9-in Dewalt Radial Arm Saw

At $125 it was too good of an opportunity to pass up.

One drawback of being a tool junky is that I’m always dragging some old forgotten chuck of iron back to my shop. A few months ago a friend mentioned that his dad was disposing of his woodworking tools and wondered if I knew anything about radial arm saws and what they might be worth. His dad wanted $125 for one and thought maybe that was too much. A few questions determined that it was an early Fifties DeWalt 9-inch in little-used condition. I couldn’t pass up the chance to buy an early DeWalt, which in my estimation is the best of the breed, so now I have another chunk of ol’arn to add to my collection.

The saw was purchased new by my friend’s dad and was carefully used and well taken care of. The only weird modification was plywood glued to the original maple table, maybe a way of preserving the top? Thankfully it hadn’t been clamped tight when glued up and I could simply pry the junk off and clean up the glue. The original maple table is in very nice shape. The rest of the saw is virtually new and I really enjoyed sifting through all the original literature that came with the saw, pure Fifties stuff with lots of pegboard used in the projects! DeWalt even included plans for a “Modern Workbench” using the radial arm saw as it’s centerpiece. Yikes.

There’s a lot of controversy about the attributes of a radial arm saw and I’m a proponent of them. I’ve had a 10-inch version of this same vintage (and Futurama-green color) for nearly thirty years and wouldn’t be without it in my shop. There’s simply no better tool for accurately and cleanly crosscutting lumber. There, it’s in print, let the responses begin!

This little gem can crosscut 15 inches of 1-inch stock. If you are a tablesaw sled user who considers 15-inch crosscuts easy to achieve, try crosscutting the end of an 8-foot 10/4 oak plank, accurately, with your sled. It’s far easier to saw wide, thick or long stock when the stock doesn’t have to be moved across the blade. My 10-inch saw will also crosscut 3-inch thick hardwood with relative ease which can be a major challenge with most chop saws.

Radial arm saws have a reputation as being dangerous, overly-aggressive-cutting saws, but the real culprit isn’t the saw, it’s the blade. Radial arm saws require a negative hook angle blade, just like a chop saw. Standard positive hook angle blades simply cut too aggressively for a pull saw, and this saw was equipped with a 24-tooth standard blade – very aggressive – so a proper blade is the first step in getting it back to work. A little setup (squaring everything) and some needed maintenance (lubrication) and I’ll put the little beauty to work.

One important tip when considering putting a radial arm saw in your shop: buy an early saw, one built before the late Sixties or early Seventies. The early saws are built like brick outhouses with lots of cast-iron and hold their settings even when heavily used. The old DeWalts were so well built and so easy to setup it’s easy to see why the Original Saw company makes dead-ringer copies. So the next time you’re trapped in Craigslist check out listings for radial arm saws, you might find a worthy addition to your shop.

Fine Woodworking Recommended Products

Stanley Powerlock 16-ft. tape measure

Shop Fox W1826

Comments

Roland - Thanks for confirming everything I already love about my old DeWalt mid-50s RAS. Bought it at an auction for $70, cleaned it up and replaced the bearings and it runs beautifully. I have it set up for perfectly square cuts and never move it from there. Thanks for the info on blades. Looking forward to more Talking Tools!

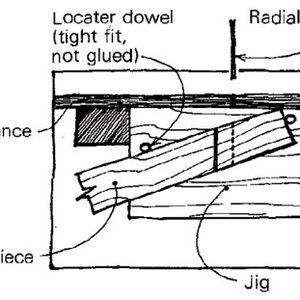

Rowland, I think you will love the saw. My funky green 9 inch is my primary circular saw in my very small shop for cross cutting, mitering and ripping mostly sheet material. (I gave away my Delta contractor's saw after a few months). Tips: 1. It is very accurate if kept clean and the adjustments checked periodically; 2. The Mr. Sawdust self published manual is well worth it if it is still available. His replacement table design is terrific even though my maple top was in decent shape; 3. With a bunch of spare fences, working cuts to a knife line is easy and very accurate; 4. Fences are consumable; 5. A plug in paddle type on off switch attached to the front of whatever stand you use is much more convenient than the fragile toggle switch on the arm; 6. Clearance to each side is really necessary to have safe control when ripping. Downsides: a bit loud, low power, and tear out on top of a work piece is hard to avoid (knife lines help).

Matt

I have the same exact saw. My father-in-law gave it me many years ago, and it was the saw that got me into woodworking. The saw is unbelievable on how well made it is, and how long it holds its tolerances. The arm has some sag in it, but I compensated. As you mentioned, nothing better for crosscutting stock, but also great in cutting dado's. Anytime I need dado's, that saw is the go to machine. I put a new table on, based on the instructions from the Mr. Sawdust book. Wally Kunkel knew everything about those saws, and his book is a must have for anyone who has one of these priceless saws.

I bought my Green best-friend originally in the fifty's. It is a gem as a crosscut saw but beware the rip cut.I almost 'speared' my firstborn when he walked by as the saw launched a thin, narrow piece when the blade rode up on the work surface. Never again.

Roland,

Thanks for the review, and overview of the Dewalt RAS. My very first saw was a Dewalt 7770 10" RAS, bought new in 1980. It, too, was an amazing tool, with all the attachments, to get me into woodworking after my school shop years from 7th to 12th grade, and MANY years in between.

I have used the RAS as my go to tol for cross-cutting for many years, and a venerable tool in my wood shop since my pursuit of fine woodworking around 2007.

As good a tool as the RAS is for cross cutting, I found I needed a wider cross-cut for panels and other pieces I was building. I came to the conclusion that the RAS had to go, and I would replace it with a Festool MFT table and a Makita track saw. I sold the RAS for $300,

sold a collection of solid mesquite lumber for $400,( I found I was allergic) and spent $850 for the MFT+Makita.

I now have a crosscut of 24"+, a much finer cut, and am very pleased with the utility and safety of the new saw.

I have the same one and it's for sale! No one wants it for $50. So it Ben on the loading dock with a sign saying free. No takers.

I started my career in woodworking 27 years ago with a radial arm saw. I got it because I remembered an old childhood friend's father who had a DeWalt, and he had been the first person I had ever known who had actually worked with hardwoods. I used it for about five years to build furniture of varying quality, and kept it after I bought my first table saw, a Delta contractor's saw.

Time and experience taught me that the saw, even when well-tuned (and I did learn how to tune it) was unsafe. It was unpredictable, and the exposed blade was asking for loss of a finger or worse. Most people have figured this out, and in light of the awesome technology present in sliding miter saws, as well as table saws with flesh detection, radial arm saws are sliding into the past like square head jointers.

I'm not going to shake my finger at you, Lon. But some anachronistic technology needs to fade. When you can buy the tremendous tech available now -- even the circular saws with tracks are something else -- there's no money saved that will replace a finger or hand lost -- or a kickback and perforated intestine to the gut. If you think safe tools are too expensive -- the only real reason to buy one of these clunkers -- I can assure you, ignorance and the following hospital visit are far more expensive.

As a lover of vintage anything -- whether it's cars, motorcycles, instruments, or tools -- I know that my use of older things isn't at all tied to the fact that newer, safer/easier items are too expensive or out of my reach. There's intrinsic value in holding onto a finely crafted, vintage piece of engineering and using it. If this were a 1965 Ford Mustang, which had no airbags, no ABS, and no power steering (current "standard" safety equipment), I don't think anyone would say you should get rid of that "clunker" and get a much safer, more efficient 2016 Hyundai Sonata. I completely agree that the tools of yesterday are much more dangerous, but that isn't a singular determiner of their value.

Well said Dillon.

It's nice to see the comments about my post, I was hoping to start a discussion about this often maligned saw.

I use my RAS strictly for crosscutting, it's not a rip saw; too awkward, too dangerous. I'm not a believer in the RAS being a one-tool workshop.

I will say, however, that an RAS is no different in operation, and the considerations involved with that operation (correct blade, careful operation), than any sliding miter saw. It's the same physics except a good RAS is much more robust than most sliding miter saws.

To make a radial arm saw work well you need the correct blade, a freely moving motor/arbor assembly and the sense to support work adequately and keep your hands out of the blade's path, pretty much like any power saw ever made. If the arbor/ motor assembly requires any effort to pull into the cut it creates a perfect storm for catching and jamming the blade. Imagine a chop saw with the swing arm bound up requiring force to push it down into the wood, pretty dangerous.

I use my sliding miter saw for making angled cuts, it's easier to change cutting angles than my RAS, but I seldom crosscut thick stock with it, the relatively lightweight arbor/motor is harder to control.

Periodcraftsmen - where are you located? I would be interested.

Roland,

My first stationary power tool was a Delta RAS circa 1965; with it I framed and finished a 3800 sqft house. I used it for ripping and cross cutting with ease. This was long before negative rake blades were common knowledge. The only mishap happened when my dad launched the tongue off a piece of WP4 paneling through a thermopane sliding door. I still have the saw, but there is insufficient room in my shop so it resides in a storage room. I was anticipating building another home and envisioned the saw at a central position in the living room while the structure and finish blossoms around. Alas, we bought fully complete 2nd home and the RAS awaits a new purpose. Perhaps, I keep it just for the nostalgia and memories. Oh what should I do? --DKH

Roland - Thanks for this blog post. It brought back fond memories of woodworking with my dad. I still remember the day in the late 1950's when we brought home my dad's new Dewalt RAS. Even at 9 years old, I could tell how happy and proud my dad was. He worked making molds in a foundry, and had actually worked on many of the castings for the saw. That day I think we tried all of the compound angle cuts in the instruction book. This was the only stationary power tool in my dad's basement, and the tool I started with when I began woodworking. My dad and I made a lot of sawdust with the Dewalt, and I still use it when I'm doing projects at my parent's house. When I bought my house in 1977, a 10" Craftsman RAS was the first stationary tool I bought, and it's still in use today. I've always been a strong proponent of the RAS, and it wasn't until 1992 that I bought my Unisaw. Thanks for the memories!

I still have the one my dad bought used almost 60 years ago. I don't use it for anything that can't be done with a compound sliding miter saw, but it works great and I have the space for it. Why change?

Roland I bought my Dewalt RAS model 1251 back in 1985 and still use it now. It's an Italian built unit. Until about 3 years ago when I purchased a table saw I used my RAS for everything wood and aluminium, cross cut, rip cuts, dados, etc. I never ever felt threatened by its use and after reading the book by Mr Sawdust the accuracy has been excellent. Now with a table saw I use it less but still use it just not as daily as I used to.

The 1251 is nice unit but just not built like the early units like yours.....it's less robust and solid and so needs more frequent adjustment to keep it tuned. Once tuned it's as accurate as my table saw. The table saw is more consistent and does not need as much attention to keep it dialled in and so what I use more frequently now, especially for rip cuts.

I won't be getting rid of my RAS ever!!

Roland,

Thanks for this article. I have my uncle's Dewalt MBF from the mid fifties. It looks just like yours. It's one of my favorite tools for a number of reasons. First I remember as a little guy sneaking off to my Uncle Clyde's garage shop behind his home to admire the tools. The tools seemed most wonderful to me and this Dewalt was the centerpiece of his shop. I also like that it spent time in my late brothers shop and more recently my (then) young sons and I built our first boat dock with it. I've had several RAS(s) and am aware of their limits, but I still like using them and this one in particular. I collect old machines and perhaps more importantly, to me, I collect the stories that come with them.

OMG...memory lane. I believe my first RAS experience was in woodworking shop in a small Iowa High School in the early 50's. For sure I remember the large RAS at the lumber yard about 1952. I was the "yard boy" and was allowed to crosscut dimensional lumber for customers. I got my own Dewalt RAS in the mid 60's and moved to new cities twice with it. I made mistakes with it and yes, it could throw pieces of wood. Later I had table, crosscut and band saws, and believed I no longer had room for it in my shop crowded with a small shaper, a thickness planer and a small edger. I did not want to give it to just anyone but finally found an experienced wood worker who understood how to use a RAS and safety measures. I think it is dangerous to try to rip on a RAS.

So I tried to figure out how do dispose of it...I was not going to give it to just anyone! found an experienced carpenter/woodworker

user-3421365October 23rd, Being as how I am considered to have average intelligence, please explain to me how your sliding miter saw is NOT a radial arm saw. The 4 features missing from YOUR radial arm saw are lack of the depth control, lack of ability to cut dadoes, lack of ability use as a shaper, and on some brands, install a chuck and use like a pin router. I have been separated from my Craftsman 10" RAS for 10 years because of lack of space. I have had 2 of those sliding arm radial saws- both well know brands; both equally junk. And yes, unless you really knew what you were doing, ripping with a RAS could be scary. But the use of hold downs and an intelligent feed rate, the radial arm saw was a pretty good ripper. My old Craftsman carriage rode on 2 steel rods and 4 ball bearing guides. how is this different than DeWalt, Ridgid or any of the other sliding arm radial saws. I learned woodworking in my grandfathers cabinet shop. Powered by a donkey engine, leather belts, shafts and pulleys and mostly homemade machines. There wasn't a machine there that wasn't safe- until a human started it. Take the human factor out of things and danger is reduced tremendously. I guess a swing arm saw would drive you nuts just looking at it. Because I don't work with large panels or stock over 8" wide, I can get by with a 12" CHOP saw- nothing more than a motorized version of the swing saw. Get off your high horse and ride with us pony riders.

Roland,

Thanks for the comments re RASs. A Sears 10" unit was my first stationary power tool back in the 70s. It continues in my shop although I also have a collection of Sawstop, Festool, and Laguna machines. It handles the majority of the rough(and sometimes finer) cross cutting jobs. It's basic functionality is great. It is a compromise or a flirtation with danger to use it for much else. I do enjoy looking through the book that came with it. Pegboard was alive and well in the 70s also.

It does take me back. My father was a successful (measured in popularity rather than money) artist. As I look back, his knowledge of woodworking was better than average because he had to build a lot of his own stuff...aisles, workbenches, framing for his paintings...and once I came of age, I took over his framing. He had a wonderful DeWalt radial arm saw which I became very proficient at using when I was 16. Many of his paintings out there are framed by a teenager with a DeWalt. He even had a miter vise for holding corners in place as I glued and nailed them; but I was often impatient and would not clamp them long enough for the glue to dry. Gesso, white paint and gold leaf crayons would cover a lot of ills.

My father had a Model GP, 12" blade, long arm, which I now have. It will crosscut to 20", no problem. I have also used it to rip planks for various projects and never had any safety concerns. I also have 2 9" DeWalt RASs, one MBF (~3/4 hp) and one MBC (~1/2 hp). I find that they are no more dangerous than many power tools as long as you understand them and treat them as you should any power tool.

Can anyone recommend a suitable blade?

Inspired by this article, I managed to find and old Dewalt 925 online, in practically new condition. It does need a new blade on it though.

Log in or create an account to post a comment.

Sign up Log in