Track Saws

For fast, accurate cuts in plywood and more, these compact saws are hard to beat.

Synopsis: Track saws have come a long way since they were developed about a decade ago with basically one mission in mind: cutting up sheets of plywood. They are now used for all sorts of jobs. We tested seven of the saws currently on the market for power and quality of cut, blade deflection, and ease of handling. In the end, three saws stood out. Models tested include DeWalt DWS520SK, Festool TS 75 EQ, Festool TS 55 REQ, Grizzly T25552 Master Pack, Mafell MT55CC, Makita SP6000J1, and Triton TTS1400.

I was one of the first people to review the Festool 55 track saw when it came on the market almost 10 years ago, and I went around for several years afterward telling all my woodworking friends to buy the tool.

The magic of the track saw is in the track, which has a nonslip surface underneath and a zero-clearance strip along the edge. In seconds, you can line up that edge with your layout marks, drop the saw onto the track, and make a perfect cut, right on the line. Add the ability to plunge in and out of a cut and you have a truly unique tool, unmatched at a number of tricky tasks that range far beyond its original mission: cutting up sheets of plywood for cabinet work.

Since my first review, other manufacturers followed Festool into the market, and Fine Woodworking thought it was high time for a lowdown on the whole lot. We reached out to all of the manufacturers and netted seven saws for our test. Shop Fox and Scheppach declined to participate.

Saw and track combinations vary a bit, so in each case we ordered the saw with a track at least 48 in. long, because a track saw should be able to crosscut a sheet of plywood. And for some insurance on critical cuts, we also ordered the accessory clamps that lock the track to the workpiece.

To evaluate the power and quality of cut, I used the saws to cut through a wide variety of thick hardwoods—ripping 8/4 maple and oak and 4/4 alder, and crosscutting a 1-1⁄2-in.-thick maple butcher block. I also took a skim cut on the edge of the butcher block to check for blade deflection, and I cut a variety of veneered sheet goods.

All of the saws produce clean edges under their zero-clearance strips, and the best deliver a clean edge on the outboard side of the kerf, too. I also noted the smoothness of the plunge action and how comfortable the handle was.

Some of the saws set the depth in metric units and others in imperial, but I didn’t find the measurement units to be a big issue. However, I do like the fact that some saws factor the track height into the depth measurement.

I find track saws to be very useful when cutting bevels. To test their accuracy, I used the saws to cut two long 45° bevels in plywood to see if the joint would close with no gaps. In the process I evaluated the bevel gauge for accuracy and readability. Some of the saws have a catch that prevents the saw from tipping off the track when bevel cutting, a handy feature.

From Fine Woodworking #255

To view the entire article, please click the View PDF button below.

|

How to Break Down Plywood With a Track Saw |

|

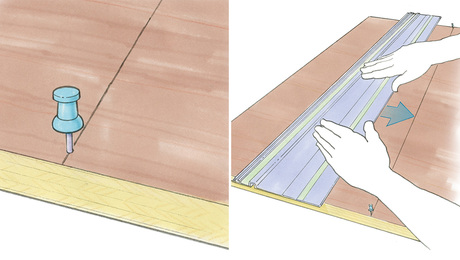

Workshop tip: Use push pins to align your track saw |

|

How To Make a Tracksaw Crosscut Table |

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Makita SP6000J1 Track Saw

Stanley Powerlock 16-ft. tape measure

Comments

I am a big fan of my plunge saw, especially as it is actually quite simple to make your own track (A router and a straight edge are the only tools I use). Leave it wider on one side to give space for clamps.

This opens up many more possible uses for the saw.

A short length of track, hinged to a backer board for example, can imitate a chopsaw. Use a pin as well, and you can make compound miter cuts.

These tools are very useful if you have a small workshop and or a low budget.

Log in or create an account to post a comment.

Sign up Log in