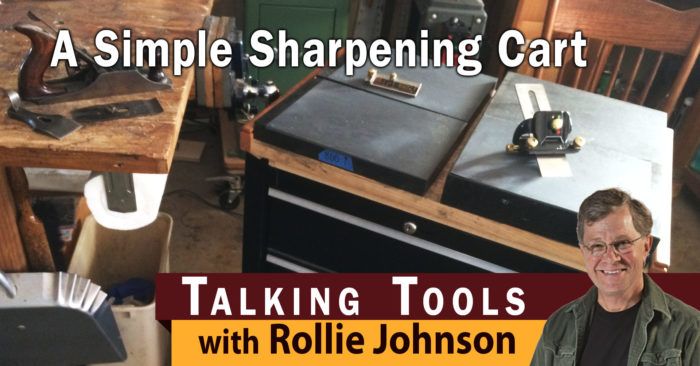

A Simple Sharpening Cart

For Rollie Johnson, the best way for him to keep his tools sharp is to make sure it's easy to do, so he put together a workstation that he can wheel anywhere in the shop

I’m probably going to rile a few folks with this blog simply because talking about sharpening often borders on talking about religion or politics; everyone has an opinion and firmly believes the discipline they have chosen is the best. While I’m an advocate of using sandpaper on granite for sharpening, I’m also a firm believer that nearly every sharpening system is valid. Whether you are using waterstones, oilstones, diamond hones, sandpaper, powered disks, or grinding wheels, they all can make chisels and irons scalpel-sharp—with practice.

The important aspects of a good sharpening system are simplicity, familiarity, and availability.

The important aspects of a good sharpening system are simplicity, familiarity, and availability.

An overly complex sharpening regimen that requires multiple setups or complex jigs can lead to frustration and offers too many chances to wreck an edge rather than enhance it. Keeping the process simple is the best way to achieve a quick, keen edge.

Familiarity with any process is essential and the only way to become comfortably familiar is with practice. Practice sharpening and then practice some more. Like any discipline, you can’t understand and perform good sharpening by simply buying the “right” equipment and reading a book or watching YouTube videos. It takes hours of dedicated practice to understand what works for you with your system. When I want to spend some quiet time in my shop and don’t feel like working on a project, I sharpen stuff. Sharpening is a pretty low-stress task and requires enough concentration that you can get lost in the process for hours. Sharpening can be both meditative and productive, and you get consistently better at it.

One of the best things I’ve done for my sharpening system is to make it mobile. When I had a big shop, it seemed I was always far away from my sharpening station. So I would push a slightly dull edge until it was truly dull—with the resulting catastrophes that a bad edge can cause—before I’d take the long walk across the shop to my sharpening equipment. To cut down on the mileage and maintain my edge, I bought a three-drawer roll-around tool cabinet for $60 and turned it into a mobile sharpening system. I can hear it now: “You’re a woodworker and you BOUGHT a cabinet?” Yes, for less than the price of a good set of casters and three sets of drawer guides I bought a very serviceable solution, but I DID add a white ash and cherry top for holding my granite blocks!

I have four stones on the cabinet, so it allows me to have eight different grits at hand (both sides of the stones have abrasive paper attached). The stones are the size of a full sheet of sandpaper (9 in. by 11 in.) for adequate room to use my honing guide or flatten and polish chisel or blade backs. The drawers hold all my sharpening jigs, camellia oil, sandpaper, adhesive, and other necessities. I also keep all of my card scrapers, cabinet scrapers, and the equipment needed to keep them sharp in the cabinet.

I move the cabinet to where I’m working and my tools stay sharper. When I have all my sharpening stuff at arm’s reach, I find that I am frequently honing and refining edges. I don’t have to interrupt my work process to put that sharp edge back on a chisel or plane blade.

If your sharpening system consists of just a couple of stones and a jug of water, having a dedicated space that can be close at hand will result in better sharpening habits. And the drawers will be useful for storing bench hooks, shooting boards, and all the little tidbits that always seem to be in the way on the bench.

For those interested in sandpaper on granite (or glass), here’s how I use my system. The sandpaper is glued to the granite with 3M #77 spray adhesive. Apply the adhesive to the back of the sandpaper, place it on the granite, and use camellia oil as a lubricant on the paper when sharpening. Camellia oil is vegetable oil, won’t cause finishing problems, won’t rust your tools, and helps keep the sandpaper clean and cutting for a long time. When the paper finally wears out, pull up a corner and use a hair dryer to soften the exposed glueline. It takes just a few seconds to remove the sheet. Clean the glue residue off the granite with naphtha or acetone and put fresh paper on the stone. It takes less than a minute to replace the paper. I use 3M or Mirka paper but any high-quality paper will work fine. And I always use a honing guide. It keeps my stuff sharpened at consistent angles with sharp, square corners, and it’s fast (with a little practice).

If you have a question or a topic you’d like Rollie to cover, email [email protected].

Fine Woodworking Recommended Products

Woodriver Rechargeable Desiccant Bag

Wen Diamond Grinding Wheel

Comments

I'm curious - I have never seen a surface plate that is certified flat on both sides. What are you using? Do you care? Is it flat enough on the back side (I've never checked)?

Also, I'm curious about the sandpaper you are using. I have taught hand tools and sharpening at Cerritos College for a dozen years, and every time someone comes to me with a tool sharpened using sandpaper, I can tell right away what system they used. The edges are always just a bit rounded, due to the compressibility of the paper. So, are you okay with that, or have you come up with a way to avoid it? Are you using mylar-backed "paper" that doesn't compress?

Excellent discussion and suggestion.

Carl_Stammerjohn's comment on "compressible" paper intrigued me.

For decades, I have used wet-or-dry "sandpaper" mounted with spray adhesive on plate glass and float glass plates. I've never had a problem with rounding the corners on either narrow or wide blades. I have not tried other types of sandpaper for this purpose.

However, if an inexperienced sharpener tries to sharpen a narrow chisel blade on ANY medium, the corners (or at least one of the corners) typically will round over. The solution is a decent sharpening guide. At least this has been my experience.

Thanks for the thought-provoking comment.

I wonder how much rounding over with sandpaper systems comes from too much pressure on the push stroke? In theory at least, if there is only pressure on the pull stroke you should be safe.

That's an excellent point about when you sharpen. I tend to think of sharpening as a project I need to schedule. I also find myself with not enough time in the evening to build or mill wood, but sharpening a few tools would fit right in.

I use high quality paper (thin, consistent thickness) with a light coat of spray adhesive to adhere them to the granite. I've never had any problems with rounded edges or secondary bevels. NEVER use PSA type paper, too squishy and a person will end up with unintentional secondary bevels and rounded corners. Also cheap sandpaper is a problem because it typically has heavier (squishy, lumpy) paper and less than wonderful abrasive material.

By using Camellia oil as a lubricant I can use any type of sandpaper for sharpening, no need for wet-or-dry paper, plus the paper keeps cutting for an amazingly long time.

The blocks I use may not be machinist flat on the back side but are machined flat enough to do a fine job of sharpening. How flat do waterstones and oil stones stay?.... I've never had to flatten a granite stone yet, or glass for that matter.

I use my honing guide by placing my thumbs on the blade, fingers wrapped around the guide body and put light pressure on the push stroke (pushing away from the sharp edge) and no pressure on the return stroke. Keeping my thumbs right at the edge makes it easy to keep even pressure, the blade doesn't skew in the guide, and I never have to worry about overheating the edge if I'm aggressively removing a ding or chip on coarse paper.

Great post Rollie! What grit sequence do you like to use?

Hi Rollie, Where did you find a $60 cart? HD, Harbor Freight, Lowes etc. all seem to be way more. Did you buy used? Thx

Hi Mike, The grit sequence depends on what I'm working on but typically I have 400, 600, 800, 1200, 1500, 2000, 3000. The 3000 grit is smaller sheets, about 3x9, I haven't found a source for full sheets in the really fine grits. 5000 grit is also available.

I occasionally have 120 and 240 grit on a couple of stones for taking chips out of plane blades or aggressive reshaping, but like sanding wood I always follow the grit sequence through my final grit.

JMsidhu, I bought the cart at Sears on sale. I think it normally sells for $99 but a few times a year they put them on sale. Maybe Black & Decker will keep doing the sale thing, who knows!

I use a hybrid setup of sandpaper on granite (hold with blue painter tape), an Arkansas oil stone and water stones with a nagura block. I rarely use my low speed grinder. I would love a dedicated cart; yours gives me ideas, thanks.

Sandpaper works just fine for tools. It is more about technique than the grit carrier. I restore and hone straight razors, professionally and can put an edge on a razor with “sandpaper” that no “stone” comes close to for sharpness.

But razor edges are much more than just sharp, sharp is easy.

Stones and sandpaper substrates do not need to be dead flat. Any tool will ride on the high spots. Dead flat for sharpening is a myth. Flat-ish and smooth is good enough, MDF or a big box Marble tile or glass is plenty flat for sharpening. Sharpen to 1k and polish on any good metal polish and MDF or leather.

“I wonder how much rounding over with sandpaper systems comes from too much pressure on the push stroke?”

So, don’t push, just pull.

Good series Rollie. Keep it simple.

Log in or create an account to post a comment.

Sign up Log in