Lighter, Stronger Frame-and-Panels

Derived from Chinese casework, this frame-and-panel approach combines the best attributes of a solid plank door and a traditional frame-and-panel

Derived from Chinese casework, this frame-and-panel approach combines the best attributes of a solid plank door and a traditional frame-and-panel. A solid door will never sag, but will move and warp. Traditional frame-and-panel solves that problem, but is not as rigid. This method uses battens that tie into the panel with sliding dovetails and into the stiles with mortise-and-tenon joints. The result is a rigid construction that, while still free to expand and contract, will never rack.

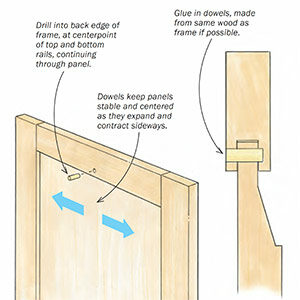

The main virtue of a solid plank door is rigidity. It will never sag. Of course, solidplank doors have serious issues with wood movement and warping, and frame-and-panel construction was invented to solve those problems, cleverly combining the simplicity of a solid panel with the dimensional stability of a rail-and-stile frame. Yet frameand-panel construction has its own limitations. In a traditional frame-and-panel, the panel is dead weight—left unglued so it can move with the seasons, it simply fills the center of the frame, adding no strength to the structure and relying entirely on the frame joints for strength. Chinese cabinetmakers figured out a way to harness the power of a floating panel. For many centuries, they’ve been using a type of frame-and-panel construction that has both the rigidity of a plank and the stability of a frame. They use it for a cabinet’s doors, sides, top, and bottom, and also for table tops and even chairs. Although their panels are typically thin and their frames elegantly slender, the resulting structures are insanely strong, even when assembled without glue. The secret is simple: battens.

The Chinese frame-and-panel has battens that tie into the panel with sliding dovetails and into the stiles with mortise-and-tenon joints. Thus the panel, while still free to expand and contract, lends its rigidity to the frame, strengthening the whole unit. Are you sitting down? That means the frame can never rack. The stress, instead of being isolated in the corner joints, is now distributed throughout the whole. So even a large door can have a thin, delicate frame and it will not sag over time. Simple, yet genius. Yes, there is more work to this design, but the structural and aesthetic benefits are huge, and I have a foolproof method for producing the tapered sliding dovetails quickly and precisely.

Fine Woodworking Recommended Products

Suizan Japanese Pull Saw

Pfiel Chip Carving Knife

Veritas Standard Wheel Marking Gauge

Comments

i love Andrew work, i love how he uses Japanese tools and some machines tools and that is my goal as a woodwork to get to the stage.

thanks Andrew and FW for this article

That wardrobe is my next project, any plans available?

I'd like to see some suggested dimensions. For example what is the panel thickness? The frame thickness etc.

In the "Interlocking Chinese Joinery" video he said the panel was 3/8" thick.

Log in or create an account to post a comment.

Sign up Log in