Creating compound curves

Designer Will Acland and maker Tim Smith built the bent-laminated frame of their curved chair using straight-grained, flitch-cut European ash veneer and MDF forms

Synopsis: Designer Will Acland and maker Tim Smith built the bent-laminated frame of their curved chair using straight-grained, flitch-cut European ash veneer and MDF forms. The parts were shaped using an angle grinder, rasps, files, and spokeshaves.

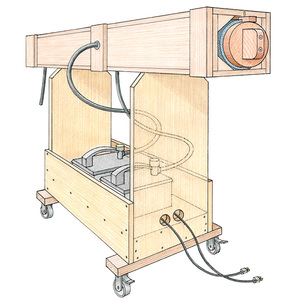

Designer Will Acland and maker Tim Smith realized that because their bent-laminated chair (see the back cover) was so full of subtle and complex curves, there would be no easy way to build a prototype to assess the design for looks and comfort. So they decided to create the seat and back first, bending fiberglass over MDF forms to make the compound-curved substrates for the leather upholstery. Next they made an MDF structure to cradle the seat and back so they could be tested for comfort (see p. 90). Then they moved on to building the chair’s bent-laminated frame. Acland designed the frame joints to meet in curves, echoing the other rounded forms in the chair.

A chair frame in the raw; Straight-grained, flitch-cut European ash veneer, 0.6 mm thick, was used for the frame. After ripping the sheets into strips and cutting them to length, Smith sorted and numbered them to keep them in the order they came from the tree. Major bending; Smith built MDF forms to bend the chair parts. Applying epoxy to all 80 strips in the front leg-and-arms component and clamping it up took three hours. Out of the bag; Once the epoxy cured, Smith used hash lines to indicate where wood should be removed during the initial shaping.

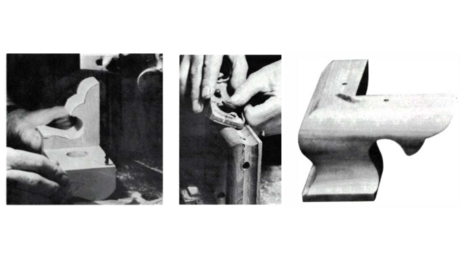

Square before circle;

Smith cut the components to a square section before shaping them round. He made some cuts with a saber saw, others with an Arbortek angle grinder with a planer head. Freehand shaping; Smith used an angle grinder for some of the shaping and rasps, files, and spokeshaves for the rest. A tent of plastic sheeting contained the dust. Joinery cradle. Smith cut the joinery while the frame parts were still mostly square. The short veneers he added at the intersections let him shape the branch-like swells at the joints.

For the full article, download the PDF below:

Fine Woodworking Recommended Products

Ridgid EB4424 Oscillating Spindle/Belt Sander

Log in or create an account to post a comment.

Sign up Log in