A Rippin’ Good Time

We have blades that cut more efficiently and leave a better cut surface than ever. And this has led to the debate about the need for any blade beyond a good combination blade.

Tablesaw blade technology and CNC machining are bringing us blades we couldn’t have dreamed of a couple decades ago. Improved and ubiquitous, carbide teeth are not only better at shearing wood fibers but they also stay sharp longer and, with the increased accuracy of machining, allow tighter tolerances for consistent side relief angles and cutting angles. What does this all mean to the average woodworker? Well, we have blades that cut more efficiently and leave a better cut surface than ever. And this has led to the debate about the need for any blade beyond a good combination blade.

I’m a huge proponent of appropriate blades for specific needs. I will use my combination blade for general cutting on the tablesaw when I’m ripping thin (3/4 in. or thinner) stock or rough crosscutting stock, but when it’s time to rip heavy stock or to make precise, clean crosscuts, I change blades.

Ripping wood involves very different needs than crosscutting. When we rip wood, we cut parallel to the wood’s grain structure (lots of long, fibrous tubes), producing stringy sawdust that is easily compacted into blade-dragging and gullet-filling detritus. Large gullets between the teeth and larger side clearance angles on the teeth of a dedicated rip blade assure these strands of sheared wood can be evacuated quickly from the sawkerf and don’t end up packed in the blade. The drawback to a dedicated rip blade is a slightly rougher cut, but I’m going to be jointing the rips so it’s not a big deal.

evacuated quickly from the sawkerf and don’t end up packed in the blade. The drawback to a dedicated rip blade is a slightly rougher cut, but I’m going to be jointing the rips so it’s not a big deal.

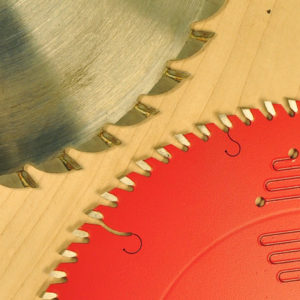

You can see that the gullets on the 20-tooth rip blade on the bottom are significantly larger than the 40-tooth blade at top. And you can also see that there is a different geometry to the sharpening on the dedicated rip blade. This rip blade can hog its way through thick hardwood without breaking a sweat, yet it still leaves an acceptable surface. It will make your lower-horsepower saw a much better ripping machine.

On the other hand, if we compare the 40-tooth combo blade to an 80-tooth crosscut blade, we see a huge difference in the gullets: the crosscut blade has tiny cavities for sawdust removal.

Crosscutting shears across those pesky wood fibers and creates short, fragmented sawdust that is easy for a blade to evacuate. No packing the gullets here (unless you’re working with very resinous woods, then you’re sunk). The benefit of a dedicated crosscut blade is the silky-smooth surface it leaves on end grain and the minimal tearout on the side where the teeth exit the wood. The large number of teeth also makes trimming wood where the blade is not contained in a kerf easy, as there are always teeth involved in the cut, helping to eliminate blade distortion and vibration.

So my routine is to use a dedicated rip blade (20 to 24 teeth) for thick stock, a combo blade for general light-duty cutting, and a dedicated crosscut blade (60-plus teeth) for precision crosscuts.

Taking a few minutes to install the correct blade can save time, material, and frustration.

Do you change blades or just compromise?

If you have any questions that you’d like answered by Rollie, send them to [email protected].

Fine Woodworking Recommended Products

Veritas Standard Wheel Marking Gauge

Estwing Dead-Blow Mallet

Rockler Deluxe Panel Clamp

Comments

In my Table saw I have a rib blade in there unless I'm doing miters the I use a dedicated crosscut. I tried the combination but it seems to be piss poor at either ripping or crosscutting. I have a Radial-arm I use for most crosscutting . Yeah I know a Radial-arm saw, but it is so handy, its paid for and I enjoy the extra table it provides. Mike and Matt talked about having a combination in their saw so I tried it again but it just does not as good for ripping.

Rollie, I change blades for ripping thick hardwood. Otherwise I leave my thin kerf Freud Premier Fusion blade on the saw.

My solution to changing blades was to buy a second saw. One with 80 tooth Freud crosscut and the second with 24 tooth Freud rip.

When I expect the best results and want the cleanest cuts I change to separate, dedicated blades designed by the blade manufacturers to optimize the cut. After all, that cutting edge is where the "rubber meets the road" in order to get the best results from a tool that can cost upwards of $3,000 and that has few other user-controllable adjustments. I also always use dust collection and I remove and clean my blades at least once per week. Obsessive? Maybe so, but I fully expect superior cuts right off my saw and I don't believe in "muscling" through cuts and burning wood. If you understand the difference between rip and crosscut blades, have spent the money to own both, and then you don't change the blade for the type of cut you're making, I call that "lazy."

I almost exclusively use rip blades (Freud) in my table saws because they cut flat-bottomed kerfs. This is very useful for joinery work. I don't use that much plywood, but if I did I would, indeed, use a blade dedicated for such use.

For almost all the rest, the band saw works really well.

I used to obsess over the cut that comes off the table saw, but since I use hand tools for all final surfaces, the cut quality is not as important. No matter how great the cut is off the table saw, no table saw cut can match the clarity of a hand planned surface.

As MacGregor said, no table saw cut can match the clarity of a hand planned surface. Our hand are the most precise tool we have, for now.

Log in or create an account to post a comment.

Sign up Log in