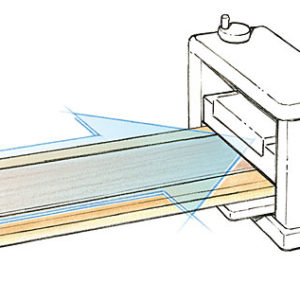

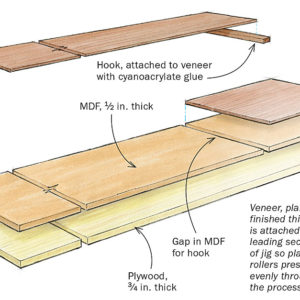

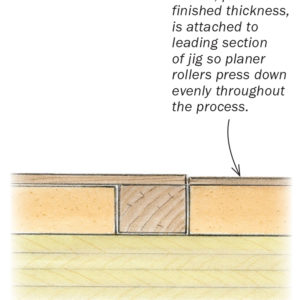

Bandsawing your own veneers allows you to spread a beautiful board over an entire piece of furniture. You joint one face of the board before each bandsaw cut, but the saw still leaves a rough face on the other side of the veneer, which is tricky to smooth on such a thin piece. A drum sander or wide-belt sander would do the job, but those are pricey machines. This jig lets me run bandsawn veneers through my thickness planer. It also holds veneers for handplaning. It’s a simple sled made from MDF and plywood. You’ll also need an extra sheet of veneer planed to finished thickness. I start by resawing the veneers to 3⁄32 in. thick. Then I glue a square strip of solid wood (I call it a hook) to the leading edge of each piece (jointed face). The hook fits into a gap in my jig (see drawing, right). If the veneer is not sitting perfectly flat, I use small pieces of super-thin, two-sided transfer tape to hold down the corners. I set the planer for a 1⁄32-in. cut, which will leave the veneer 1⁄16 in. thick. To help dampen vibration, I pull the workpiece back and press it down on the jig as it is being fed into the planer. After the veneer has been planed, the “hook” simply snaps off and is often reusable.

—JEFFREY KUSAMA-HINTE, New York, N.Y.

Fine Woodworking Recommended Products

AnchorSeal Log and Lumber End-Grain Sealer

Incra Miter 1000HD

Grout float

Comments

I've done this and it works great as long as you don't fire up your high powered cyclone dust collector. Ask me how I know.... ;)

2 comments:

1. In order to make this jig you need a piece of veneer planed to the required finished thickness? If I could do that already seems like I wouldn't need the jig.

2. First commented recommends not using the dust collector to plane the veneer. For me this is a difficult problem since I use an Oneida cyclone on my planet. If this really a problem the jig is much less useful for me; maybe not at all.

@grbmds You don't need the piece of planed veneer to make the jig - you can plane it on the first pass through the jig. Really it could be any material that matches the final thickness of the veneer, it's only purpose is to provide consistent traction on the planer's feed rollers. Not sure what that says for the trailing end of the veneer. Would it help to have a "follower" of some sort.

Log in or create an account to post a comment.

Sign up Log in