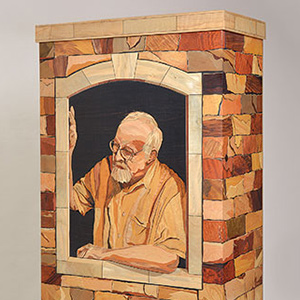

Synopsis: David Lamb produces marquetry patterned after a winter frost. See how he chooses the wood, cuts it into billets, and then slices it into veneer. Then he uses a pattern to form his intricate designs.

David Lamb’s frost-patterned marquetry begins with birch crotch sections 3 or 4 ft. long. When he’s collected a few, he takes them to a friend with a bandsaw mill. One cut through the crotch reveals whether the figure within is strong enough to warrant the effort of cutting it into billets. Lamb air-dries the billets for some months on a hot, high shelf in his shop, then cuts them into veneers. He likes to get the veneers down to about 6% moisture content, using a moisture meter to check and a microwave oven to finish the job, if necessary. Then he sends them through a thickness sander. Lamb likes birch for its warm tone and for the connection to so much American period furniture in which birch was used as a substitute for satinwood. He also doesn’t mind that birch is so commercially neglected that he often gets the material for free.

David Lamb’s frost-patterned marquetry begins with birch crotch sections 3 or 4 ft. long. When he’s collected a few, he takes them to a friend with a bandsaw mill. One cut through the crotch reveals whether the figure within is strong enough to warrant the effort of cutting it into billets. Lamb air-dries the billets for some months on a hot, high shelf in his shop, then cuts them into veneers. He likes to get the veneers down to about 6% moisture content, using a moisture meter to check and a microwave oven to finish the job, if necessary. Then he sends them through a thickness sander. Lamb likes birch for its warm tone and for the connection to so much American period furniture in which birch was used as a substitute for satinwood. He also doesn’t mind that birch is so commercially neglected that he often gets the material for free.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Whiteside 9500 Solid Brass Router Inlay Router Bit Set

Bahco 6-Inch Card Scraper

Comments

Beautiful! Page 2 of this Pdf is not displaying. Thx for your help.

The full article isn't showing up in the pdf.

I went to that issue in hard copy. The second page is the back cover that displays the work. The actual text is only one page (p. 86).

Hello, the PDF of tis article is still incomplete as other comments suggest.

Log in or create an account to post a comment.

Sign up Log in