A closer look at Rollie’s budget vacuum pump

How to clamp and press on a woodworker’s budget

In the last episode of Talking Tools, I showed how to build quick and easy vacuum clamps. In answer to a reader’s question, I said I would outline my pump setup in the next Talking Tools. So here it is.

The pump I use is a Welch Duo-Seal that I bought from a university lab. The university was cleaning out excess equipment and I paid $50 for the pump. It’s a bit of an oldie, probably from the 1980s, but it had been rebuilt and was in fine working order. And it was a pretty good deal for a pump that still sells new for $2,990. That’s the beauty of this system; there are lots of good used vacuum pumps that go for little money and they are pretty bulletproof. I just checked eBay and my local Craigslist and found a couple of Welch pumps for under $150 and some smaller pumps as cheap as $30.

The rest of the setup is pretty straightforward. I bought everything but the duplex switch and supply tank from Veneer Supplies. Here’s the list of supplies that you will need:

- H.D. vacuum gauge 1/4-in. NPT

- Vacuum controller 1/8-in. NPT

- 30-amp vacuum control relay

- H.D. check valve 1/4-in. NPT (in and out)

- Vacuum damper for large pump (only needed if you score a large pump, won’t need if you have a small pump)

- Inline vacuum pump filter (40 micron)

- Ball valve 1/4-in. NPT

- Leviton 5245 Duplex Style 3-way combo switch/receptacle 15 amp

- New 20-lb. propane tank

- 3 – 1/4-in. NPT cast Tee

- 2 – 1/4-in. NPT to 3/8-in. barbed fitting

- 1 – 1 in. 1/4 NPT nipple

- 1/4-in. NPT to 1/8-in. NPT reducer (for vacuum controller/vacuum adapter)

- 3/8-in. braided HD plastic hose (a foot or so)

- Adapter for propane tank to 1/4-in. NPT male

It looks like a lot of stuff but you can buy the works new for under $200. One word of caution: Don’t try to repurpose a used propane tank. I had one I wasn’t using, cleaned it out with some solvent, then soap and water, and proceeded to foul the air in my shop the first time I used the system. The scent in propane is from Ethyl Mercaptan and it’s about impossible to clean it all out, and it stinks. So spend the $25 and keep your shop smelling sweet.

Here’s what all the plumbing looks like:

Notice that I use a quick-coupler after the ball valve for attaching my vacuum hose. I use a hydraulic 2-way quick coupler; they work with positive or negative pressure so I can disconnect a vacuum bag without losing the vacuum. A barbed fitting will work, but not as easily.

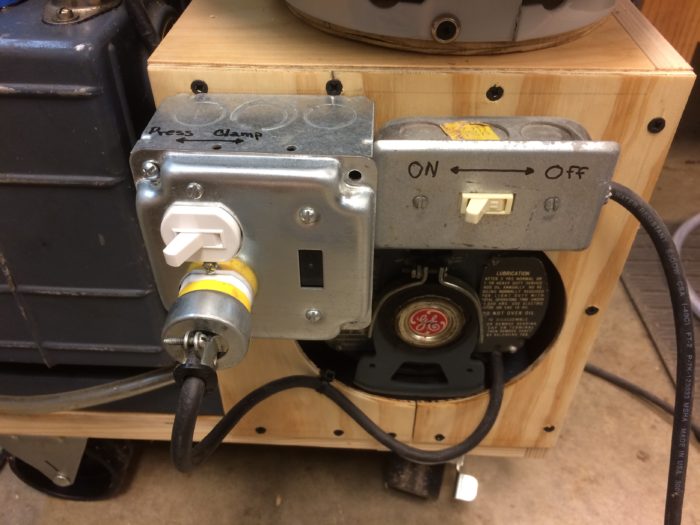

When you wire the system, use a single pole switch to control the power to the setup. The duplex 3-way switch is wired so one side controls the motor directly from the power source for continuous operation and the other side controls the vacuum switch/vacuum control relay. The relay fits next to the duplex switch in the deep box. There are good wiring diagrams on the Veneer Supplies site.

I built my setup as compact as possible and mounted it on some large casters (two fixed, two steerable) so it will roll over extension cords and work mats easily.

I’d like to give a shout-out to my good friend Dr. Glenn Street, who was the inspiration and wiring guru for the system.

Fine Woodworking Recommended Products

WoodRiver 3" Edgeband Spring Clamp

MicroJig Matchfit dovetail clamps

Veritas Wheel Marking Gauge

Comments

As a Professional Engineer, I would caution recommending that your readers use a pressure vessel (propane tank) for a vacuum application. The forces on a vacuum vessel are different than the forces on a pressure vessel. Think of a 2-liter bottle, you can probably buckle the sides in by sucking on it, but can't pop it by blowing in it. I have seen tanker trucks and storage vessels crushed like tin cans when subjected to vacuum. When the tank fails, it fails without warning, and can be very dangerous. Search "tank truck implosion" on YouTube to see what I mean.

Tinyhappygreen, all new propane tanks must be purged using vacuum before being filled for the first time. The recommended purge is to apply vacuum until it reaches at least 26 inches of mercury. A one way valve keeps air from entering the tank as the propane is used. My guess is that holding vacuum shouldn't be a problem.

TGP - Transportable propane tanks are really over-designed. While it is true that when pressurized, the tank material is under tension, try pressing as hard as you can on the side of an empty tank with your finger tip. (You can easily achieve over 100 PSI.) It won't even begin to deflect, and that is 6x the external load the tank will experience under vacuum. (And that is a point load.) Remember that the steel is over 0.100" thick. There is no way 14.7 PSI is going to deform it.

What is the smallest pump, in terms of CFM, that will work with this setup?

Log in or create an account to post a comment.

Sign up Log in