times, which prevents the blade from cutting too aggressively for the wood’s thickness.

A coarse-pitch blade has fewer teeth, but they’re large and cut extremely fast.

A fine-pitch blade has more teeth. Their small size makes for cleaner cuts but they tend to clog with pitch in thick material.

|

|

Tooth geometry

The shape of a bandsaw blade’s teeth are the most critical factor in how it will cut. Understanding these different shapes and when each is most effective will give you better performance from your saw and extend the blade life.

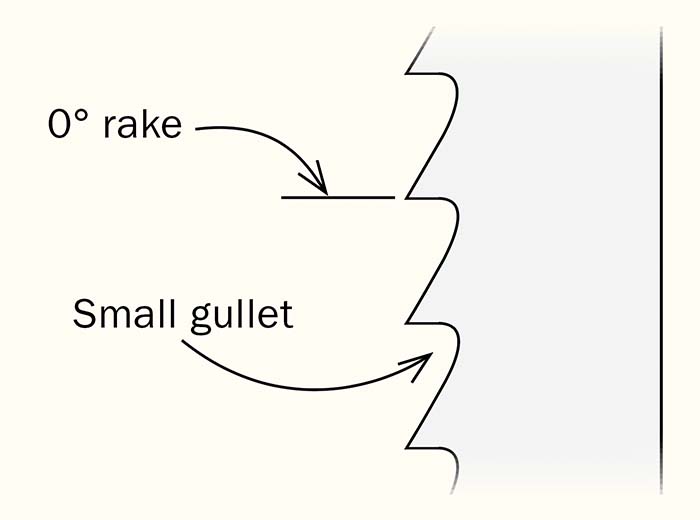

Regular Tooth

A regular-tooth blade has evenly spaced teeth with a 0° rake angle. This tooth shape provides clean cuts, but the small gullets clog quickly when moving a lot of dust, so they are not really suited for heavy ripping or resawing.

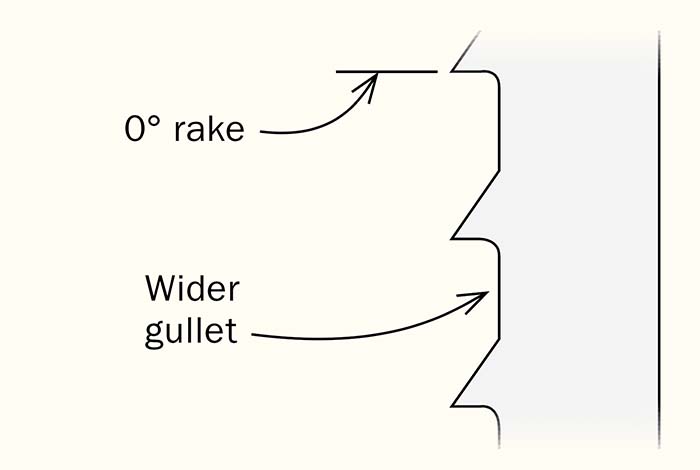

Skip tooth

A skip-tooth blade has a 0° rake angle, like a regular-tooth blade, but every other tooth is essentially skipped. The bigger gullets help clear away dust more effectively.

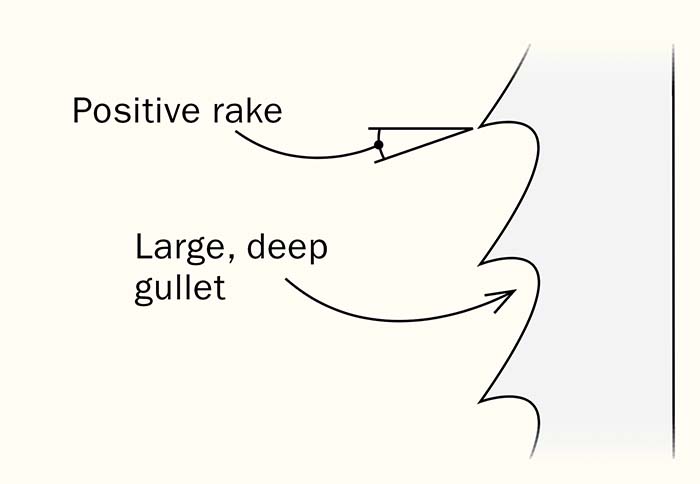

Hook Tooth

A hook-tooth blade has a positive rake angle and very large gullets. The teeth cut aggressively and the large gullets evacuate material quickly and effectively. The downside is that the cut surface is rough.

1. The all-around blade

While there isn’t a single bandsaw blade that does it all, having one that’s well suited for a variety of tasks will not only make your day-to-day tasks easier but will also speed up your work. If any blade could be considered all-purpose, a 3⁄8-in., 6-tpi, hook-tooth, high-carbon-steel blade would be it. This blade has enough width to handle most ripcuts in material up to 2 in. thick without deflecting but is narrow enough to cut mild curves. It’s also good for quick crosscuts. Following the rule of three teeth in the wood at all times, the 6-tpi blade is best suited for material 1⁄2 in. thick or thicker.

|

|

|

|

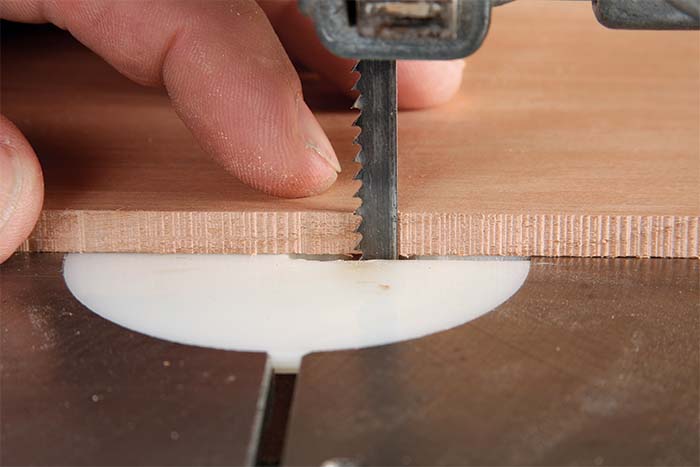

2. Blade for thin stock and tight curves

While the all-purpose blade is great to keep in the saw for general use, it’s too wide to cut truly tight curves and too coarse, or aggressive, for thin stock. My go-to blade for these jobs is a 1⁄4-in., 10-tpi regular-tooth blade.

With this blade, tight curves as small as 5⁄8-in. radius are a piece of cake. And the fine teeth provide a clean-cut, especially in thinner material—you’ll be able to cut 1⁄4-in.-thick stock without it splintering or tearing out. Sawing curves, especially circles, is more about crosscutting than ripping, which results in fine, short-grained sawdust. Despite the small size of the gullets, they adequately clear that dust.

|

|

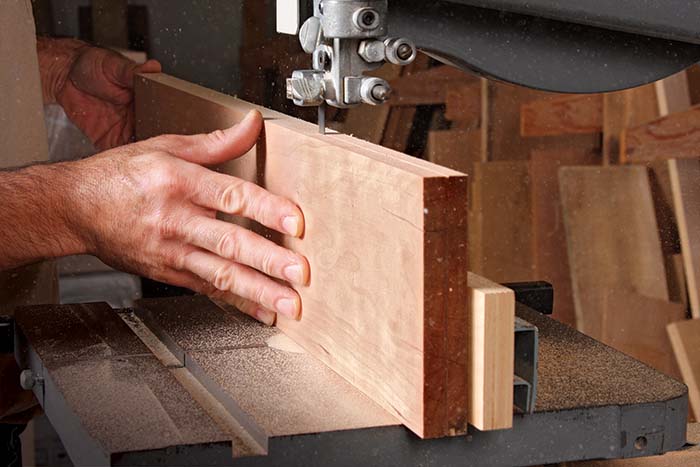

3. Blade for thick stock and resawing

Another task at which bandsaws excel is resawing and ripping thick stock. The thin blade has a smaller kerf than a tablesaw and there’s no danger of kickback. Ripping wood creates lots of stringy sawdust that easily packs the small gullets of an all-purpose blade, robbing the saw of power and keeping the teeth from easily cutting into fresh wood. The best choice for ripping is a 1⁄2-in., 3-tpi hook-tooth blade. The aggressive teeth and big gullets of this blade cut fast and evacuate a lot of dust quickly. Because of the low teeth per inch, 1-in. stock is the thinnest stock you should cut with this blade. For heavy cuts, a blade must have sufficient beam strength to resist deflection when force is applied to its cutting edge. The 1⁄2-in.-wide blade works well for cutting stock from 1 in. to 6 in. thick (or wide for resawing).

For those who do a lot of resawing of stock or veneers, a dedicated resaw blade can be a great addition to this set. A 5⁄8-in., 3‑ to 4-tpi variable-pitch blade is perfect for clean, accurate cuts in thick or wide material (up to 12 in.). A variable-pitch blade’s fluctuating tpi count helps eliminate the vibration that is often produced when working with thick stock.

For blade material, I prefer high-carbon-steel blades for ripping domestic wood, bi-metal for abrasive wood, and carbide for really nasty stuff like jatoba. For resawing, I prefer a true carbide-tipped blade like the Laguna Resaw King ($150). If that’s out of your price range, the carbide-impregnated SuperCut Wood Saver Plus ($70) is also a great option.

|

|

Make your blades last

Make your blades last

You’ll get poor results with a blade that’s dirty or dull. When the gullets get lined with pitch, the blade has an increasingly hard time evacuating dust. As a result, you need to use excessive force when feeding the wood, causing the blade to wander or the thrust bearings to lose their setting. I scrub dirty blades with a brass brush (left; make sure to turn the wheel counterclockwise by hand as you clean), and I also thoroughly clean roughsawn boards before cutting them (below). A dull blade will also cause problems. If you need to push harder to make cuts, if the blade starts to drift consistently in one direction or wander, or if you notice increased burning or smoking, your blade is dull.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Sawstop Miter Gauge

Compass

Comments

No mention of carbide tip bandsaw blades. Not cheap but worth every penny. It is smooth cutting, stays sharp, doesn’t wander and my 3/8 still does quite small radius cuts.

I echo the carbide tip blades comment. More expensive but wear like iron. Do not drift. Very clean cut surface. I use one on each of my 14 and 23 inch saws. 3/8 on the 14 inch saw and 1 inch on the 23. Recommend them highly.

Log in or create an account to post a comment.

Sign up Log in